Dynamic balance structure

A spindle and chute technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as unstable operation, heavy motor load, and complicated calibration procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

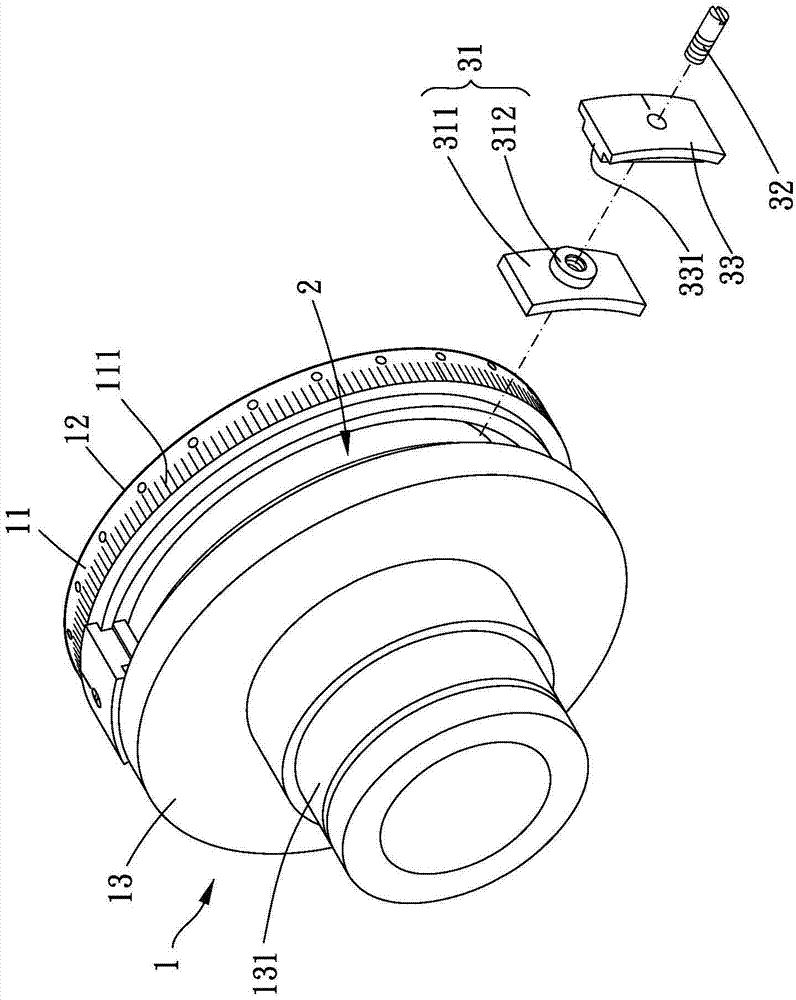

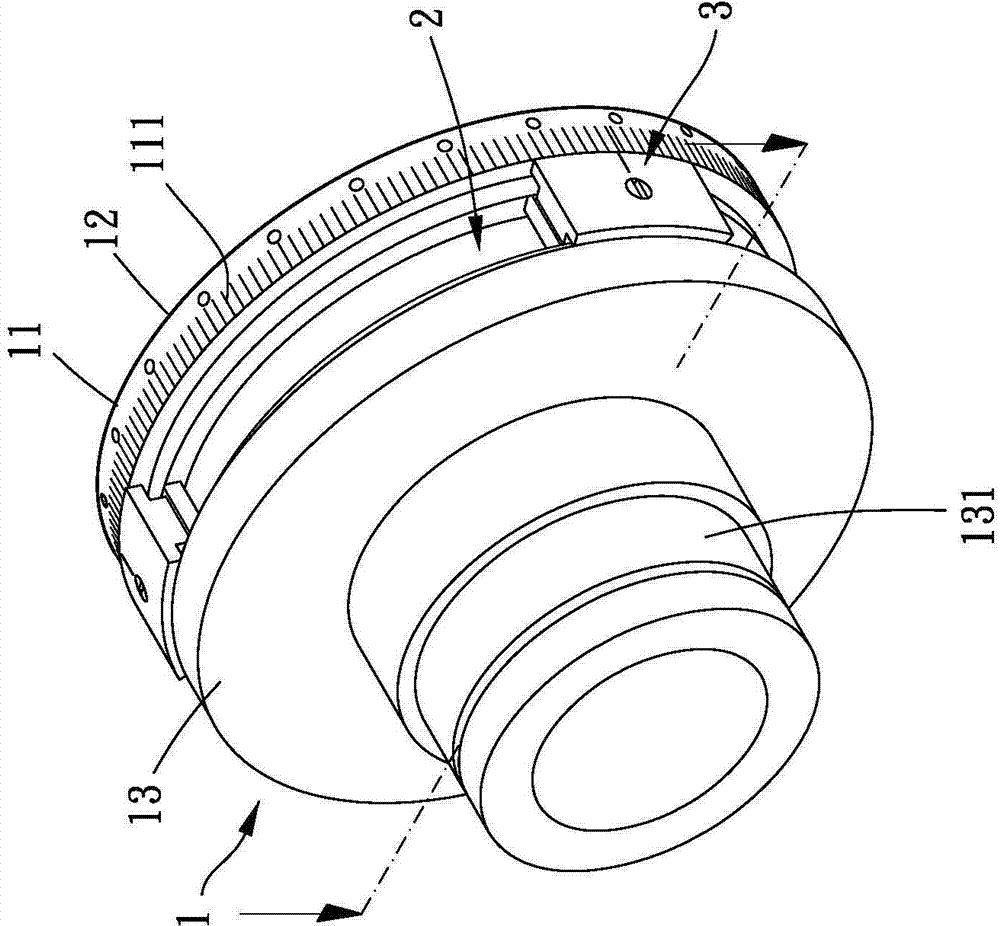

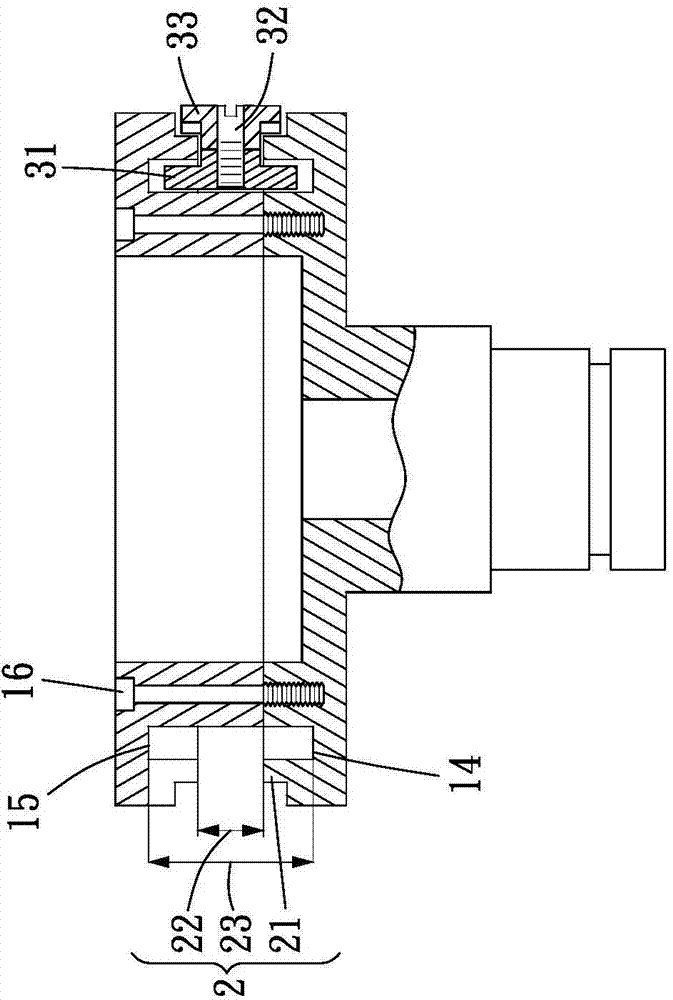

[0035] Please refer to Figure 1 to Figure 4 , the present invention provides a dynamic balance structure for setting on a machine tool (not shown), the machine tool includes a main shaft 4, the main shaft 4 defines a central axis, the dynamic balance structure includes a clamping part 1, a The chute 2 and at least one counterweight assembly 3 .

[0036]The clamping part 1 is coaxially arranged on the main shaft 4 with one end thereof, and the opposite end of the clamping part 1 is used for connecting a workpiece to be rotated (not shown in the figure), and the clamping part 1 has a The outer ring surface 11 of the clamping member 1 is a ring body and has a first face 12 and a second face 13 opposite to each other. The first face 12 of the clamping member 1 and the second face The surface 13 is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com