Bamboo structure composite plate

A bamboo structure and plate technology, applied in building components, building structures, building materials, etc., can solve problems such as waste of resources, reduce carbon emissions, have strong integrity and disintegration resistance, and save cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

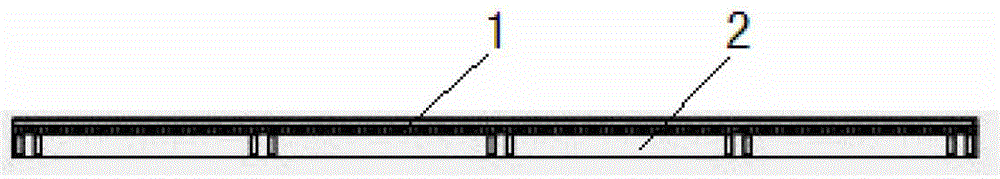

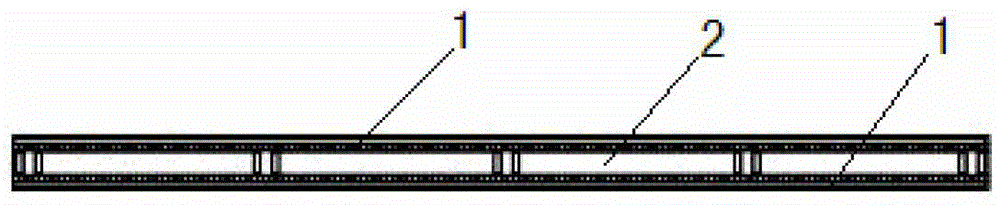

[0050] see figure 1 , with reference to figure 2 , image 3 , Fig. 4 and Fig. 5, the bamboo structure composite panel of the present invention is composed of bamboo structure skeleton and filling and covering material (not shown in the figure), and the filling and covering material is filled in the gaps in the bamboo structure skeleton and covered Around the skeleton of the bamboo structure.

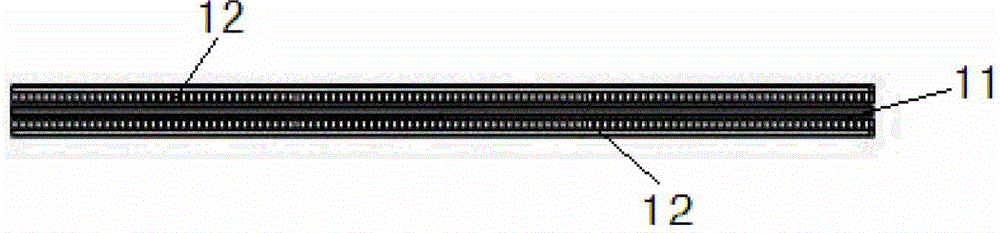

[0051] The bamboo structure skeleton in the present invention is composed of at least two bamboo structure substrates with the same or different structures; Sheet 11 , B-type bamboo structure sheet 12 and C-type bamboo structure sheet 13 . After the bamboo structure composite plate is formed, the edge protruding layer 3, the eye 4, and the falcon 5 that are used for interconnection between the plates are provided on the plate (for cooperation see Figure 14-Figure 21 ). Generally speaking, the thickness of the edge protrusion layer 3, 5 is smaller than the thickness of the plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com