Engine suspension cushion

An engine mount and cushion technology, which is used in power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of reduced strength of engine mount cushions, affecting reliability, poor decoupling effect, etc., to meet NVH requirements. Performance requirements, reduced vehicle weight, and the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with accompanying drawing, the present invention is described in further detail:

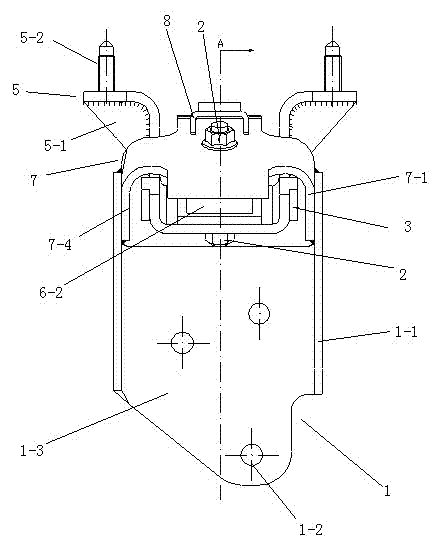

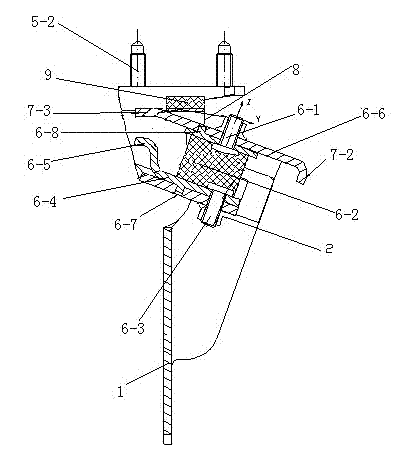

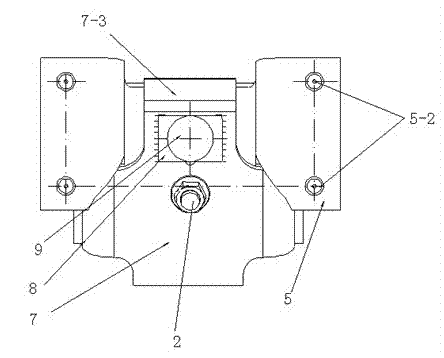

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 The shown engine suspension cushion comprises an upper frame 5, a lower frame 7, a shock-absorbing member 6 connected between the upper frame 5 and the lower frame 7, a small bracket 8 connected to the top of the lower frame 7, and a small bracket connected to the lower frame 7. The large bracket 1 on both sides of the lower part, the upper frame 5 is in the shape of a groove, the two sides of the mouth of the groove are respectively the first flange 5-3, and the two first flanges 5-3 are respectively provided with two vertically connected flanges. There is a first stud 5-2, and there is a forward extension 5-4 at the bottom of the groove, and a stud hole and a positioning pin hole are provided on the extension 5-4; the lower frame 7 is an inverted "U" ” shape, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com