Automatic tracking material grasping mechanical hand device

A technology of automatic tracking and manipulators, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of large space occupation and increased production line costs, and achieve the effects of improving adaptability, reducing costs, and overcoming multiple sets of grabbing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

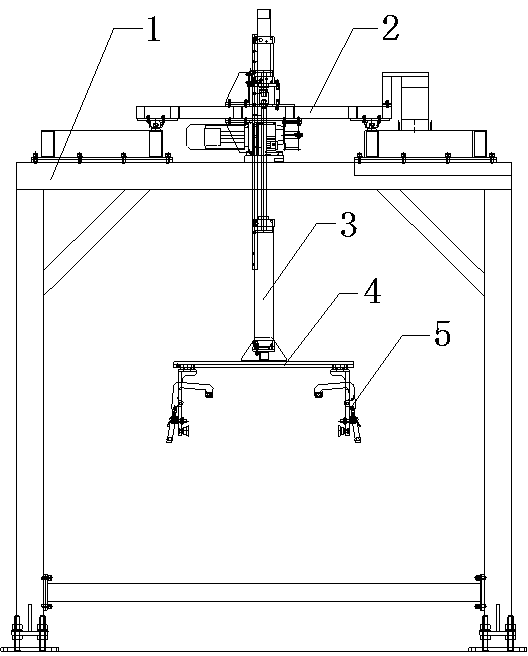

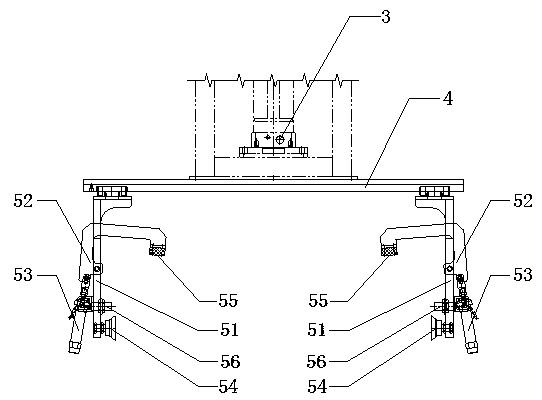

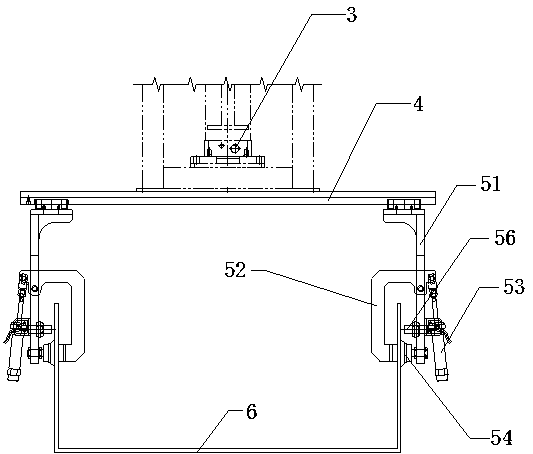

[0023] like Figure 1-5 As shown, an automatic tracking and grasping manipulator device includes a frame 1, a translation assembly 2 that moves horizontally and connects to the frame 1, a lift assembly 3 that moves up and down to connect the translation assembly 2, and a grasping assembly that connects the lift assembly 3. The assembly includes a mounting plate 4 and two sets of manipulators 5 arranged on the mounting plate 4. The two sets of manipulators 5 are arranged side by side, and the number of each set of manipulators 5 is two. The manipulators 5 in the same group are respectively located on both sides of the mounting plate 4. And relative setting, manipulator 5 moves and connects mounting plate 4, is provided with slide rail 41 on mounting plate 4, and manipulator 5 slides and connects slide rail 41, utilizes cylinder 42 to drive manipulator 5 to move back and forth on slide rail 41 simultaneously.

[0024] The translation assembly 2 is arranged on the top of the fram...

Embodiment 2

[0029] The rest are the same as the above-mentioned embodiments, the difference is that the manipulators 5 on the mounting plate 4 are one group, or other multiple groups, or grab two or more products at the same time, without limitation, depending on the specific production conditions .

[0030] Through the above technical solution, the beneficial effect of the technical solution of the present invention is: the setting of the translation component and the lifting component enables the grabbing component to automatically place the product to the designated position after grabbing the product; the grabbing component includes a mounting plate and is set on the installation There are at least one set of manipulators on the board, and the number of each set of manipulators is two. The manipulators in the same group are located on both sides of the mounting plate and are set opposite to each other. The manipulators move to connect the mounting plate so that the product is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com