Radome unit with buckling connection structure

A connection structure and radome technology, applied in the direction of the radiation unit cover, etc., to achieve the effect of improving wind resistance, improving rainproof performance, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

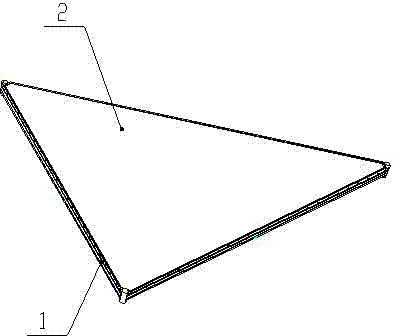

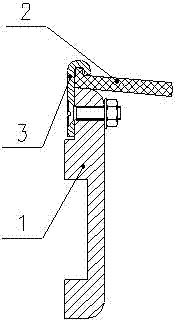

[0012] A radome unit with a crimping connection structure, comprising: a triangular metal frame 1, a honeycomb sandwich panel 2 and a bent metal buckle bar 3.

[0013] The triangular metal frame 1 is the installation base of the radome unit. It is welded by three rectangular steel plates. The sides of each rectangular steel plate are processed with light holes with a diameter of 5mm at equal intervals. on flat surface. The edges of the three sides of the honeycomb sandwich panel 2 are processed with flanging of 2mm×2mm. The bent metal buckle 3 is a bent piece of stainless steel plate. The honeycomb sandwich panel 2 is flatly laid on the triangular metal frame, the bent metal buckle 3 is buckled on the flange of the honeycomb sandwich panel, and the bent metal buckle 3 and the side of the triangular metal frame 1 are connected by screws, flat washers and nuts. Fixed connection.

[0014] The radome unit is mainly affected by wind, rain, snow and other environments when it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com