Method for processing high-yield sweet potato juice

A processing method and technology of sweet potato juice, which is applied in the processing field of high-yield sweet potato juice, can solve the problems of sweet potato juice sugar content improvement, different effects, and different means, and achieve the effects of reducing pressing time, increasing sugar content, increasing sugar content and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

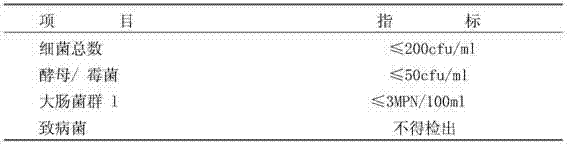

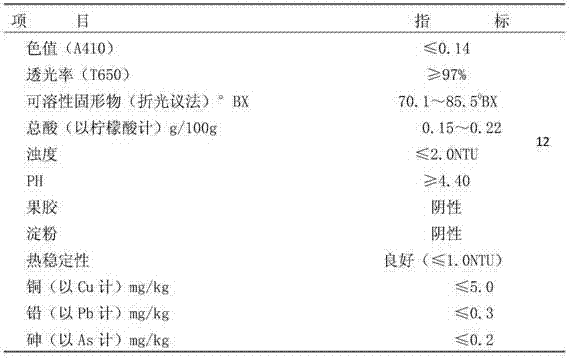

Examples

Embodiment Construction

[0027] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

[0028] The sweet potato used in the present invention is Beijing 553 variety.

[0029] The main innovation of the present invention is: the pulp and the peel are squeezed separately, the peel is squeezed twice to obtain the sweet potato juice, the pulp is squeezed three times, the pomace after the peel is squeezed for the second time, and the sweet potato juice is squeezed twice. Add it to the first pressing water, add the second squeezed skin dregs of the peel to the pulp squeezed pomace for the second pressing, and add the second squeezed sweet potato juice as pressing water to the first pressing, so that the sweet potato juice produced The sugar content is 15-20% higher than that of water used alone, which saves the subsequent concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com