Titanium-based porous sintered composite material with nanocrystalline structure and preparation method thereof

A technology of composite materials and nanocrystals, which is applied in the field of titanium-based porous sintered composite materials and their preparation, can solve problems such as the difficulty in preparing bulk nano-metals, and achieve the effects of wide application range, high-pressure torsion speed, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

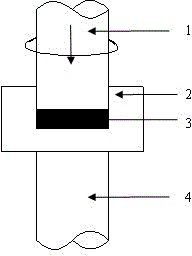

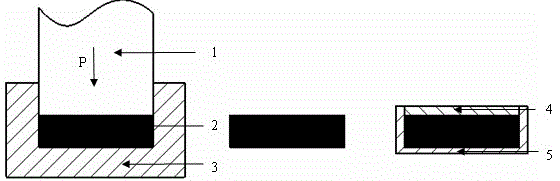

Method used

Image

Examples

Embodiment 1

[0028] Example 1, Ti-5AL-1Mo-6V titanium-based porous sintered composite material with nanocrystalline structure and its preparation method

[0029] After the titanium powder, aluminum powder, molybdenum powder and vanadium powder with a purity of 99.99wt% (weight percent) are prepared in a molar ratio of 88:5:1:6, they are extruded through a mold on a press, The blank is made into a blank with a certain strength and density (relative density is about 0.81); then it is processed into a disc-shaped sample of d8mm×0.5mm after being sintered at a high temperature of 850° in a vacuum sintering furnace for 5 hours; The sample is put into the bag, and the titanium-based porous sintered composite material with nano-grain structure is obtained through high-pressure torsion and severe plastic deformation. Ti-5AL-1Mo-6V titanium-based porous sintered composites with a nanocrystalline structure of 8 mm bulk.

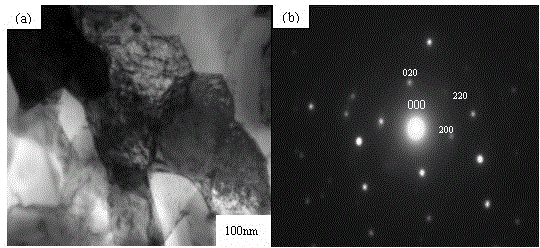

[0030] from image 3 It can be seen from the transmission electron microscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap