Lapping repair method of main cable wire of suspension bridge and lapping component of method

A repair method and technology for suspension bridges, which are applied to bridge parts, bridge repairs, bridges, etc., can solve problems such as the difficulty of the main cable wire, the easy rotation of the steel wire, and the corrosion of the main cable wire, so as to improve repair efficiency and avoid installation difficulties. The effect of less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

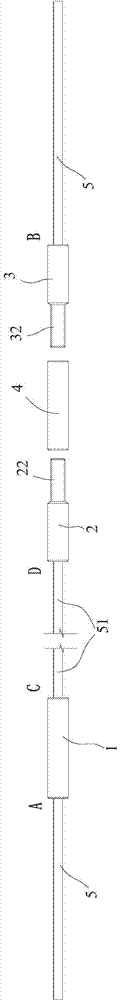

[0030] The method of repairing the main cable steel wire bridge of the suspension bridge includes:

[0031] (S1) Use a dynamometer to measure the wire tension of the main cable wire before repair;

[0032] (S2) Cut off a section of the corroded steel wire in the main cable steel wire, and the remaining main cable steel wire forms two open ends;

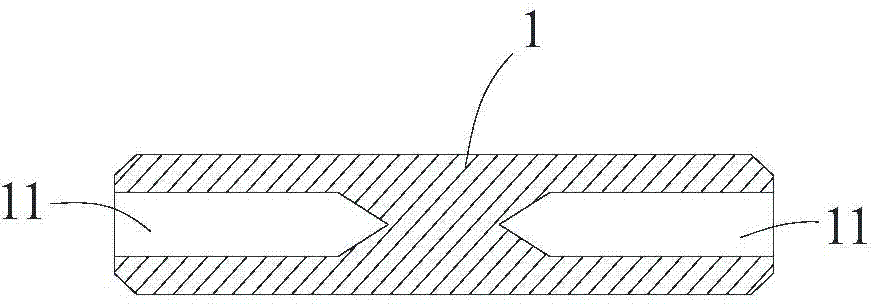

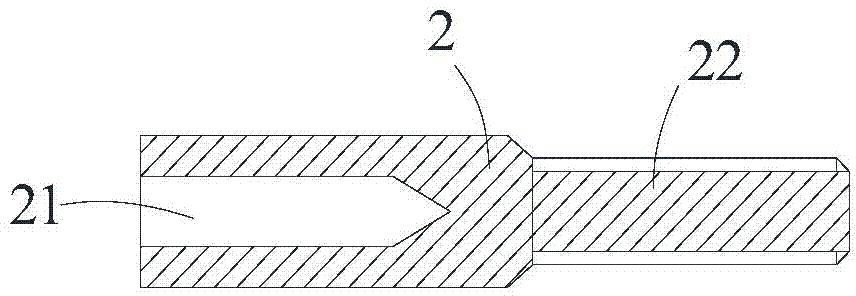

[0033] (S3) Cut the new steel wire so that the length of the new steel wire is consistent with the length of a section of the corroded steel wire. One end of the new steel wire is connected to one of the open ends with the first connecting piece, and the other end of the new steel wire is connected to the other end. the second connecting piece, and the other said open end is occludedly connected to the third connecting piece;

[0034] (S4) Threading the second connecting piece and the third connecting piece with a fourth connecting piece having internal threads at both ends, wherein the internal threads at both ends of the fourth con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com