Assembling method for water blocking device of grinding machine

A technology of water blocking device and assembly method, which is applied in the direction of grinding/polishing safety device, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as impact, grinding fluid splashing, etc., to reduce production costs and increase work The output and the effect of novel design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

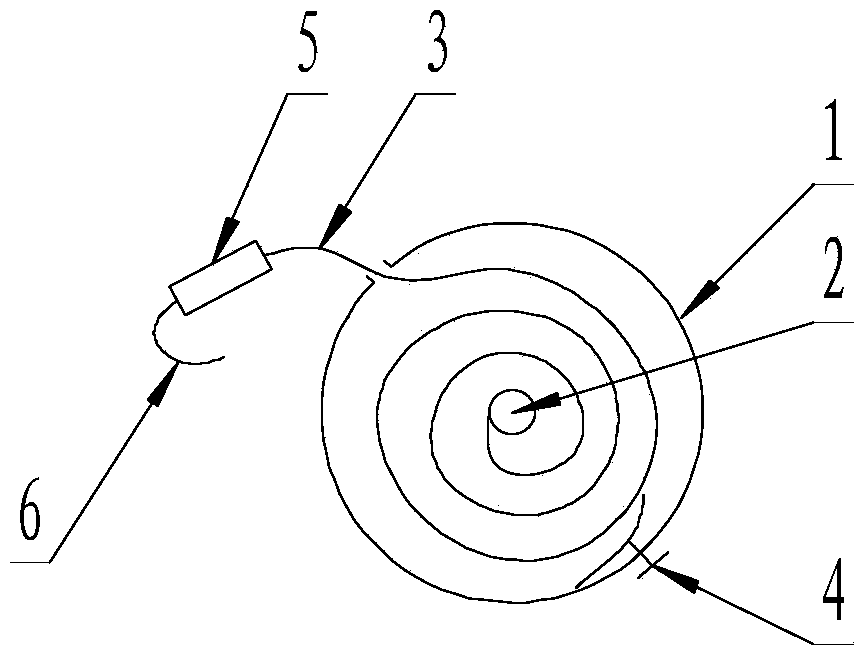

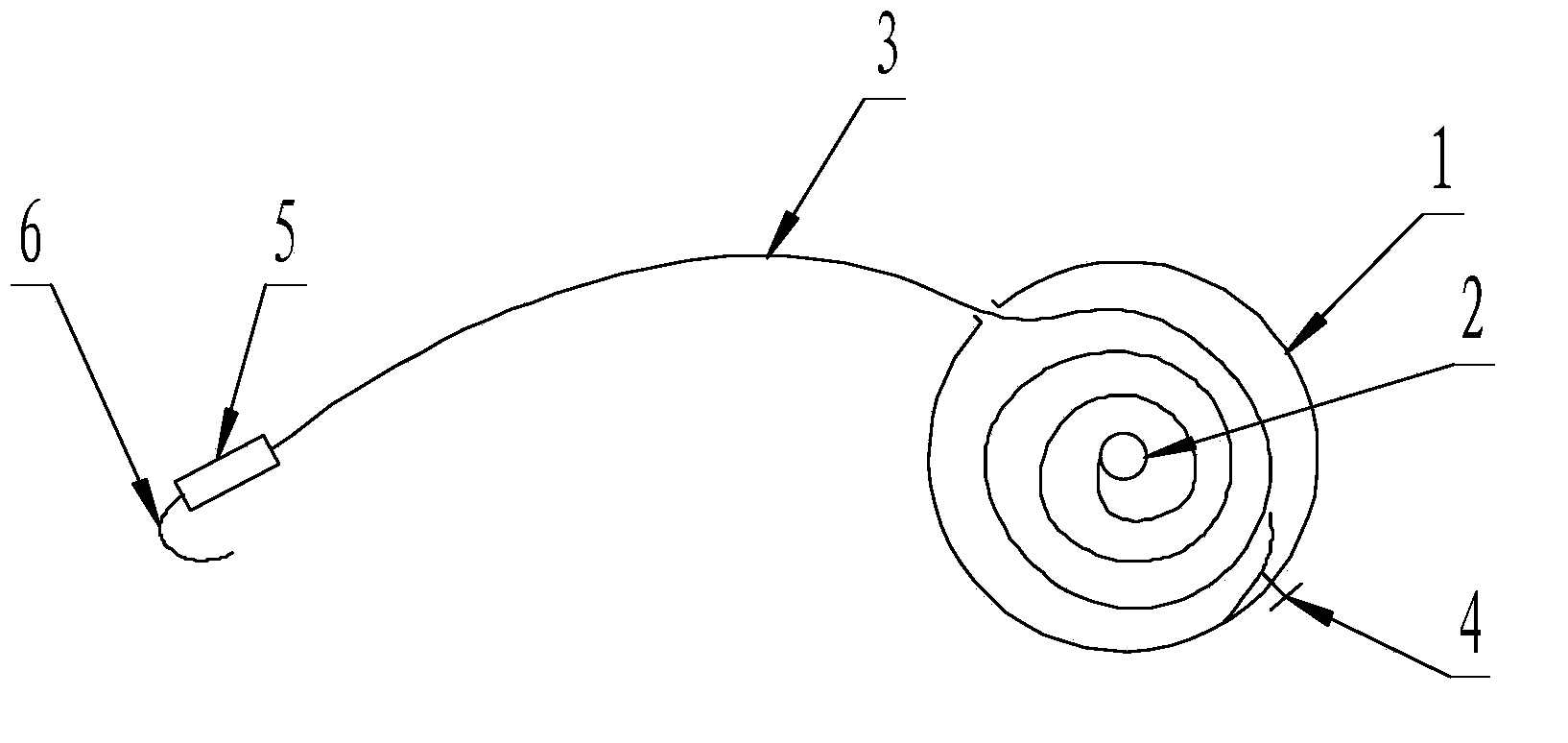

[0022] A spring device 2 is installed in the middle of the storage box 1, and the outer periphery of the spring device 2 is wound with a water-retaining steel sheet 3. One end of the water-retaining steel sheet 3 is connected to the magnetic block 5 through the outlet of the storage box 1, and a hook 6 is installed at one end of the magnetic block 5. The storage box 1 The locking device 4 is installed on the side and the water retaining steel sheet 3 correspondingly.

Embodiment 2

[0024] A plurality of sets of permeable holes are processed on the storage box 1, and each set of permeable holes is at least 8.

Embodiment 3

[0026] Storage box 1 is made of plastic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com