Modularized lifting transverse-moving type parking equipment

A technology of lifting and moving type and parking equipment, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of prolonging the product cycle, a large amount of cost, and the structure cannot be disassembled and assembled, and achieve the mechanical properties of the overall structure. Good, low construction period, convenient handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

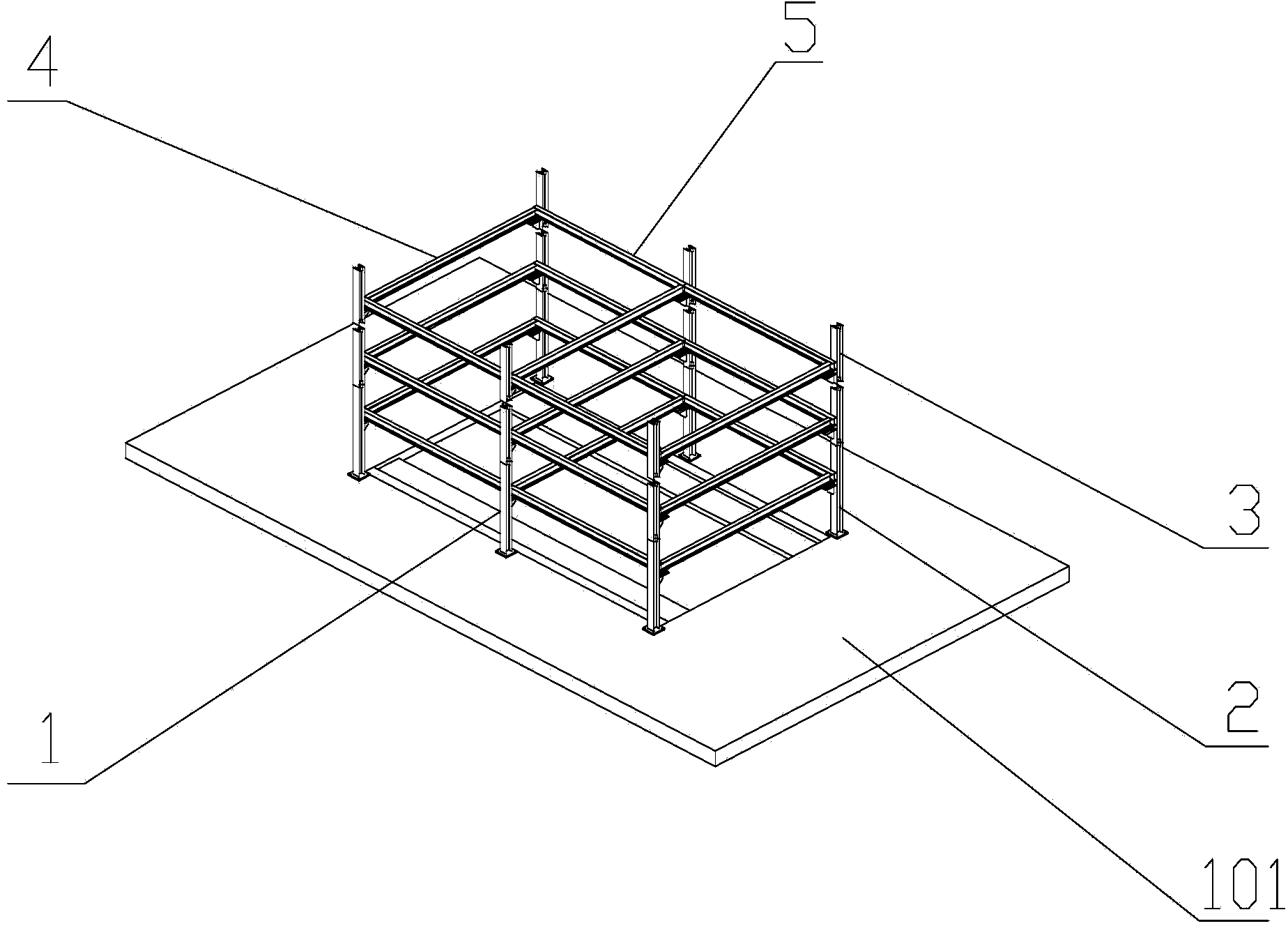

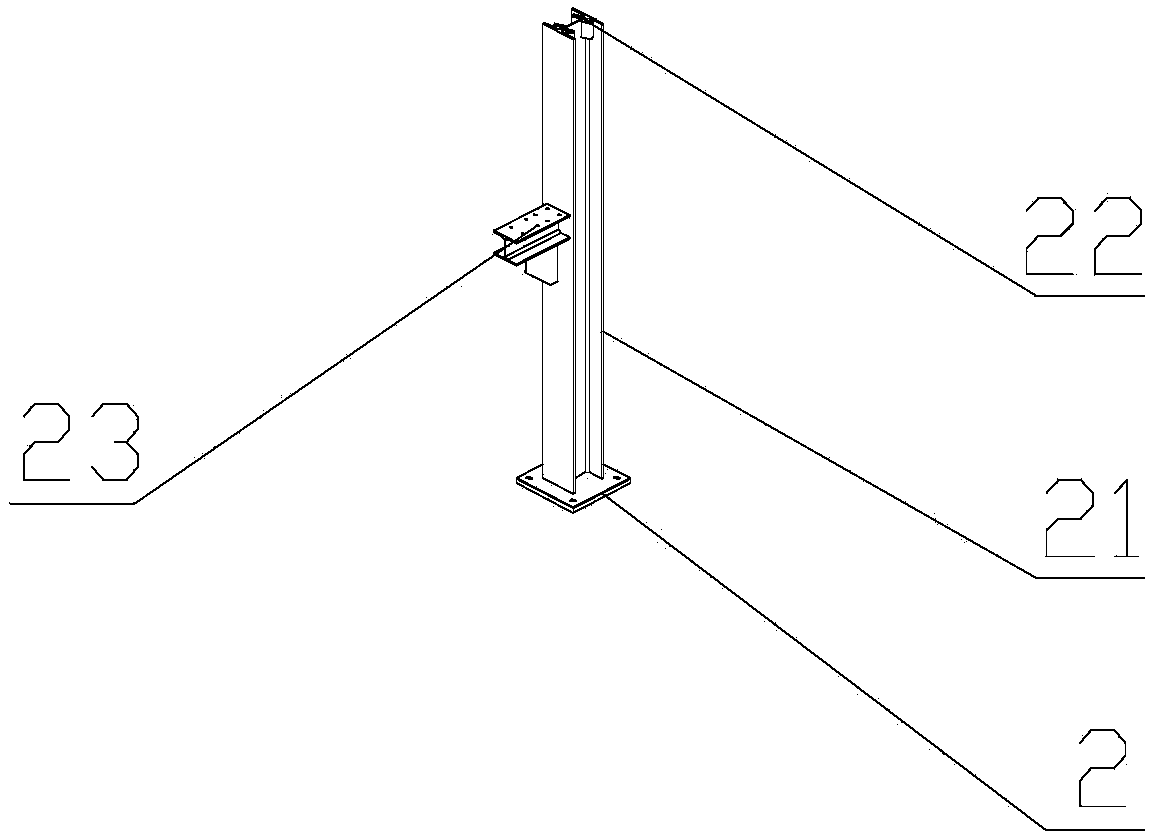

