Multi-gear hinge

A multi-gear and hinge technology, applied in door/window fittings, hinged panels, buildings, etc., can solve problems such as cost increase, difficulty in production and processing, and difficult multi-angle positioning, so as to improve efficiency, reduce welding processing, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

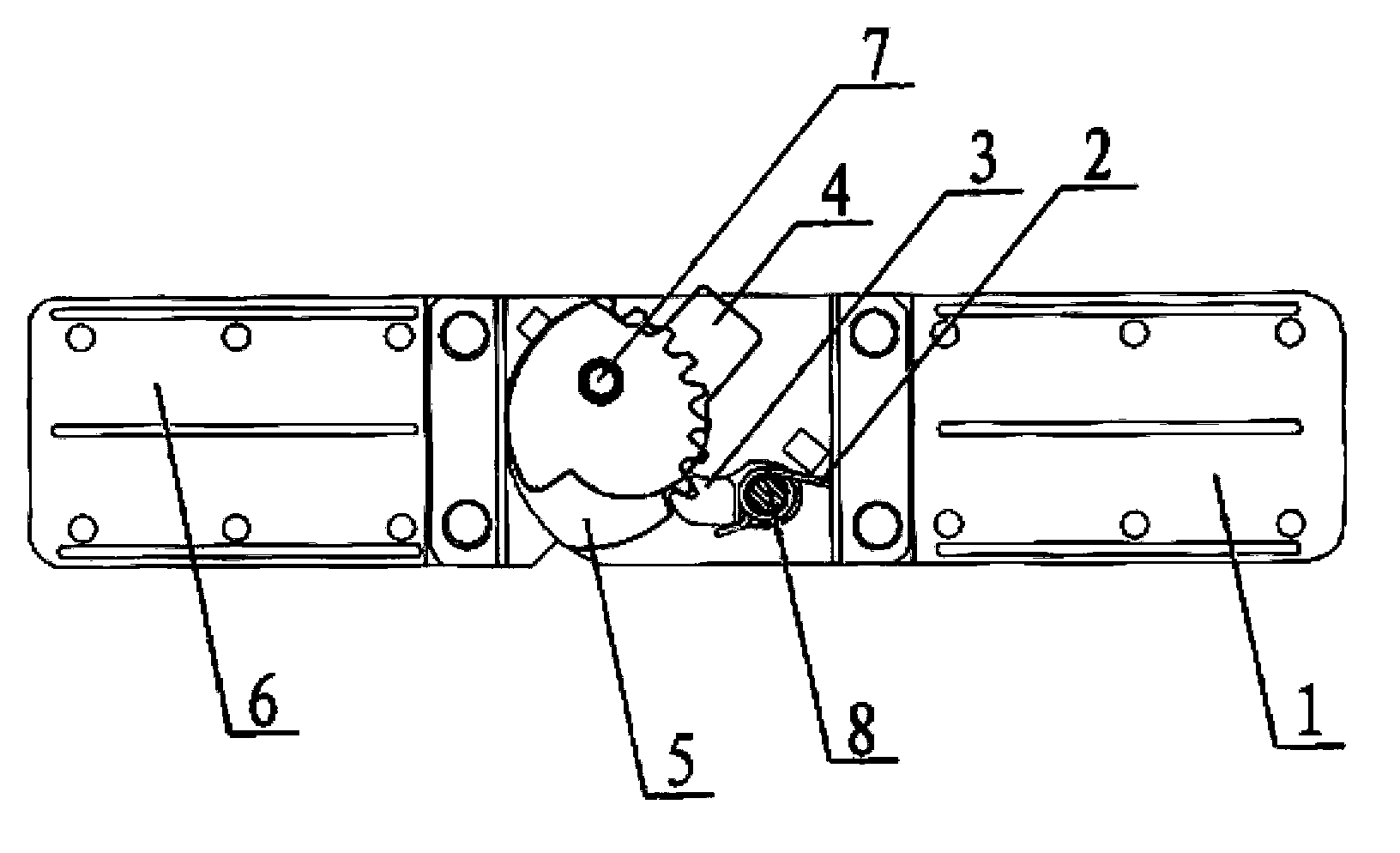

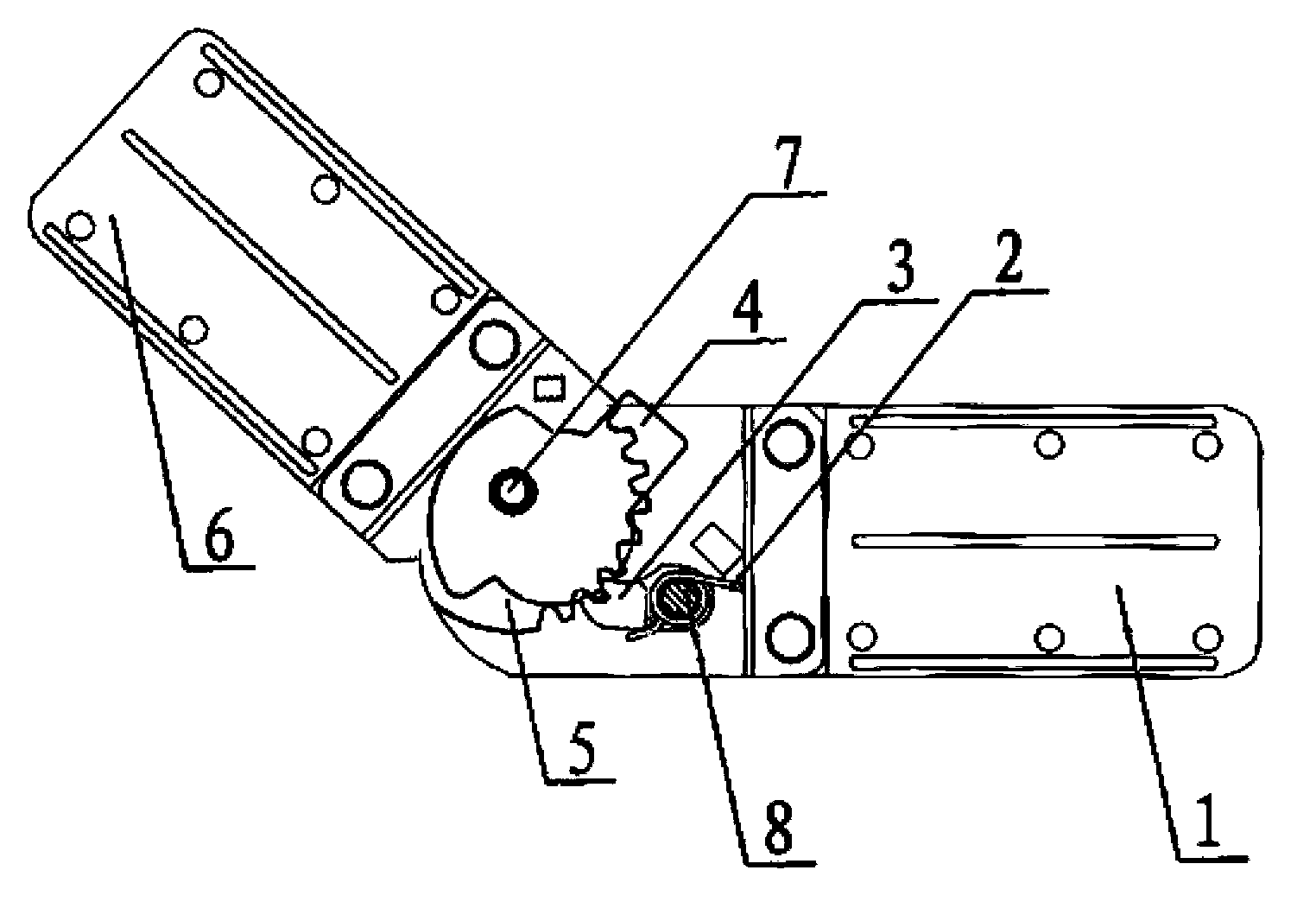

[0021] See attached Figure 1-2 , a multi-gear hinge, including a fixed chain seat 1 including a support shaft 8 and a hollow groove, a pin shaft 7 fixed on the fixed chain seat 1 through the hollow groove of the fixed chain seat 1, and a positioning gear arranged on the support shaft 8 3. One end of the living hinge seat 6 containing the hollow large gear plate 5 extends into the hollow groove of the fixed chain seat 1 and is hinged on the pin shaft 7. The return piece 4 including the impact part and the positioning part is located in the hollow of the hollow large gear plate 5. In the groove and hinged on the pin shaft 7, the fixed chain seat 1 and the living hinge seat 6 have a striker pin hole and a positioning pin hole that are respectively matched with the impact part and the positioning part of the return piece 4, and there is also a support shaft 8 The bottom of the positioning gear 3 in the middle is provided with a compression spring, through the adjustment of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com