Mechanism and assembly method for automatic assembly of energy-saving lamp tube and lamp cap lower cover

An automatic assembly and lamp cap technology, which is applied to machines with sequential working positions, installation/removal of discharge tubes/lamp auxiliary devices, metal processing, etc. Development requirements, low efficiency and other issues, to achieve the effect of mass production, improve production efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

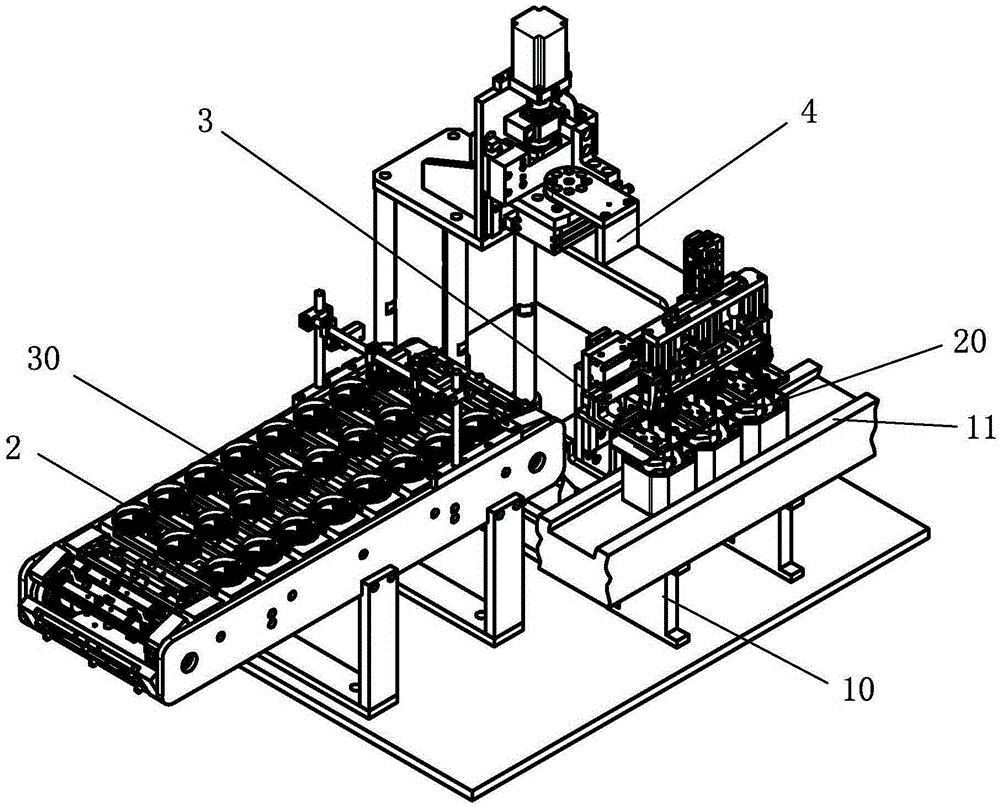

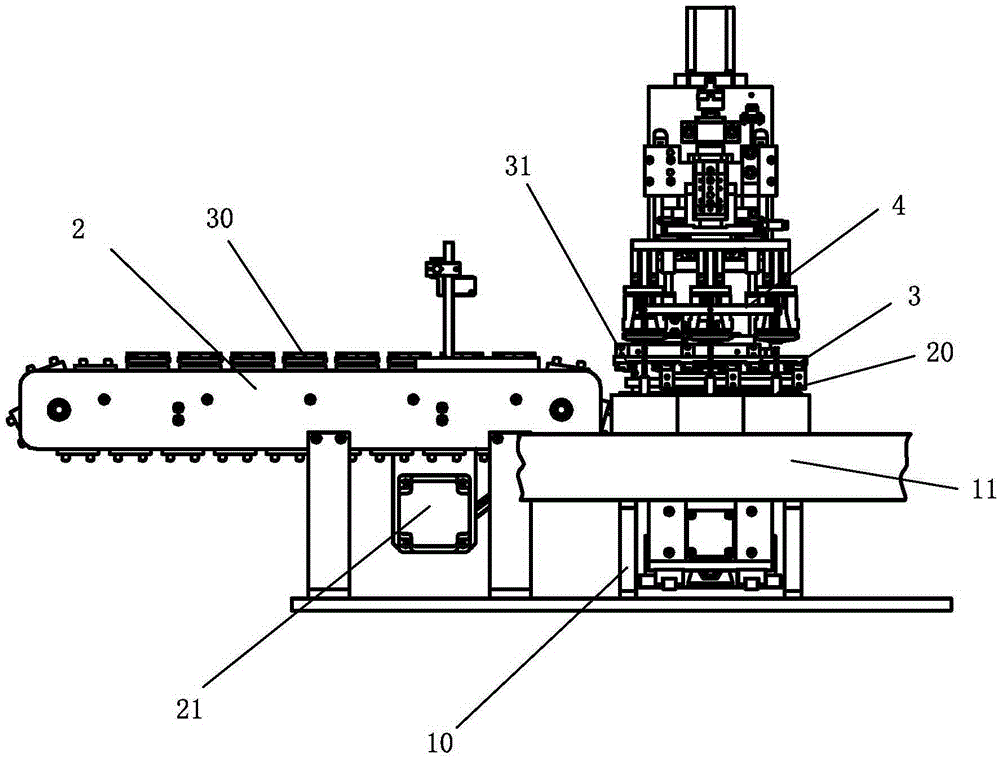

[0048] see Figure 1 to Figure 10 As shown, a mechanism of the present invention for automatic assembly of an energy-saving lamp tube and a lower cover of a lamp cap includes:

[0049] One machine 10;

