High-temperature flue gas oxygen-doped type oxygen-enriched combustion steam-injection boiler

A high-temperature flue gas, oxygen-enriched combustion technology, applied in the combustion method, combustion equipment, combustion air/fuel supply, etc., can solve the problems of increased emissions, reduced flue gas volume, shortened burning time, etc. The effect of increasing the rate and reducing the emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

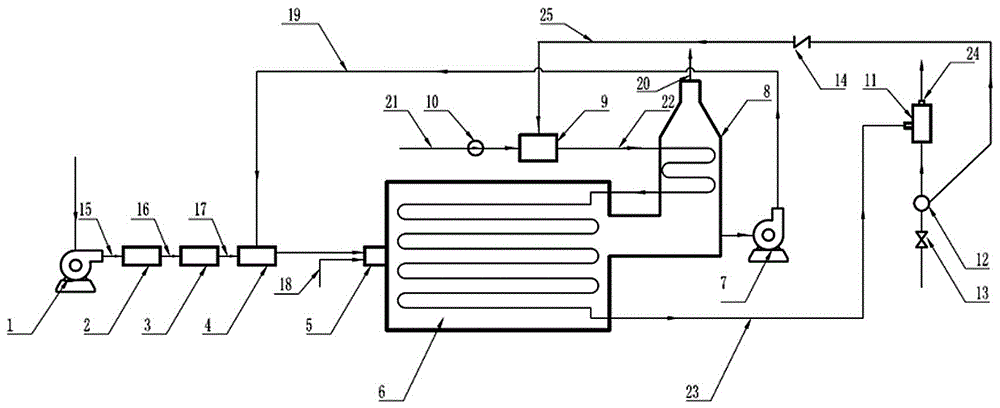

[0019] Such as figure 1 As shown, the high-temperature flue gas oxygen-mixed oxygen-enriched combustion steam injection boiler of the present invention includes an oxygen-enriched generating device, a combustion aid ratio and a preheating device, a furnace body, a radiation section, a convection section, a feed pump 10, a water mixer 9, Steam-water separator 11, header tank 12 and burner 5. The oxygen-enriched generating device is composed of a blower 1, a membrane-type oxygen-enriched generator 2, and a pure oxygen storage tank 3; The gas mixing tank is connected to the circulating fan through the flue gas circulation pipe; the radiation section 6 is set in the inner cavity of the furnace body; the convection section 8 is set outside the furnace body; the water mixer 9 is respectively connected with the feed water pump 10, the convection section 8 and the header box 12 The steam-water separator 11 communicates with the radiation section 6 and the header box 12 respectively, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap