Method for using bamboo fiber screening machine

A technology of bamboo fiber and screening machine, which is applied to wood processing utensils, manufacturing tools, etc., can solve problems such as low production efficiency, and achieve the effects of increasing work output, using safety, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

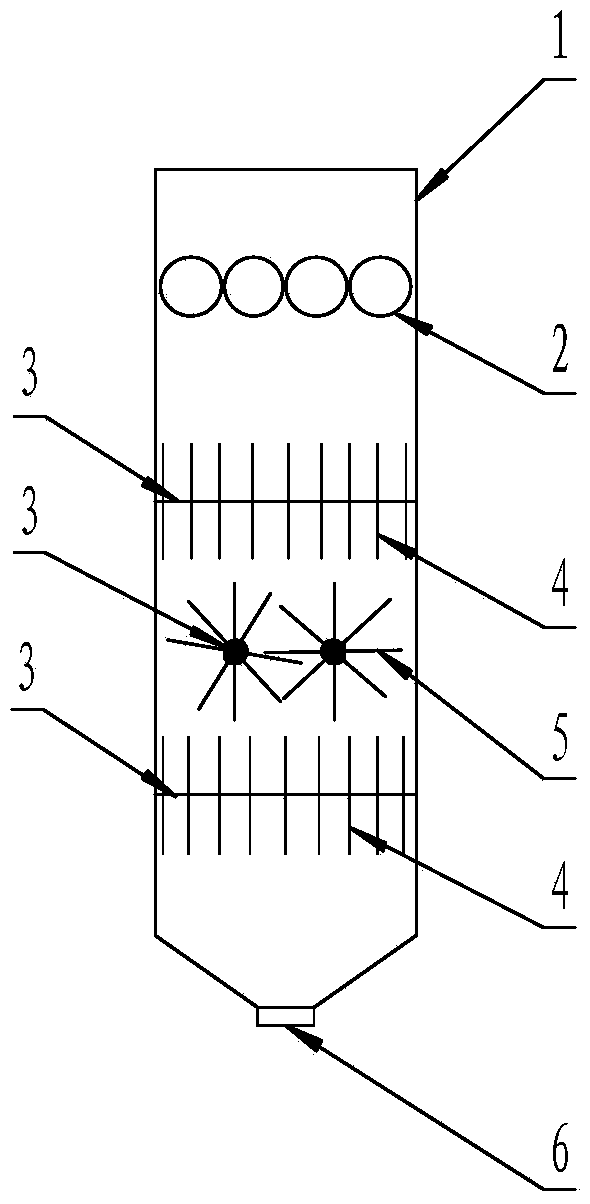

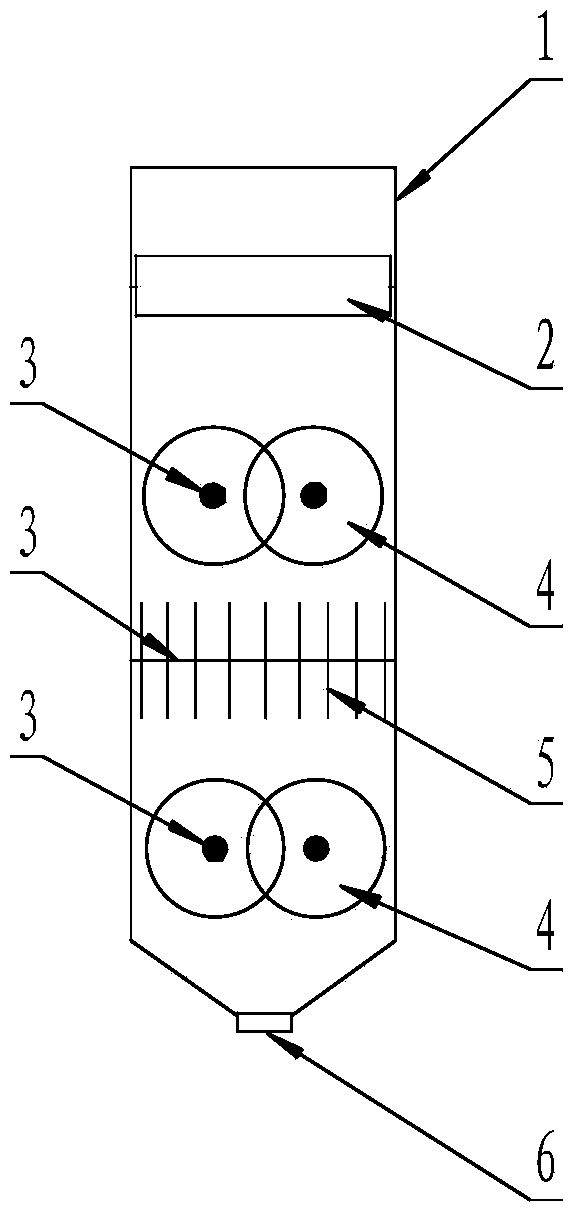

[0023] Fresh bamboo is processed into bamboo slices by slicing equipment, then enters the bamboo fiber screening machine, and after passing through the pressing roller device, it becomes a silky bamboo cake. After entering the primary cutting device, the intersecting circles on the adjacent two cutting devices Shaped cutting blade 4 cuts the silky bamboo cake into bamboo filaments, and the bamboo filaments enter the pull-off device, and the pull-off steel forks 5 that intersect each other on the adjacent two pull-off devices pull off the mixed bamboo filaments, and the separated bamboo filaments The bamboo silk enters the secondary cutting device, and the circular cutting blades 4 intersecting each other on two adjacent cutting devices cut the bamboo silk into bamboo fibers.

Embodiment 2

[0025] The diameter of the processed bamboo fiber is 0.2-1.2mm.

Embodiment 3

[0027] According to the processing standard, the distance between the circular cutting blade 4 on the primary cutting device and the secondary cutting device is adjusted; the distance between the steel forks 5 on the separating device is adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com