Low temperature treatment-vibration aging combined residual stress homogenization method

A residual stress and vibration aging technology, applied in the field of residual stress homogenization of metal workpieces or blanks, and cold vibration composite residual stress homogenization, can solve the problem of limited effect, and achieve the effect of reducing the cost of thermal action and shortening the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

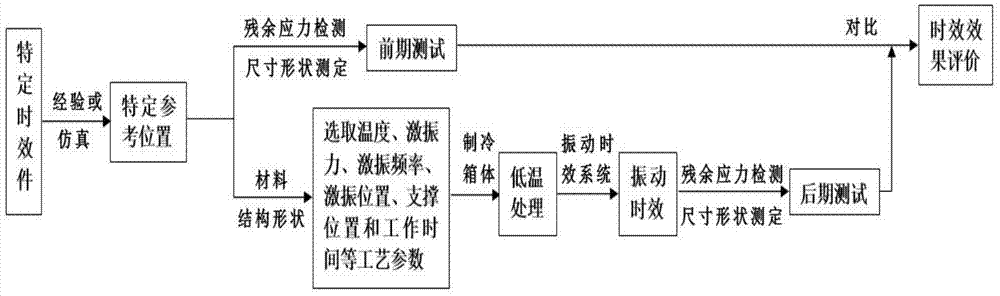

[0034] See figure 1 , a method for homogenizing cold vibration composite residual stress described in the present invention, the specific steps of the method are as follows:

[0035] Step 1: According to the residual stress test experience in production practice or combined with computer numerical simulation technology, analyze the residual stress distribution law of aging parts, and select the specific reference position of aging parts;

[0036] Step 2: In order to evaluate the effect of residual stress homogenization, for the specific reference position of the aging parts selected in step 1, carry out the residual stress test and the size and shape measurement before the cold-vibration composite aging;

[0037] Step 3: Analyze the material and structural shape of aging parts, formulate relevant process flow, and select process parameters such as low temperature, excitation force, excitation frequency, excitation position, support position and working time;

[0038] Step 4: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com