Parametric modeling method suitable for end part coil of generator stator winding

A generator stator, parametric modeling technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficult stator winding end structure finite element analysis, complicated operation process, difficult to modify, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] In order to make the present invention more obvious and understandable, the present invention will be further described with preferred embodiments.

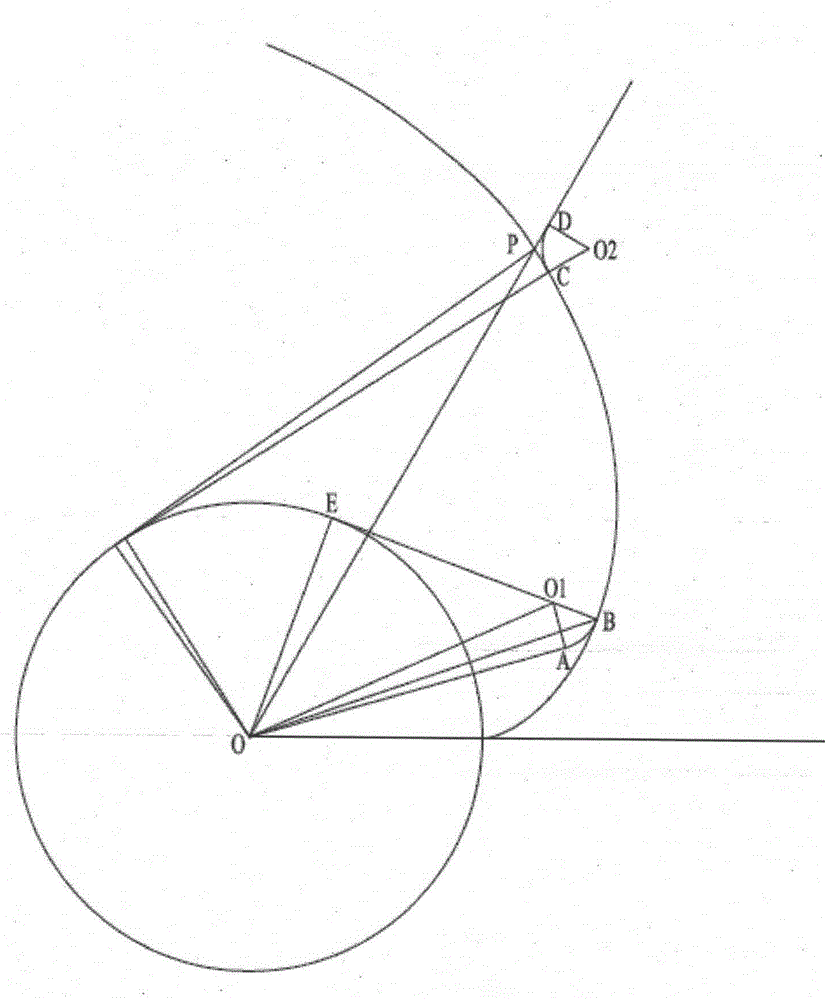

[0114] The invention provides a parametric modeling method suitable for the end coils of the stator winding of the generator, the steps of which are as follows:

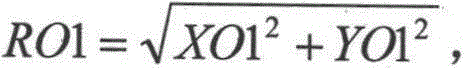

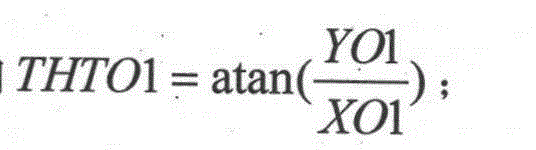

[0115] Step 1. Input the geometric parameters of the coil, including the total coil section width ECBW, the coil section total height ECBH, the coil section copper wire partial width ECBCW, the coil section copper wire partial height ECBCH, the coil section hollow copper wire hole width ECBCHW, and the coil section hollow copper Wire hole height ECBCHH, distance from coil to core center line TECRH, coil base circle radius TECRJ, coil straight line to cone surface transition chamfer radius TECR0, coil involute start chamfer radius TECR1, coil involute end chamfer Radius TECR2, length of the straight line out of the coil TECHZ, length of the straight line before th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com