A method of using a water retaining device for a grinding machine

A technology of water blocking device and grinding machine, applied in grinding/polishing safety device, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of splashing and influence of grinding fluid, increase work output and reduce production cost , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

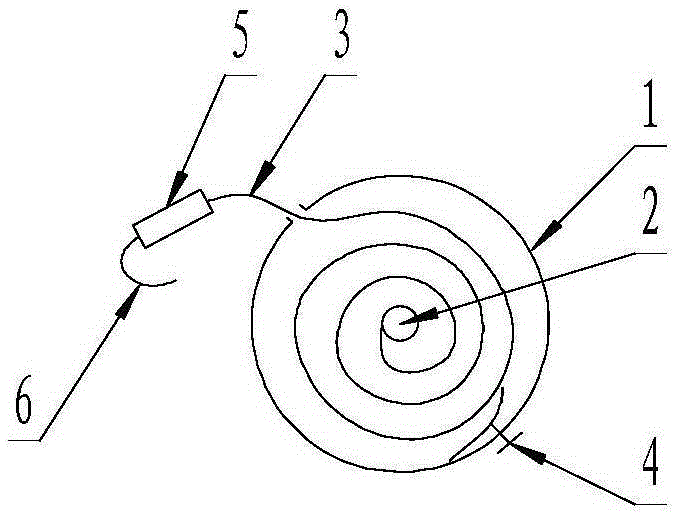

[0016] Pull the water-retaining steel sheet 3 out of the storage box 1, hang the hook 6 on the corresponding part of the outer circumference of the grinding wheel of the grinder, the magnetic block 5 is adsorbed on the corresponding part above the grinder hook 6, and push the locking device 4 and the water-retaining device in the storage box 1 The steel sheet 3 is compressed so that the water-retaining steel sheet 3 extending out of the storage box 1 is closely attached to the outer periphery of the grinding wheel.

Embodiment 2

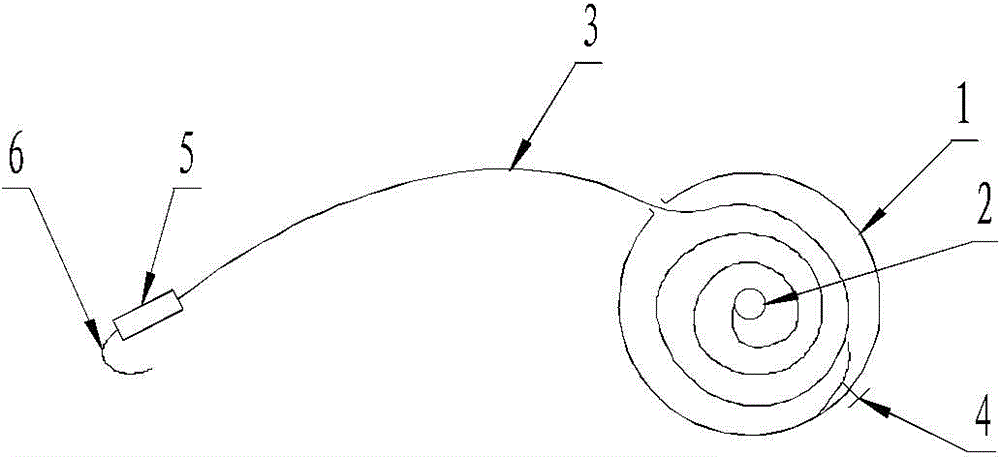

[0018] After use, separate the hook 6 and the water-retaining steel sheet 3 from the grinder, push the locking device 4 to disengage from the water-retaining steel sheet 3 in the storage box 1, and the water-retaining steel sheet 3 is automatically collected under the elastic force of the spring device 2 Inside storage box 1.

Embodiment 3

[0020] The moisture on the water-retaining steel sheet 3 seeps out from the permeable hole on the storage box 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com