Device and method for improving steam generating rate of low-temperature waste heat recovery system for sulfuric acid

A low-temperature waste heat and recovery system technology, applied in chemical instruments and methods, sulfur compounds, sustainable manufacturing/processing, etc., can solve problems such as ineffective recovery of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

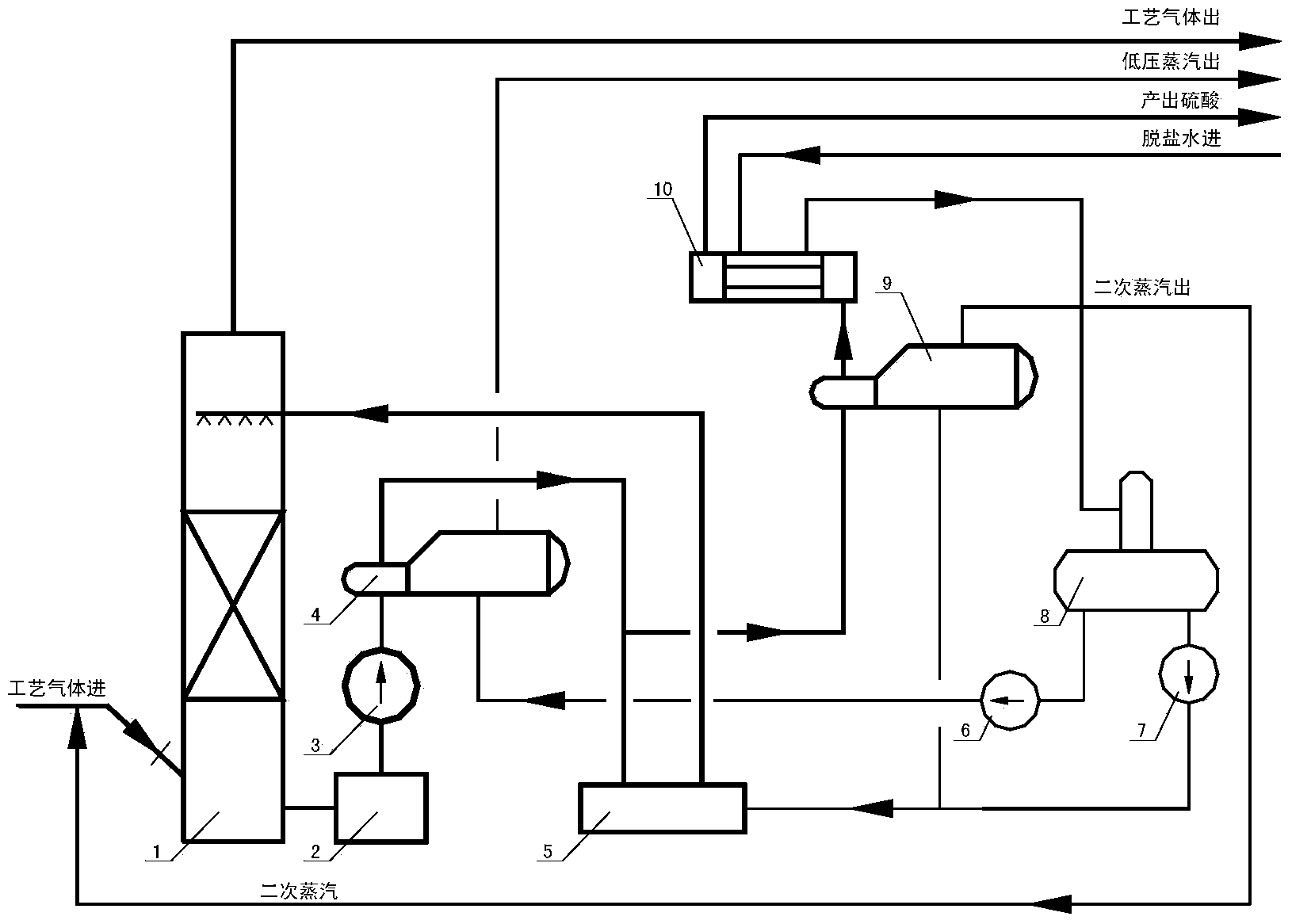

[0036] see figure 1 as shown,

[0037]The SO3-containing process gas is mixed with the secondary steam (with a pressure of 0.25±0.2MPa) produced by the second evaporator 9 at the entrance of the high-temperature absorption tower 1, and the SO3 in the process gas is absorbed by the circulating acid in the high-temperature absorption tower 1 to release heat Produce high-temperature concentrated sulfuric acid at 205±20°C. At this time, the low-grade heat in the secondary steam is converted into the heat of high-temperature concentrated sulfuric acid. The confluence of high-temperature concentrated sulfuric acid at the bottom of the tower enters the high-temperature circulation tank 2, and is sent to the high-temperature circulation pump 3 under pressure. Enter the evaporator 4 to generate (0.8±0.2MPa) low-pressure steam. After the concentrated sulfuric acid exits the evaporator 4, the acid temperature drops to 190±20°C to obtain the acid production of the system, and send a part ...

