A method for phase commutation of insulating pipe bus

A technology of insulating tubes and busbars, applied in the direction of busbar/line layout, etc., can solve the problem of inconsistent installation sequence of insulating tubes, busbars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0023] A method for commutating an insulating pipe busbar, comprising the following steps:

[0024] (1) According to the layout of the main transformer and inflatable switchgear, formulate the layout plan for the laying of the insulating pipe busbar. When there is a cable interlayer, use the cable support for the cable interlayer, and make full use of the existing cable support for the layout. It is necessary Set up an independent hanger.

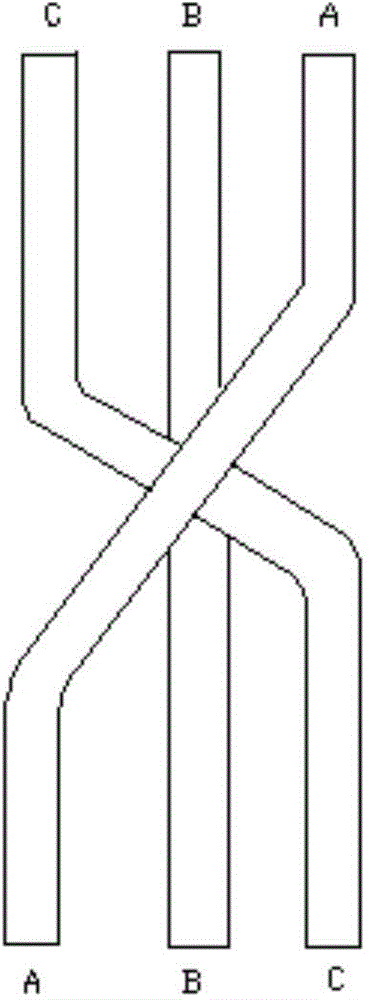

[0025] (2) According to the actual situation of the electrical connection, the commutation design is carried out within the space range with commutation conditions; the specific method is:

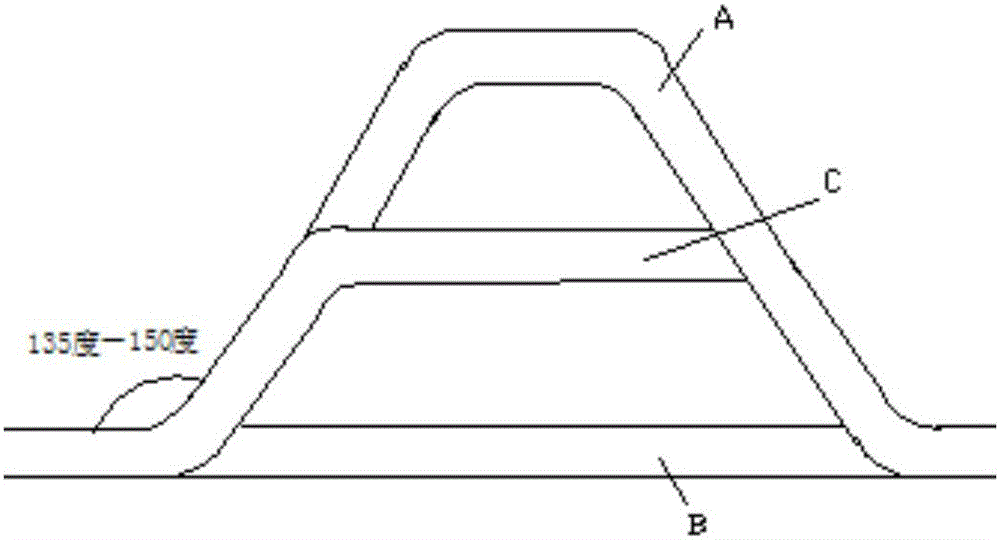

[0026] ①Choose a place with a space of not less than 80cm above the three-phase insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com