Internal Shear Buffer

A cushioning device and internal shearing technology, which is applied to buffers, transportation and packaging, railway car body parts, etc., can solve problems such as falling or falling out, falling off of impact protection devices, and unreasonable structural settings of vertical support devices. Achieve the effects of reducing manufacturing difficulty, facilitating inspection and replacement, and reducing retreat space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

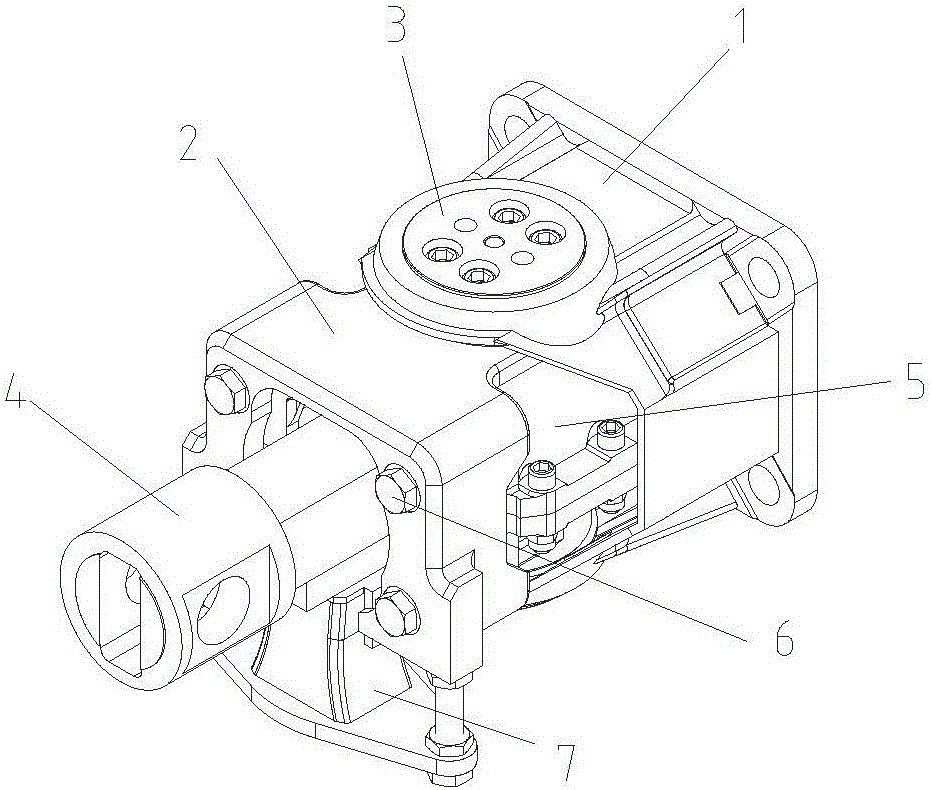

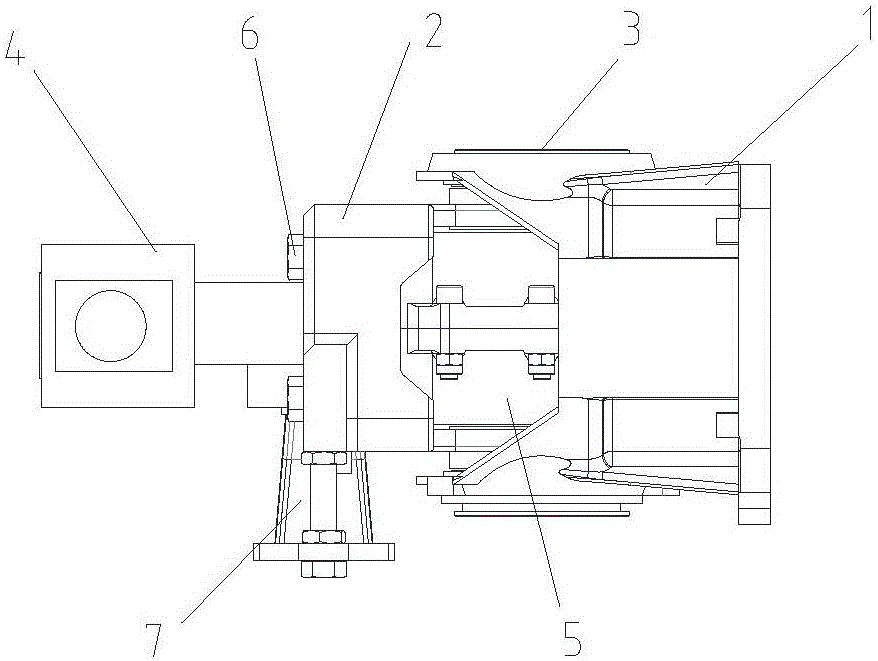

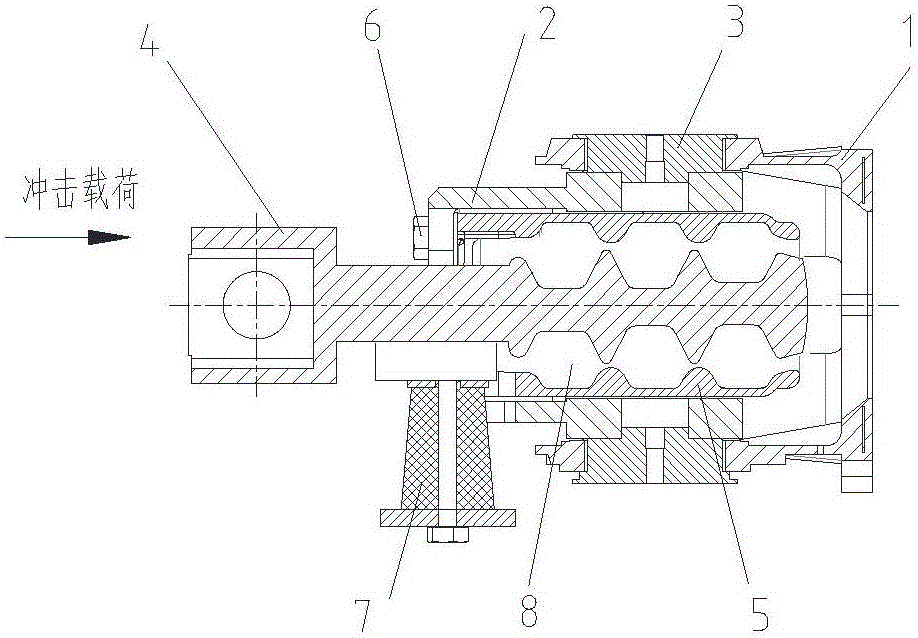

[0027] as attached figure 1 , attached figure 2 and attached image 3 Shown:

[0028] An internal shearing buffer device, comprising a buffer body connected to the coupler, a mounting seat 1 connected to the vehicle body, the internal shearing buffering device also includes an intermediate bearing seat 2 connected to the buffer body, and the mounting seat 1 It is connected with the middle bearing seat 2 through the rotating shaft 3, and the installation method of the bearing seat 2 and the mounting base 1 is that the bearing base 2 is installed inside the mounting base 1 through the rotating shaft 3; the buffer body includes a buffer housing 5 and a buffer rod 4. The inside of the buffer housing 5 is provided with a rubber block 8 covering the buffer rod 4, and the buffer rod 4 extends to the front end of the buffer housing 5; the front end of the intermediate bearing seat 2 is provided with an overload protection device 6, and the buffer The shell 5 is connected to the in...

Embodiment 2

[0033] as attached Image 6 , attached Figure 7 and attached Figure 8 Shown:

[0034] The difference from Embodiment 1 is that the mounting base 1 and the intermediate bearing base 2 are connected through the rotating shaft 3 , but the mounting base 1 and the bearing base 2 are installed in such a way that the bearing base 2 is installed outside the mounting base 1 through the rotating shaft 3 . Both the installation methods of the bearing seat 2 and the installation seat 1 in Embodiment 1 and Embodiment 2 can ensure the stable operation of the buffer device.

[0035] attached Figure 9 And attached Figure 10 A schematic diagram of the working state structure of the specific embodiment 2 of the present invention is given, and the working principle of this embodiment is the same as that of the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com