Chlorine dioxide gel and manufacturing method thereof

A chlorine dioxide gel and chlorine dioxide technology are applied in the directions of botanical equipment and methods, pharmaceutical formulations, chlorine active ingredients, etc., and can solve the problems of inability to obtain chlorine dioxide gas quickly, reduction in concentration, cumbersome and inconvenient operation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

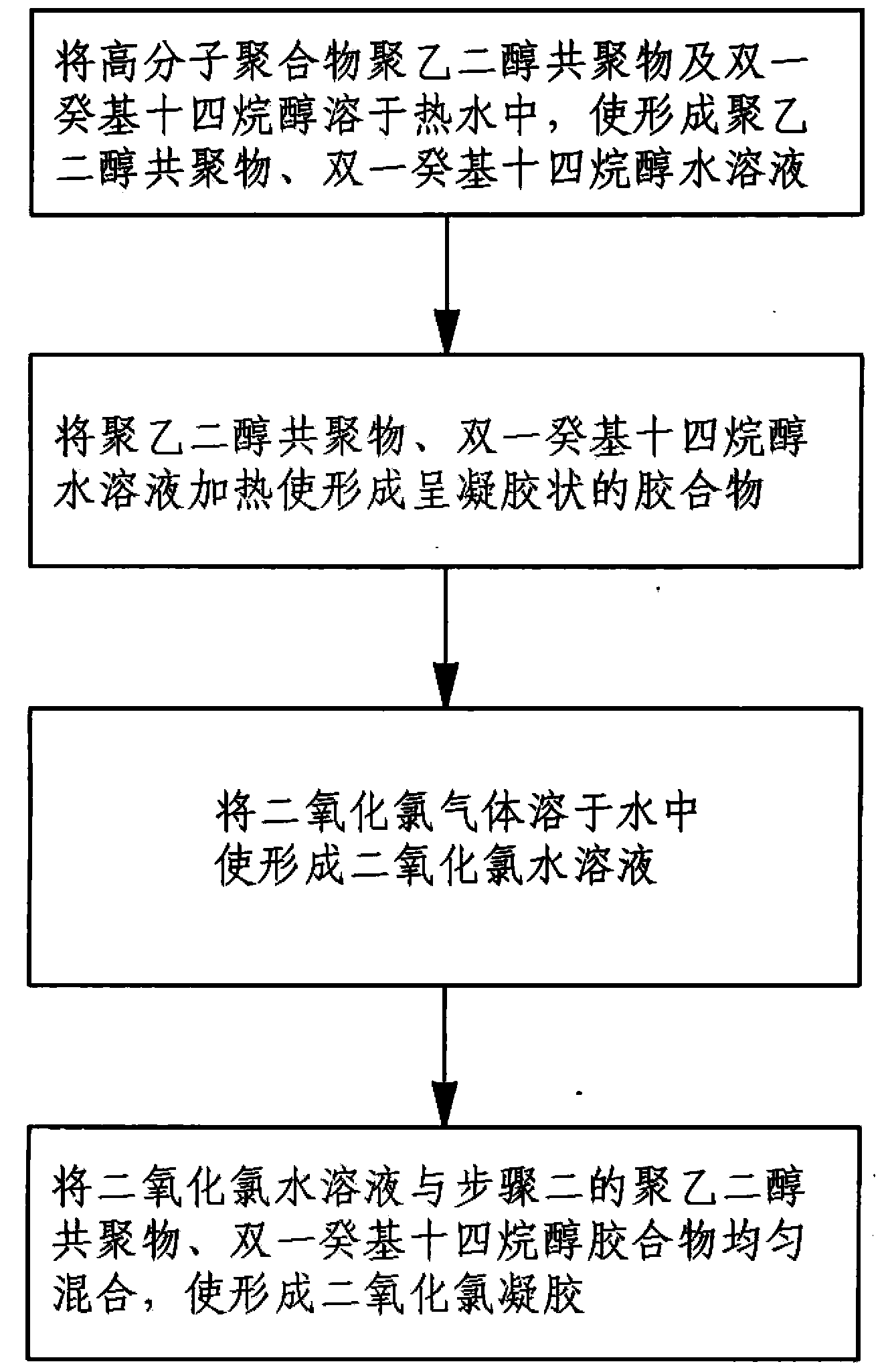

[0016] Such as figure 1 Shown flow chart, chlorine dioxide gel of the present invention and preparation method thereof comprise following steps:

[0017] Step 1: dissolving high molecular polymer polyethylene glycol copolymer and two-decyltetradecanol in hot water to form polyethylene glycol copolymer and two-decyltetradecanol aqueous solution; 50 gram of polymer polyethylene glycol copolymer and bis-decyltetradecanol are dissolved in 1000cc of hot water with a temperature of 90°C to form polyethylene glycol copolymer, bis-decyltetradecanol Aqueous alkanol solution.

[0018] Step 2: heating the aqueous solution of polyethylene glycol copolymer and bis-decyl tetradecyl alcohol in the above steps to form a gel-like colloid; The aqueous solution is heated to 90°C to make polyethylene glycol copolymer and bis-decyltetradecanol aqueous solution form a gel-like colloid.

[0019] Step 3: Dissolving pure chlorine dioxide gas in water to form an aqueous solution of chlorine dioxide....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com