Embodiment 2

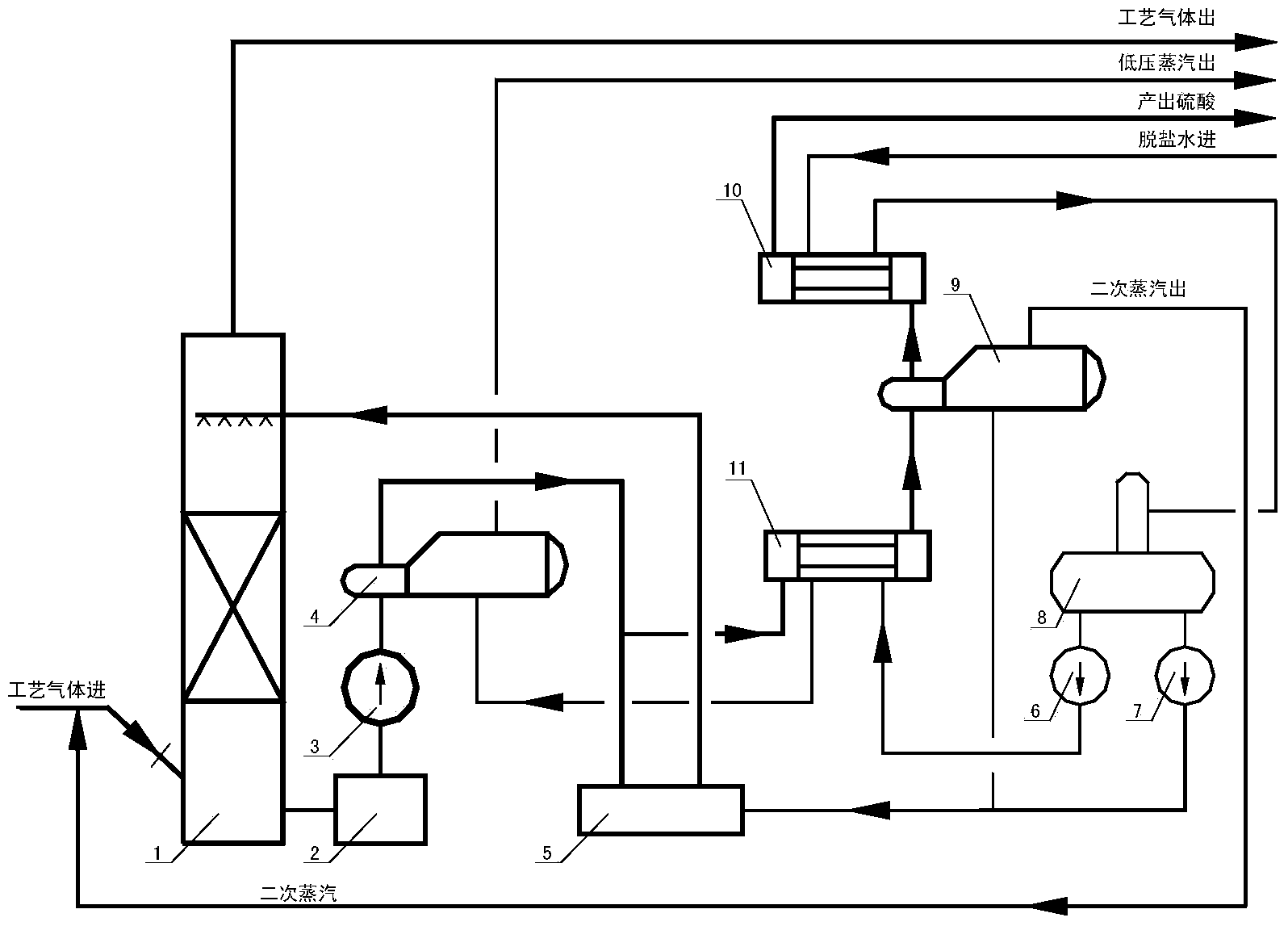

[0039] see figure 2 as shown,

[0040] The SO3-containing process gas is mixed with the secondary steam (with a pressure of 0.25±0.2MPa) produced by the second evaporator 9 at the entrance of the high-temperature absorption tower 1, and the SO3 in the process gas is absorbed by the circulating acid in the high-temperature absorption tower 1 to release heat Produce high-concentrated sulfuric acid at about 205±20°C. At this time, the low-grade heat in the secondary steam is converted into the heat of high-temperature concentrated acid. The confluence of high-temperature concentrated acid at the bottom of the tower enters the high-temperature circulation tank 2 and is pressurized by the high-temperature circulation pump 3. Send it to the evaporator 4 to generate (0.8±0.2MPa) low-pressure steam. After the concentrated sulfuric acid exits the evaporator, the acid temperature drops to 190±20°C to obtain the acid production of the system, and a part of the acid production of the sys...

