lifting device

A lifting device and rotating parts technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems of obstructing crane hoisting, time-consuming and laborious bearing replacement, etc., and achieve the effects of simple structure, high work efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

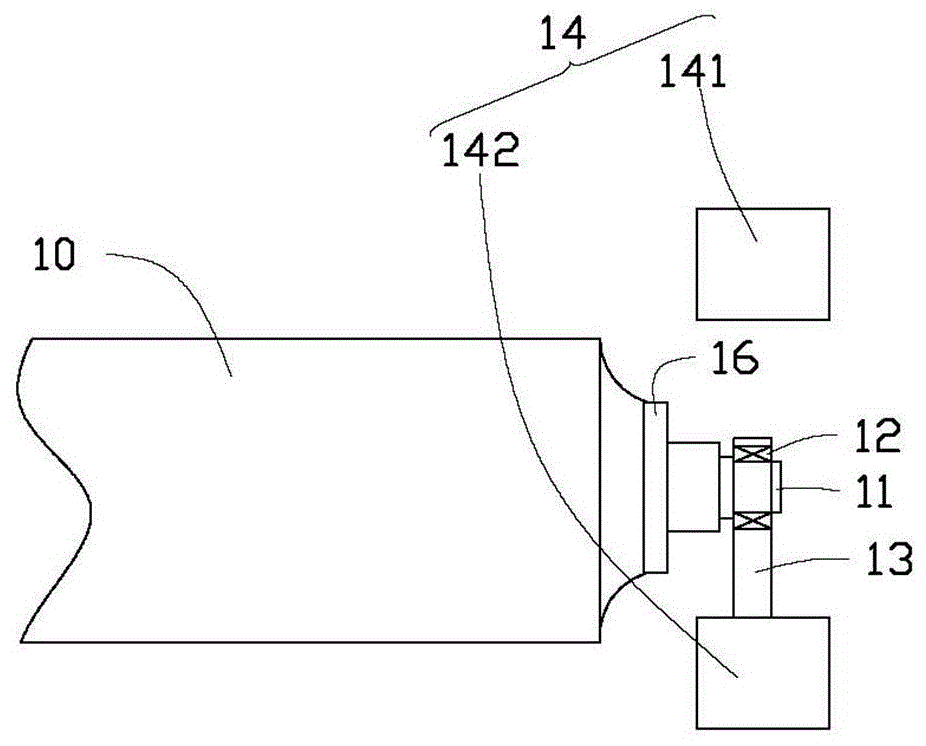

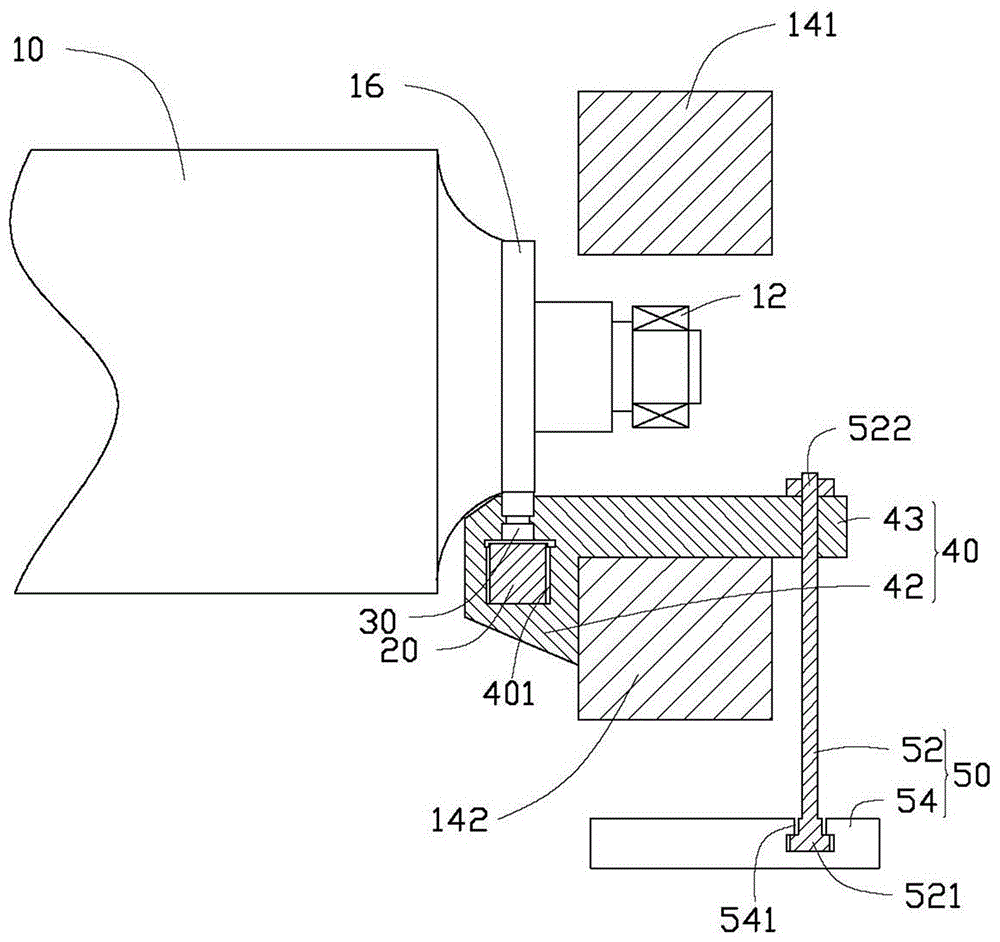

[0017] The lifting device of the present invention is used to lift and separate a large rotating part from the frame. Such as figure 1 As shown, the rotating member 10 is a drying cylinder for papermaking. The end 11 of the drying cylinder is provided with a bearing 12 , and the bearing 12 is accommodated in a bearing seat 13 , and the bearing seat 13 is then fixed on a frame 14 . Wherein the upper half of the bearing seat 13 is fixed with the upper beam 141 of the frame 14, and the lower half of the bearing seat 13 is fixed with the lower beam 142 of the frame 14. figure 1 The upper half of the bearing housing 13 shown in has been removed. When the bearing 12 needs to be replaced, the end 11 of the drying cylinder needs to be separated from the frame 14 to dismantle the lower half of the bearing seat 13 to replace the bearing 12. The existing method is to lift the end portion 11 of the drying cylinder and separate it from the frame 14 at a journal 16 of the end portion 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com