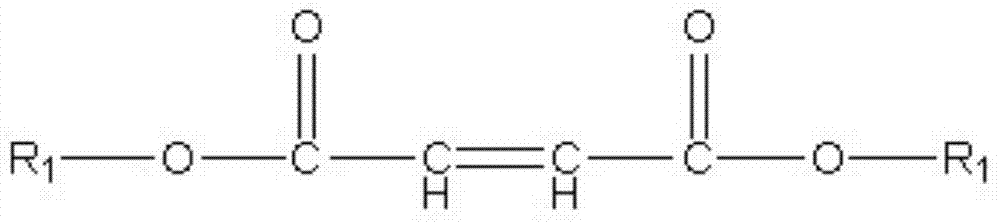

Polyethylene glycol methyl ether maleate, and preparation method and application thereof

A technology of polyethylene glycol monomethyl ether and maleic acid, which is applied in the field of concrete admixture synthesis, can solve the problems of cumbersome post-processing such as storage, recycling, and discharge, large equipment investment, and high risk, and it is easy to achieve reaction conditions The effect of control, less investment in equipment, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 50 g of polyethylene glycol monomethyl ether with a molecular weight of 1000 and 2.131 g of maleic anhydride into a three-necked flask, heat up to 60° C., melt, and add polymerization inhibitor p-benzoquinone 0.104 g, hydroquinone monomethyl ether 0.104 g, Hydroquinone 0.104g, catalyst p-toluenesulfonic acid 2.09g, after stirring evenly, pass nitrogen, react at 90 ° C for 2 hours, so that most of the reaction products form maleic acid monopolyethylene glycol monomethyl ether ester, and then heat up to 140 ℃, constant temperature stirring reaction for 7.5h, that is, bis(polyethylene glycol monomethyl ether) maleate is obtained. Denoted as MADMPEG-1.

Embodiment 2

[0036] 50g of the monomer polyethylene glycol monomethyl ether with a molecular weight of 350 and 4.245g of maleic anhydride were added to the three-necked flask, the temperature was raised to 60°C, melted, 1.08g of the polymerization inhibitor hydroquinone and 1.627g of the catalyst concentrated sulfuric acid were added, and the mixture was stirred. After homogeneous, pass nitrogen and react at 90 °C for 2 hours, so that most of the reaction products form maleic acid monopolyethylene glycol monomethyl ether ester, then heat up to 145 °C, and stir at constant temperature for 4 hours to obtain bis-polyethylene maleate. Glycol monomethyl ether ester, denoted as MADMPEG-2.

Embodiment 3

[0038] 50g of the monomer polyethylene glycol monomethyl ether with a molecular weight of 500 and 3.502g of maleic anhydride were added to the three-necked flask, the temperature was raised to 60°C, melted, and the polymerization inhibitor hydroquinone 0.54g, p-benzoquinone 0.53g, and a catalyst were added. 1.87g of p-toluenesulfonic acid, after stirring evenly, pass nitrogen, and react at 90 °C for 2 hours, so that most of the reaction products form maleic acid monopolyethylene glycol monomethyl ether ester, then the temperature is raised to 150 °C, and the reaction is stirred at a constant temperature for 5 hours. That is, bis-polyethylene glycol monomethyl ether maleate is obtained, which is designated as MADMPEG-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com