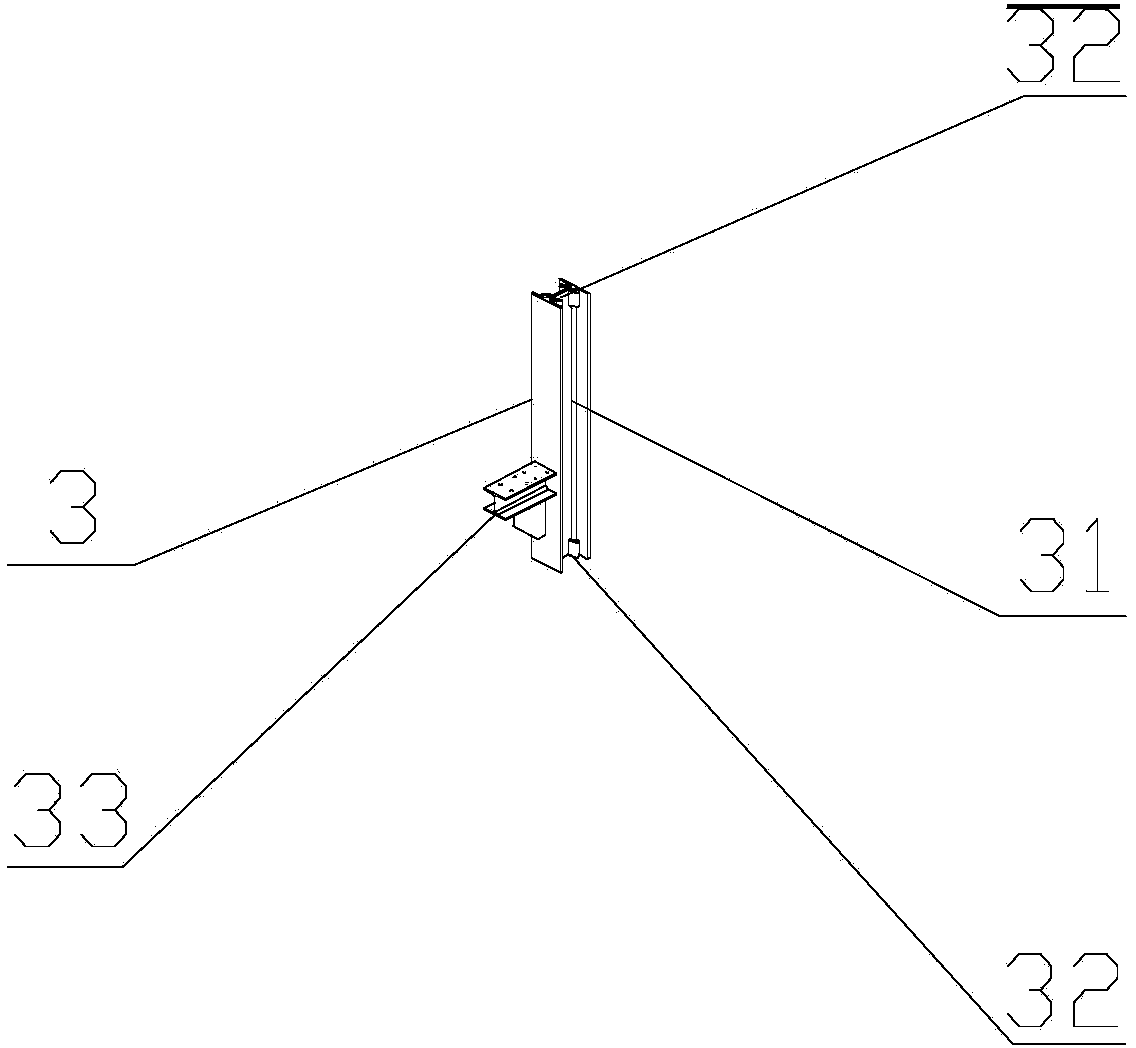

[0030] Such as Figure 1 to Figure 8 Shown, a kind of parking equipment of modular lift and traverse type, comprises frame structure 1, and frame structure 1 has several layers of car-carrying spaces, and the bottom of each layer of car-carrying spaces is provided with car-carrying plate 7, and the second layer and its second The car-loading space above the floor is provided with a lifting device for lifting the car-carrying plate 7. The vehicle-carrying space on the first floor of the frame structure 1 is composed of beams 4, longitudinal beams 5 and foundation section columns 2. Column 2, all beams 4, longitudinal beams 5 and foundation section columns 2 together form a first-floor car-carrying space in the shape of a cuboid as a whole, and the rod body A21 of the foundation section column 2 is provided with a connection seat A23 for beams and longitudinal beams , The beam 4 and the longitudinal beam 5 are detachably mounted on the connecting seat A23 of the beam and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com