High-strength electromagnetic pulse protection structure material

An electromagnetic protection and electromagnetic pulse technology, which is applied in the direction of electrical components, lamination, antennas, etc., can solve the problems that the electrical performance index is difficult to meet the actual application requirements, the electrical performance is quite different from the design value, and the mechanical and electrical properties are poor. Achieve the effect of improving the mechanical properties of the material structure, improving the mechanical properties, and increasing the molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-strength electromagnetic pulse protection structure material, the preparation steps are as follows:

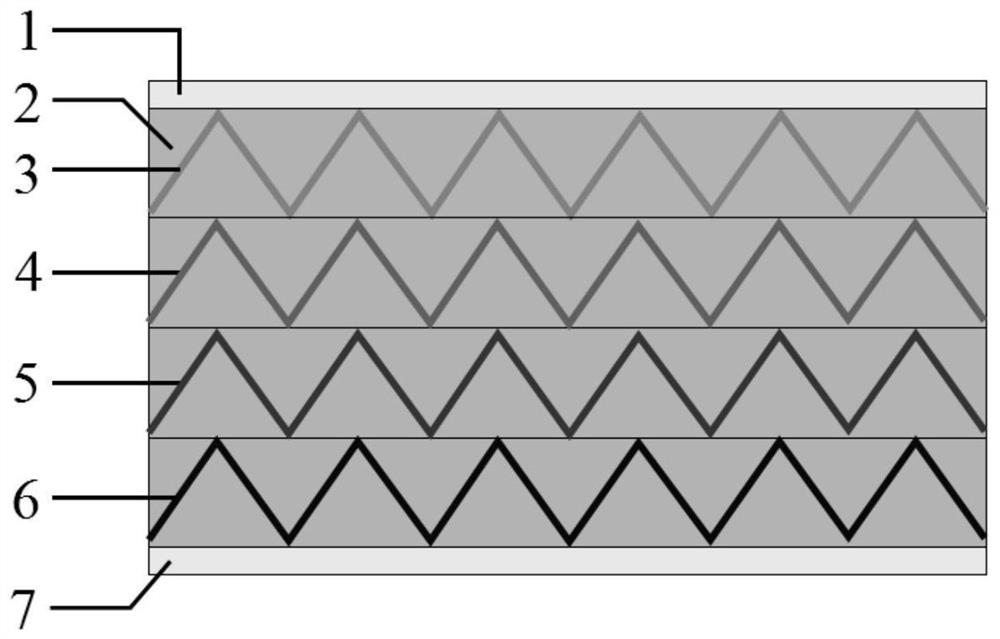

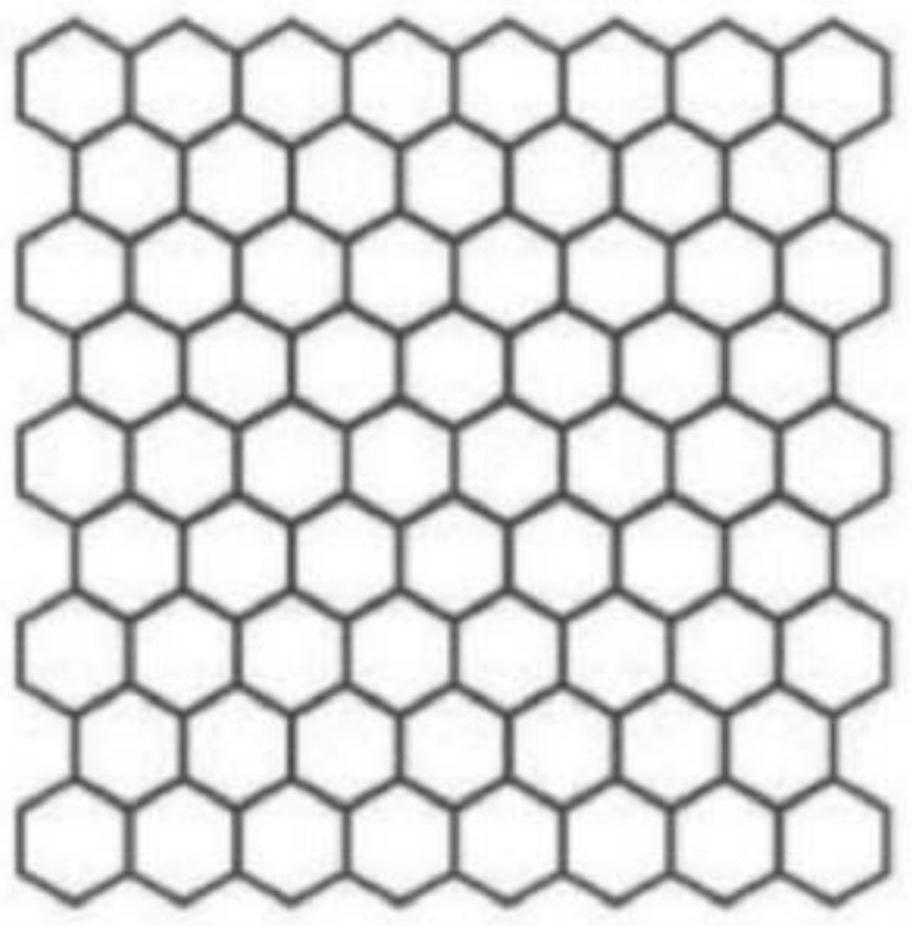

[0034] 1) In 4 pieces of polycarbonate lattice structure materials (obtained by the structure units with a side length of 2.5mm, a thickness of 5mm, and tip protrusions in a honeycomb lattice distribution, the planar structure schematic diagram is as follows figure 2 As shown, the size is 300mm×300mm×21mm) the surface is impregnated with acetylene carbon black coating material (obtained by mixing acetylene carbon black with an average particle size of 10 μm into epoxy resin, room temperature curing agent is added to epoxy resin, and acetylene carbon black coating The mass percentage of acetylene carbon black in the material is 20%) and cured at room temperature to obtain 4 lattice structure electromagnetic protection layers, and the quality of the acetylene carbon black coating in the 4 lattice structure electromagnetic protection layers is made 100% by adjusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com