Artificial shoulder joint prosthesis

A shoulder joint and prosthesis technology, applied in the field of human shoulder joint replacement, can solve the problems of multi-level porous material properties such as uneven mechanical strength and elastic modulus, failure to meet the functional requirements of bionic artificial bones, and insufficient uniformity, etc., to achieve convenience The effect of fixing the product position, good structural mechanical properties, and reducing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

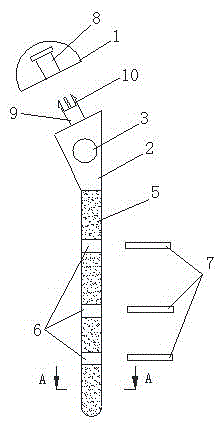

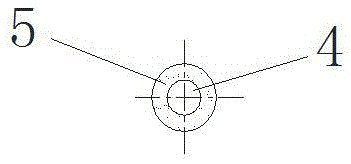

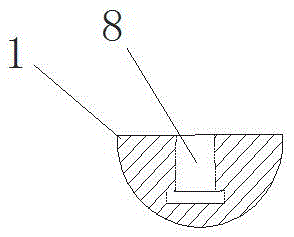

[0029] As attached to the manual Figure 1-3Shown, a kind of artificial shoulder joint prosthesis, it comprises humerus head 1 and humerus stem 2; Its humerus stem 2 upper part is provided with round hole 3, and its lower handle body is by body 4, and is located at the wrapping of body 4 outer layers The cladding layer 5 is composed of a cladding layer 5, wherein the cladding layer 5 is made of a multi-level porous material; a plurality of through holes 6 are uniformly distributed on the handle body, and nails 7 are matched in the through holes 6; the humeral head 1 is provided with Installation groove 8, and the diameter of installation groove 8 bottom is greater than the diameter of upper part; The upper end face of its humerus handle 2 is connected with fixed rod 9; Clip 10; the fixed rod 9 is inserted into the installation groove 8, the elastic clip 10 on the upper end of the fixed rod 9 fits in the lower part of the installation groove 8, and the barb hook on the elastic ...

Embodiment 2

[0040] As attached to the manual Figure 4 Shown, a kind of artificial shoulder joint prosthesis, it comprises humerus head 1 and humerus stem 2; Its humerus stem 2 upper part is provided with round hole 3, and its lower handle body is by body, and is located at the cladding layer of body outer layer 5 components, wherein, the cladding layer 5 is made of multi-level porous material; a plurality of through holes 6 are evenly distributed on the handle body; a mounting groove 8 is provided inside the humeral head 1, and the diameter of the lower part of the mounting groove 8 is larger than that of the upper part diameter; the upper end surface of the humerus stem 2 is connected with a fixed rod 9; the upper end of the fixed rod 9 is provided with two symmetrically distributed elastic clips 10 with barbs; the fixed rod 9 is inserted into the installation groove 8, The elastic clip 10 on the upper end of the fixed rod 9 fits in the lower part of the installation groove 8, and the b...

Embodiment 3

[0052] As attached to the manual Figure 5 Shown, a kind of artificial shoulder joint prosthesis, it comprises humerus head 1, humerus stem 2 and buffer pad 11; Its humerus stem 2 upper part is provided with round hole 3, and its lower handle body is by body, and is located at body outer layer The cladding layer 5 is composed of a cladding layer 5, wherein the cladding layer 5 is made of a multi-level hole material; a plurality of through holes 6 are evenly distributed on the handle body, and nails 7 are matched in the through holes 6; the inside of the humeral head 1 An installation groove 8 is provided, and the diameter of the lower part of the installation groove 8 is greater than that of the upper part; the upper end surface of the humerus handle 2 is connected with a fixed rod 9; The elastic clip 10; its fixed rod 9 passes through the buffer pad 11 and is inserted into the installation groove 8, the elastic clip 10 on the upper end of the fixed rod 9 fits in the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com