A pouring mold for the feed port of a biogas digester

A technology for pouring molds and biogas digesters, which is applied in the field of pouring molds at the feed port of biogas digesters, and can solve the problems of leakage, long construction period, and various types of consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

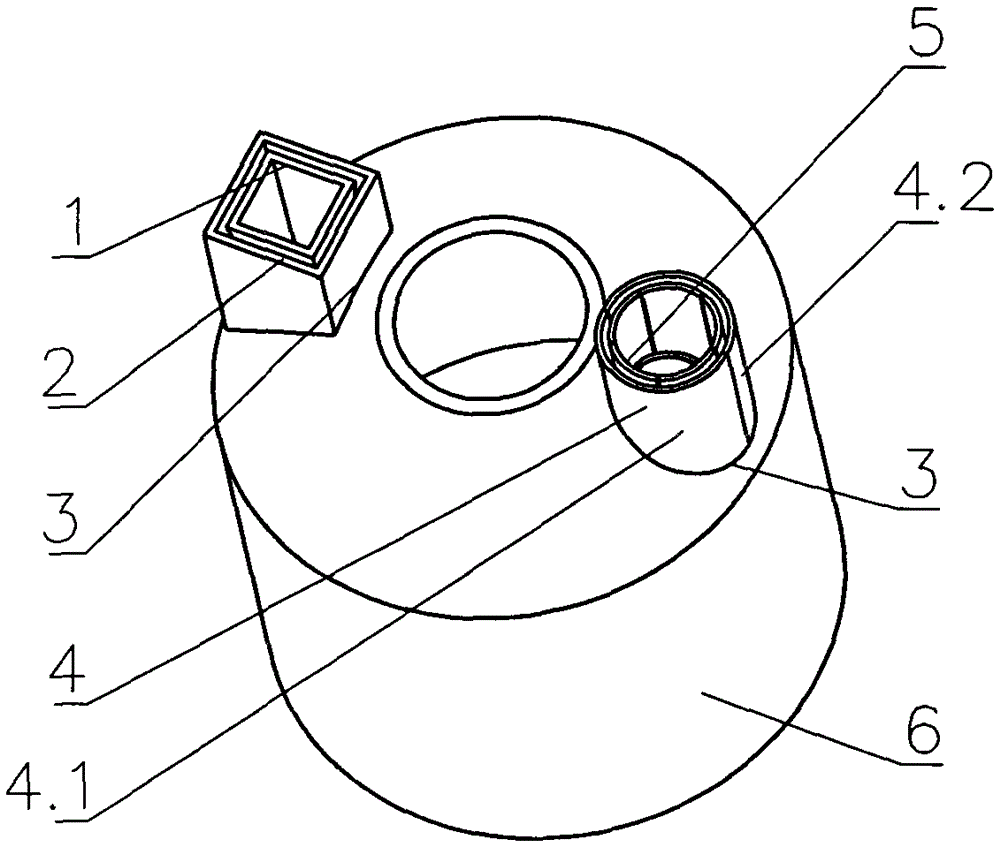

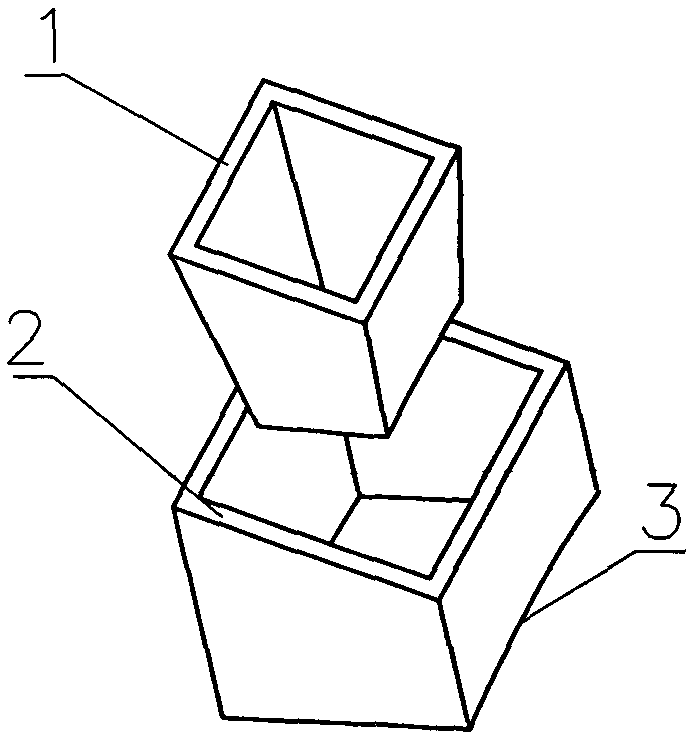

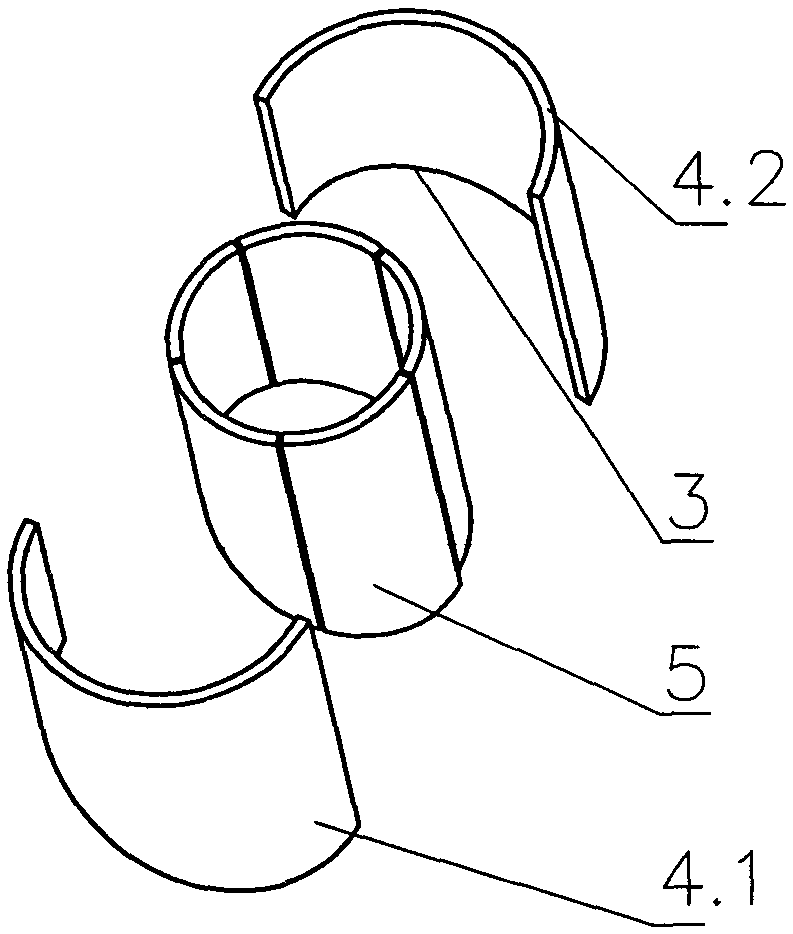

[0014] in figure 1 , figure 2 and image 3 In the shown pouring mold for the inlet of the biogas digester, a set of inlet molds including the inner mold 1 for the inlet and the outer mold 2 for the inlet and a set of inner molds containing the outlet are respectively provided on the top cover of the biogas digester body 7 5 and the discharge port mold body of the discharge port outer mold 4. The material of the inner mold 1, the outer mold of the inlet 2, the inner mold of the outlet 5, and the outer mold of the outlet 4 are all steel plates. The mold material is made of steel plates, which has the advantages of high strength and durability. In the construction, the inlet mold and the outlet mold can be used to directly pour the inlet and the outlet with concrete, eliminating the use of bricks in the original construction of the inlet and outlet , Reducing the types of building materials, correspondingly avoiding the trouble of purchasing and transporting bricks, and achievin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com