[0050] A first conveying track 11 installed on the machine 10 and used to convey the energy-saving lamp tube 20;

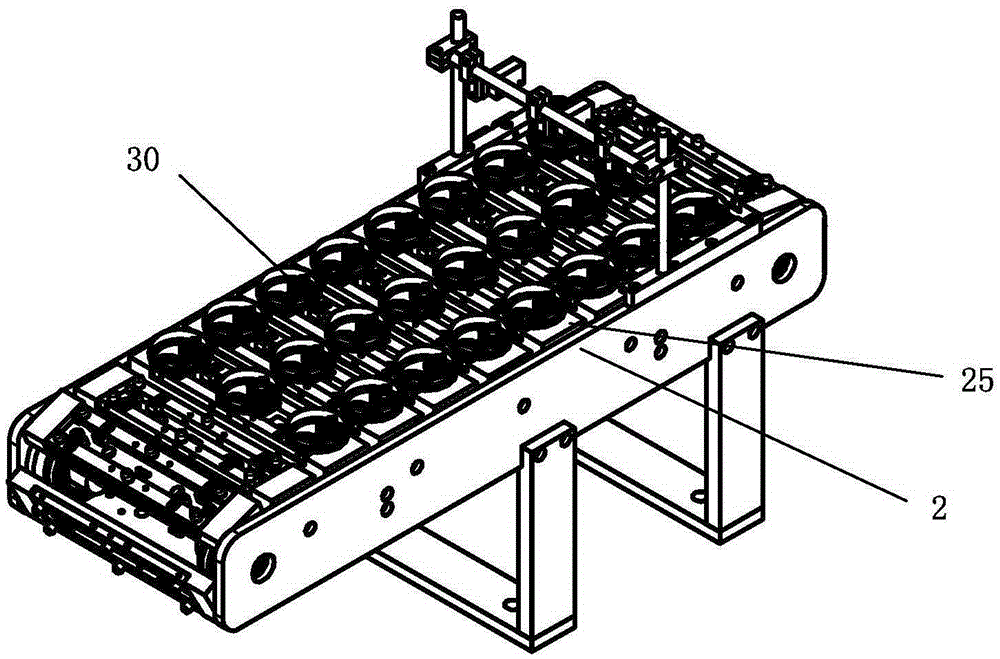

[0051] A second conveying track 2 for transferring the lamp cap lower cover 30, the second conveying track 2 is installed on the machine platform 10 and is in a position matching with the first conveying track 11;

[0052] A wire management mechanism 3, the wire management mechanism 3 has a wire management clamp 31 that can extend to the first conveying track and a pressing plate 32 that fits under the wire management clamp; on, and beside the first conveying track 11, so as to straighten the filament 201 of the energy-saving lamp tube 20; and

[0053] A lamp cap lower cover grasping mechanism 4, the lamp cap lower cover grasping mechanism 4 has a grasping robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com