Pillar pre-segregation segmental strip filling mining method and the ore body applicable to this mining method

A technology of strip filling and mining method, which is applied in the field of pillar pre-isolation and segmented strip filling mining method, which can solve the problems of high cost of filling mining method, impact on sustainable development, and ground surface does not allow subsidence, etc., so as to avoid a large amount of resources Loss, reduction of filling costs, effects of preventing deformation and subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Take the mining method of the Dazhuohe Iron Mine Area of Shandong Shengda Mining Co., Ltd. as an example to specifically illustrate the ore pillar pre-isolation segmentation block filling mining method of the present invention:

[0020] The Dazhuohe Iron Mine Area of Shandong Shengda Mining Co., Ltd. is located about 1km west of Dazhuohe Village, Tushan Town, Laizhou City, at the junction of Yantai City and Qingdao City. The strike length of the ore body is 2100m, the inclination angle is 0°~20°, and the thickness varies greatly. The maximum thickness is 77.74m, the minimum thickness is 2.98m, and the general thickness is 10~30m. Dazhuohe Iron Mine has 44.939 million tons of iron ore resource reserves, with an average grade of TFe28.97%. It is mined by pillar pre-isolation, segmented and block filling mining method. The specific implementation methods are as follows:

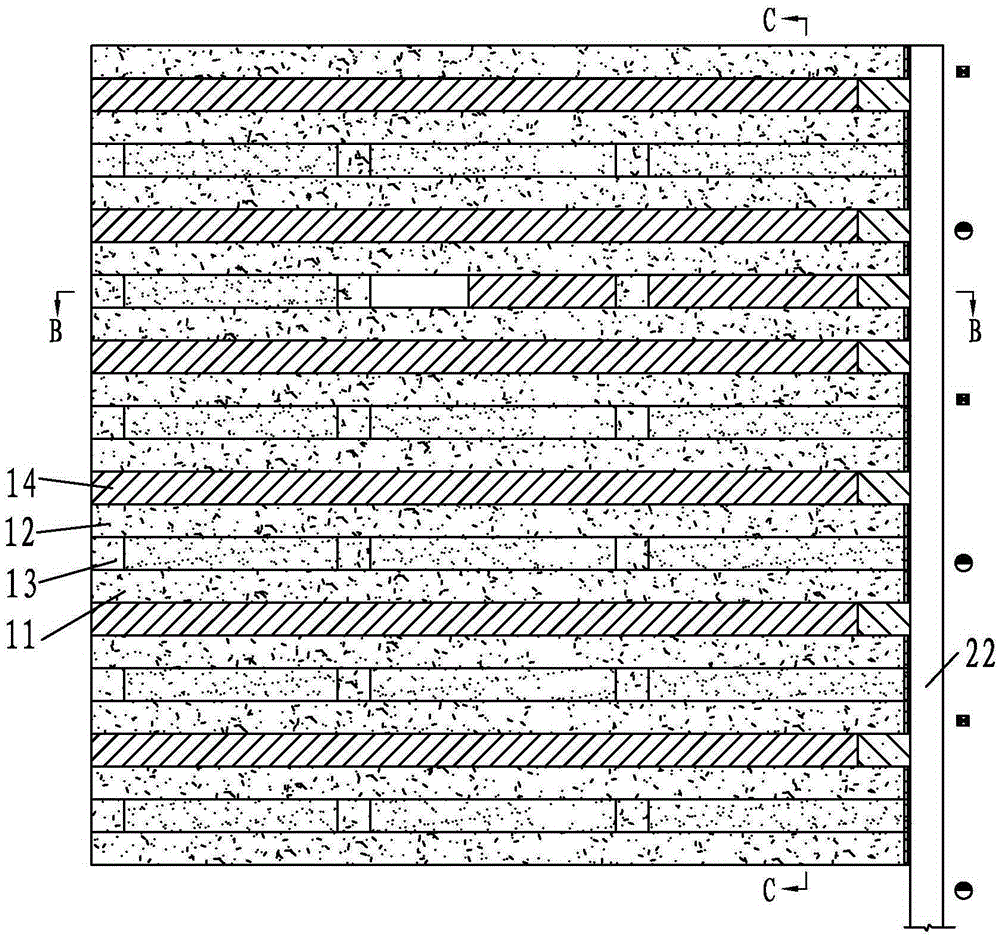

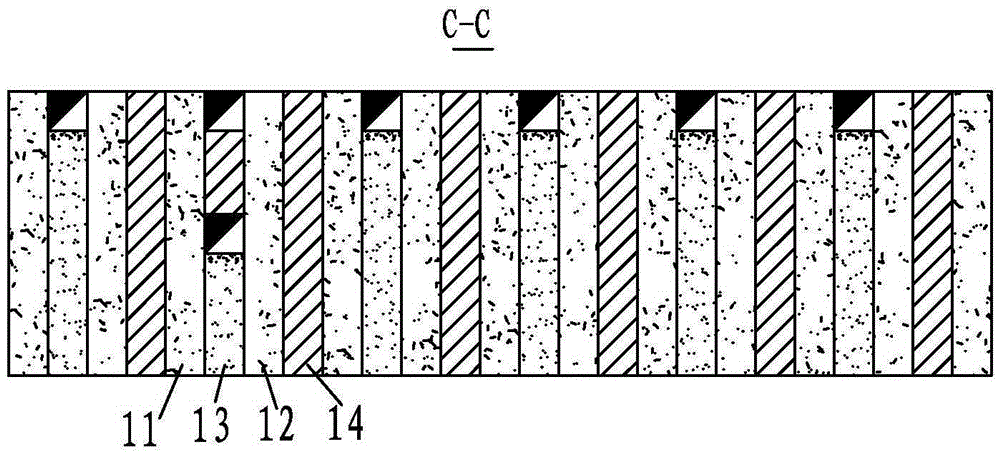

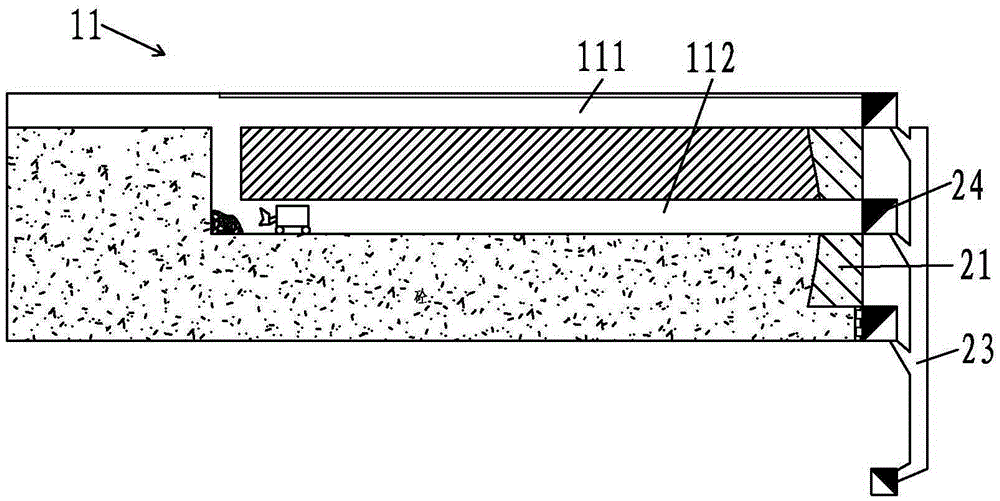

[0021] (1) Divide the entire mining area into multiple areas, such as figure 1 , 4 As shown, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com