Sheet feeder and method for forming a flake flow

A sheet and refill technology, applied in the field of dividing sheets into single sheets, can solve problems such as damage, transfer, and sheets cannot be reliably separated from each other, and achieve low energy consumption, good suction effect, and simple controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

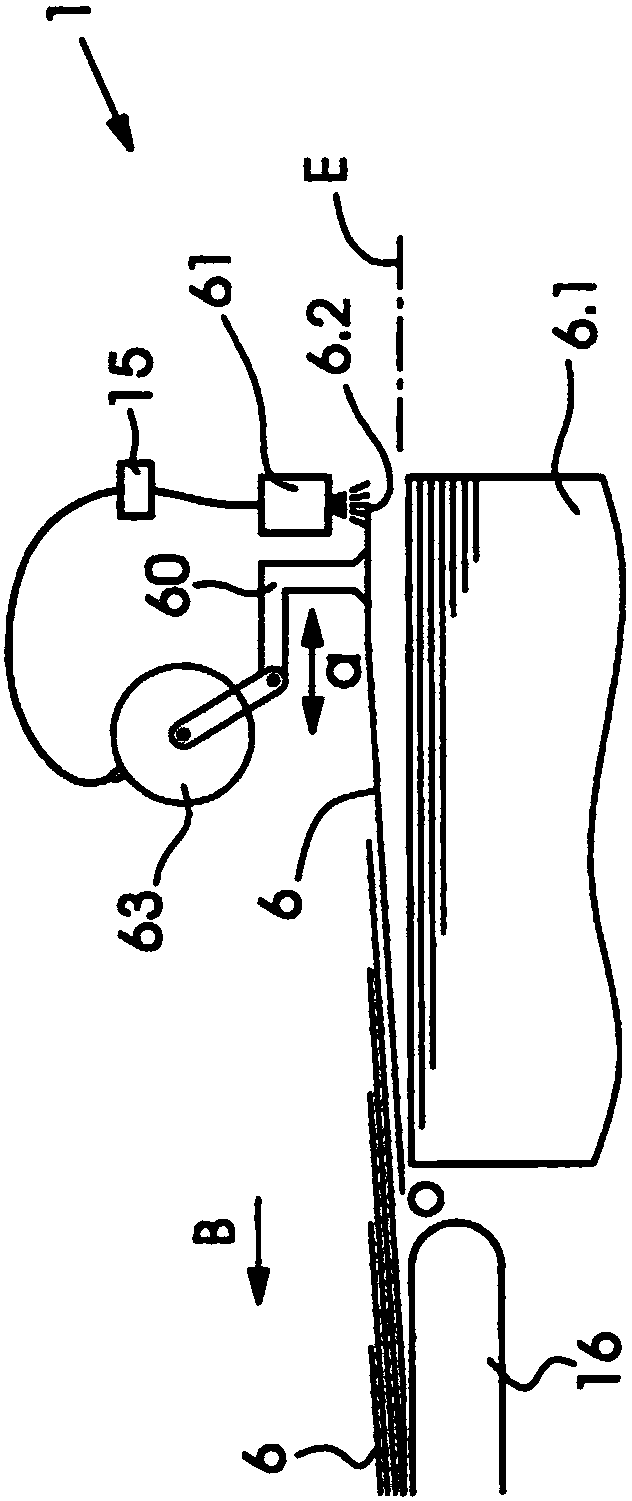

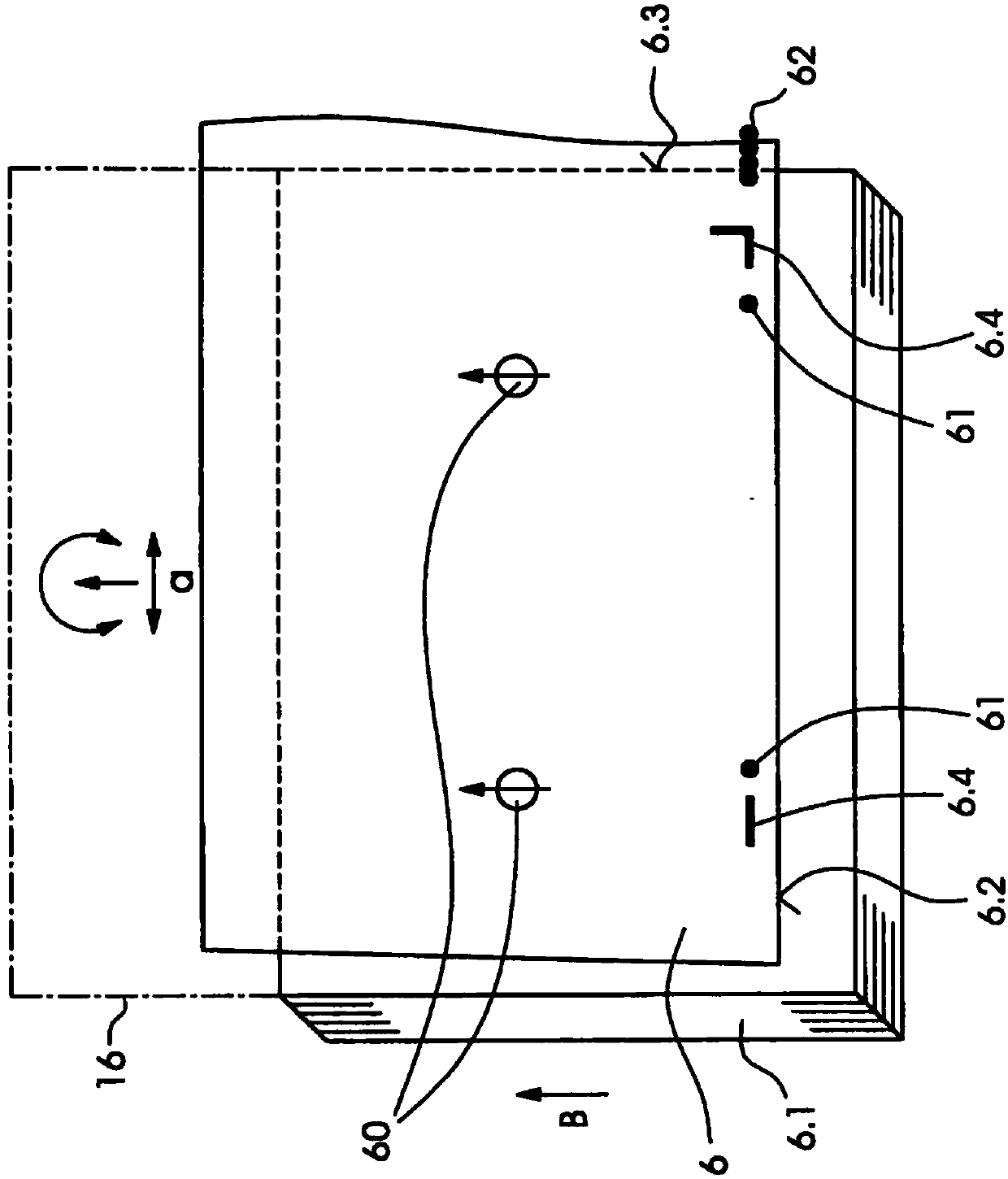

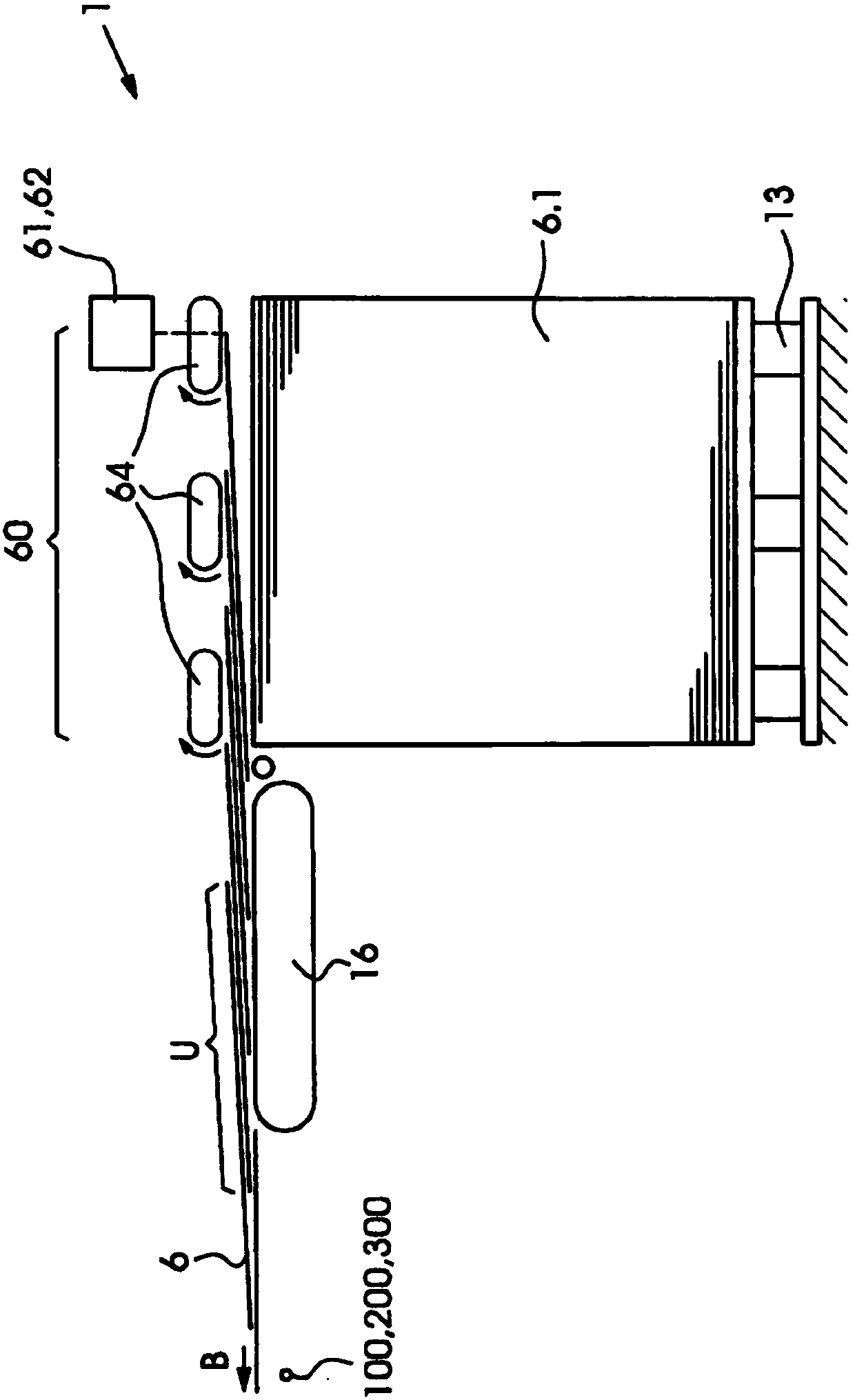

[0026] figure 1shows the method for separating the sheets 6 from the sheet stack 6.1 and for transferring the separated sheets 6 into the (tail press) lamella sheet flow for the (tail press) lamina The sheet 6 is fed further along the sheet travel direction B to the sheet feeder 1 of the subsequently arranged sheet processing machine. Above the sheet stack 6 . 1 are arranged a suction and transport unit 60 as well as a sheet detection unit 61 or 61 , 62 . Both the sheet detection units 61 , 62 and the suction and conveying unit 60 are connected to the machine control 15 using data transmission technology. As soon as the uppermost sheet 6 of the sheet stack 6 . 1 has been sucked by the suction elements of the suction and transport unit 60 , the position of the sheet 6 is detected by the sheet detection units 61 , 62 . The measurement results of the sheet detection units 61 , 62 are transmitted to the machine control 15 and evaluated there. A setpoint-actual comparison takes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com