Embodiment 3

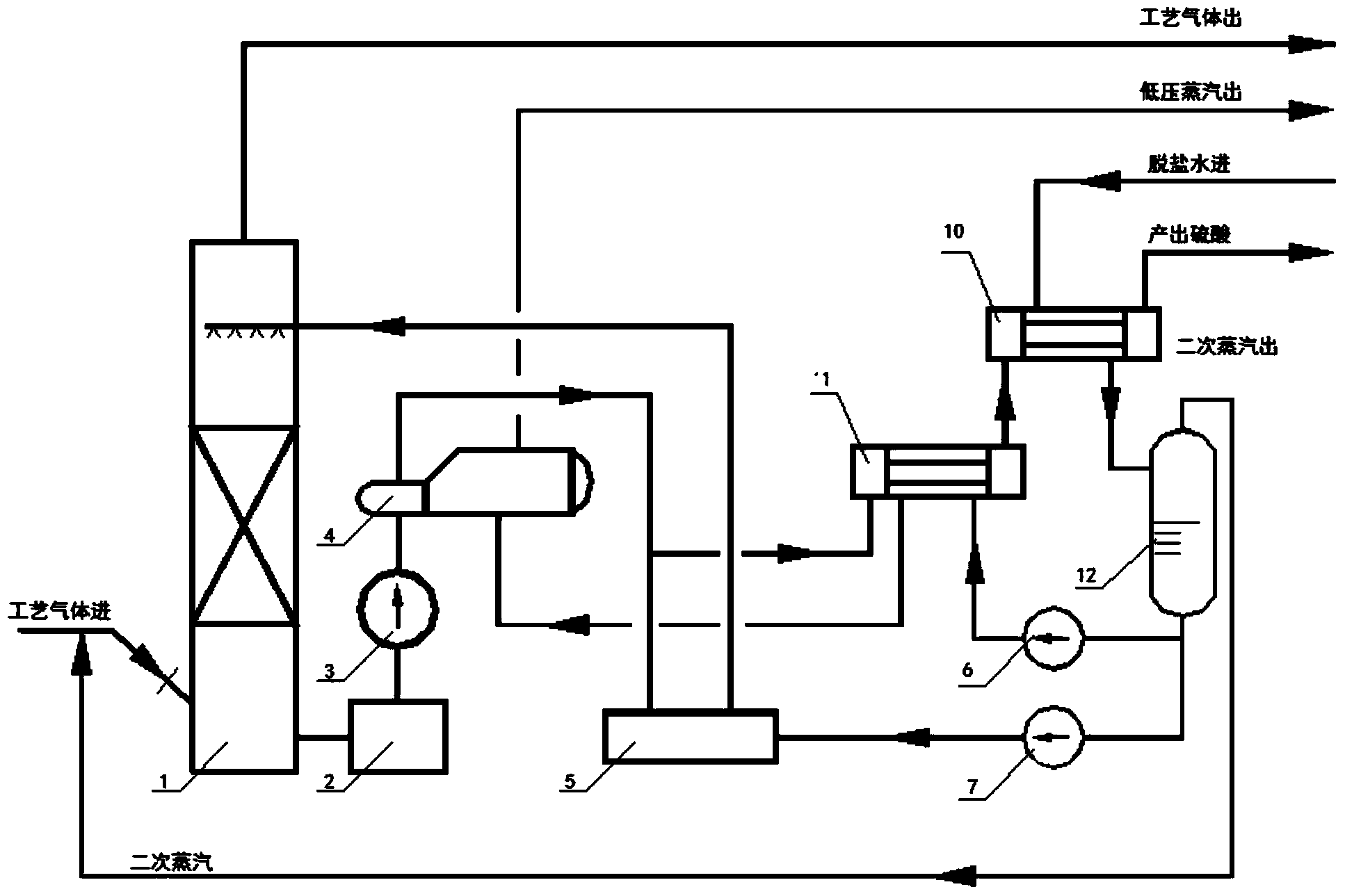

[0042] see image 3 as shown,

[0043] The SO3-containing process gas is mixed with the secondary steam (with a pressure of 0.25±0.2MPa) produced by the flash tank 12 at the inlet of the high-temperature absorption tower 1, and the SO3 in the process gas is absorbed by the circulating acid in the high-temperature absorption tower 1, releasing heat to generate High-concentrated sulfuric acid at about 205±20°C. At this time, the low-grade heat in the secondary steam is converted into the heat of high-temperature concentrated acid. The confluence of high-temperature concentrated acid at the bottom of the tower enters the high-temperature circulation tank 2, and is sent to the high-temperature circulation pump 3 under pressure. Enter the evaporator 4 to generate (0.8±0.2MPa) low-pressure steam, and after the concentrated sulfuric acid exits the evaporator, the acid temperature drops to 190±20°C to obtain the acid production of the system. A part of the acid production is sent to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap