Magnetic trap for capturing magnetic impurities in high-temperature liquid metal coolant

A liquid metal cooling and magnetic impurity technology, applied in the direction of high-gradient magnetic separators, can solve the problems of wire mesh corrosion, coolant introduction, and inability to flow through the sorting space, so as to avoid erosion and corrosion and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

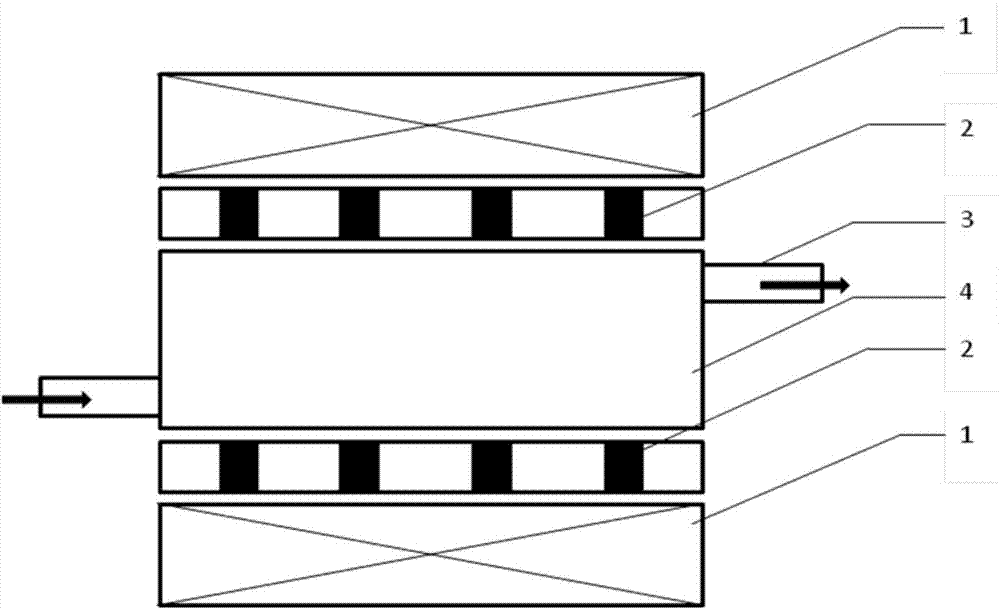

[0024] see figure 1 , the structural form of the magnetic trap used to capture the magnetic impurities in the high-temperature liquid metal coolant in this embodiment is: the non-magnetic stainless steel box body 4 with the flange interface 3 at both ends is connected in series through its flange interface 3 at high temperature In the circulation circuit of the liquid metal coolant, a ferromagnetic cylinder 2 is arranged on one side or two symmetrical sides of the nonmagnetic stainless steel box 4, and the axis of the ferromagnetic cylinder 2 is connected to the axis of the nonmagnetic stainless steel box 4. The side plate is vertical so that it is perpendicular to the flow direction of the high-temperature liquid metal coolant in the non-magnetic stainless steel box 4; a magnetic field source system 1 is arranged on the outside of the ferromagnetic cylinder 2, and the magnetic field source system 1 passes through the iron The magnetic cylinder 2 forms a magnetic impurity sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com