A long-distance armless rake mine trolley

A long-distance, mining platform technology, applied in the direction of motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of unsatisfactory results, large auxiliary workload, poor operation safety, etc., and reduce stopes. The effect of reducing mining time, production cost, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

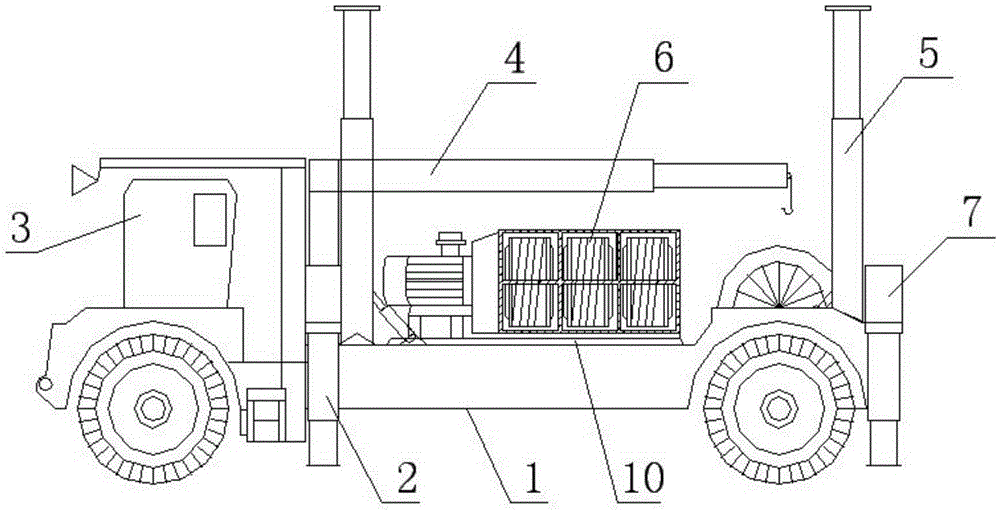

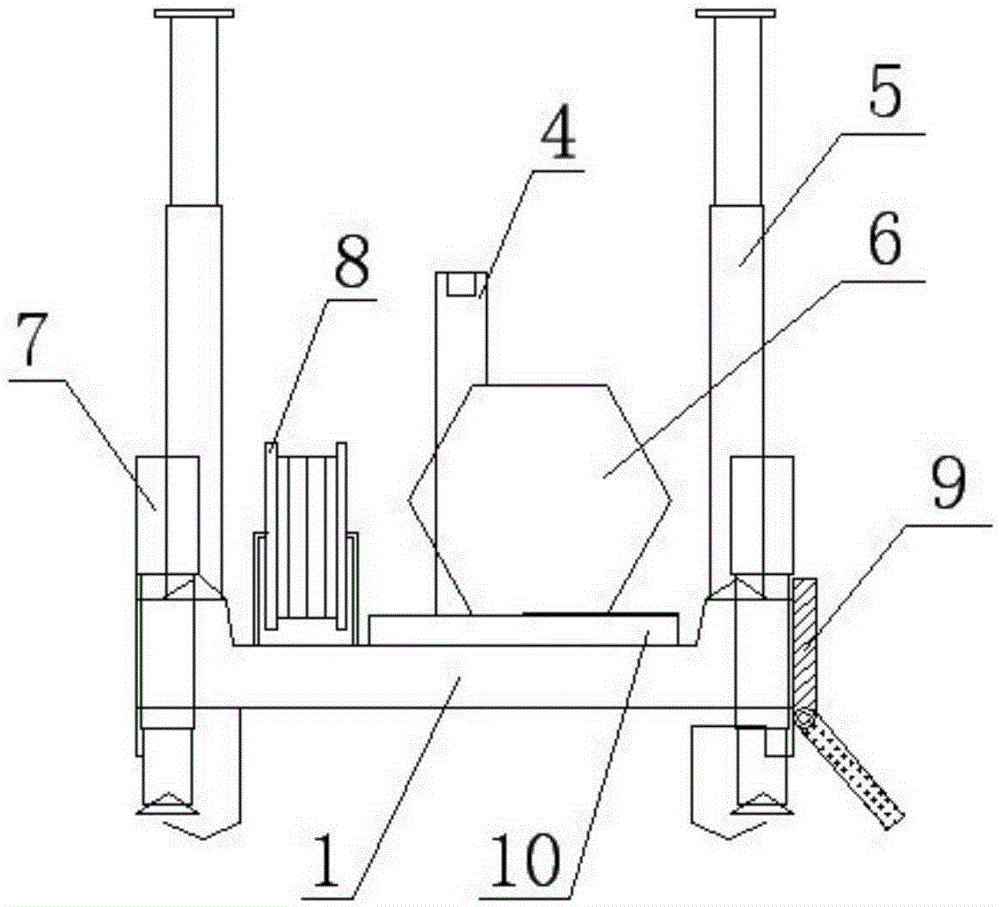

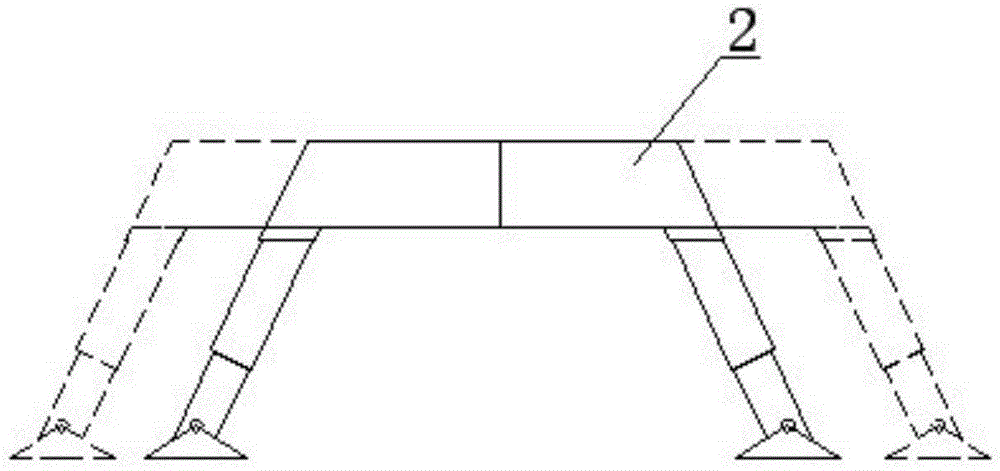

[0031] Such as Figure 1 to Figure 5 Said, the long-distance armless rake mining trolley of the present invention is mainly composed of a traveling mechanism 1, a power and operating system 3, an electric rake winch 6, a vehicle crane 4, a frog hydraulic outrigger, The vehicle body fixed oil cylinder 5, the folding baffle 9 and the rake bucket and the ejection gun components; the electric rake winch 6 is connected to the body chassis through the rotating shaft disk 10, and is placed in the stope or roadway, which can realize the three sides and the tail. Xiang rake mine; the frog-type hydraulic legs include a total of two pairs of front and rear frog-type hydraulic legs, one of which is the middle frog-type hydraulic leg 2 placed in the front of the body chassis, and one pair is the rear frog-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com