a shoulder prosthesis

A shoulder joint and prosthesis technology, applied in the field of human shoulder joint replacement, can solve problems such as uneven distribution of elastic modulus, insufficient uniformity, and decline in structural mechanical strength, achieve good structural mechanical properties, improve connection stability, and ensure Uniform and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

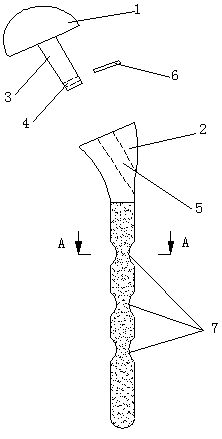

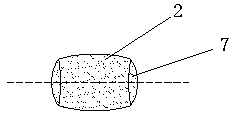

[0025] As attached to the manual Figure 1-2 As shown, a shoulder joint prosthesis includes a humeral head 1 and a humeral stem 2; its humeral head 1 is a hemispherical body, and an insertion rod 3 is fixed on its end surface; The perforation 4 distributed in the direction of the axis of the insertion rod 3; the head of the humerus stem 2 is provided with an oblique insertion hole 5; the insertion rod 3 is inserted into the insertion hole 5, and the insertion rod 3 is provided with a perforation 4 protrudes from the insertion hole 5; a nail 6 is fitted in the perforation 4, and the length of the nail 6 is greater than the length of the perforation 4; the handle body of the humerus stem 2 is made of a multi-stage hole material, and is realized by laser welding The head of the humerus handle 2 is fixedly connected, and the handle body is provided with six symmetrically distributed arc-shaped grooves 7; the multi-stage porous material used in this embodiment is porous titanium wi...

Embodiment 2

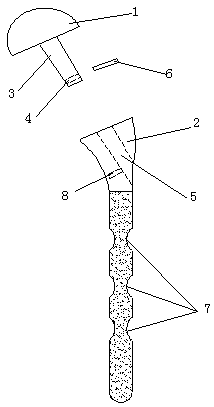

[0037] As attached to the manual image 3 As shown, a shoulder joint prosthesis includes a humeral head 1 and a humeral stem 2; its humeral head 1 is a hemispherical body, and an insertion rod 3 is fixed on its end surface; The perforation 4 distributed in the axial direction of the insertion rod 3; the head of the humerus stem 2 is provided with an insertion hole 5 penetrating obliquely, and a mounting hole 8 vertically connected with the insertion hole 5; the insertion rod 3 is inserted into the insertion hole 5. In the connection hole 5, and the insertion rod 3 is provided with the position of the perforation 4 to stretch out the insertion hole 5; the perforation 4 is equipped with a nail 6, the length of the nail 6 is greater than the length of the perforation 4, and the nail 6 is simultaneously connected with the perforation 4 and the perforation 4. The mounting hole 8 is fixed in cooperation; the handle body of the humerus stem 2 is made of multi-level hole material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com