Leveling ruler flat underboarding mortar bedding method

A technology of flat pads and square rulers, which is applied in construction and infrastructure engineering, etc., can solve the problems of low processing cost, large adjustable range, high material and processing cost, etc., so as to improve equipment installation speed, facilitate adjustment, reduce material and The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

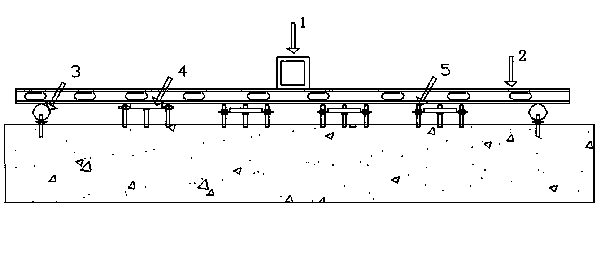

[0017] Such as figure 1 Shown: a flat ruler flat pad seat oar method, including the following steps: a. Install the adjusting bolt 5 on the concrete foundation, and place the flat backing plate 4 on the adjusting bolt 5; b. Install adjusting bolts at both ends of the concrete foundation, and place two temporary supports 3 on the adjusting bolts respectively; c. Adjust the level of the temporary support according to the actual required elevation; d. Place the square ruler 2 with the frame level 1 on the two temporary supports 3, adjust the temporary support 3 according to the reading of the frame level 1, so that the reading value of the frame level 1 is less than or equal to 0.02mm / m; e. Adjust the levelness of the flat backing plate 4, take the flat backing plate 2 as a benchmark, and use a feeler gauge to check the gap between the flat backing plate and the flat ruler, so that the gap between the flat backing plate and the flat ruler is between 0.02mm-0.05mm; f. Remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com