An absorption heat pump with a steam nozzle

An absorption heat pump and steam technology, applied in the direction of adsorption machines, machine operation, energy-saving heating/cooling, etc., can solve problems such as low efficiency, difficult output temperature of absorption heat pumps, low evaporation temperature and pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

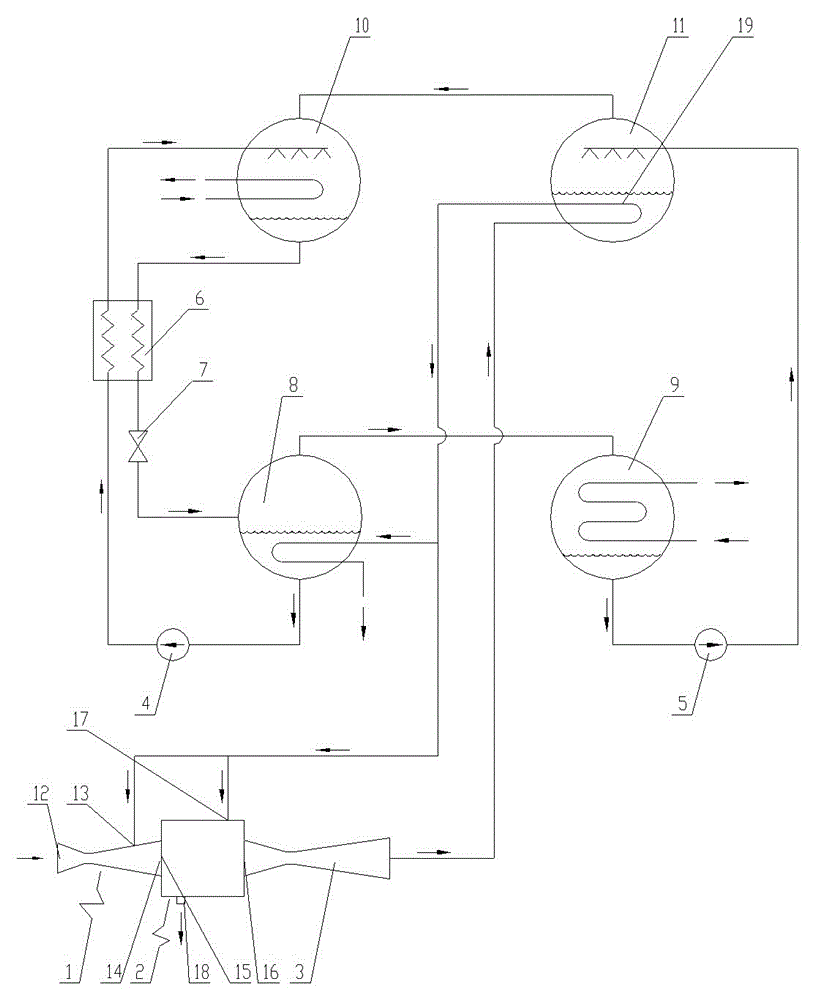

[0010] See figure 1 , which includes a solution pump 4, a refrigerant pump 5, a solution heat exchanger 6, a throttle valve 7, a generator 8, a condenser 9, an absorber 10, and an evaporator 11. The evaporator 11 is equipped with a refrigerant liquid, and the refrigerant liquid is formed A heating steam pipe is arranged in the cavity of the chamber, and the absorber 10 and the generator 8 are equipped with an absorption solution, which also includes an expansion tube 1, a vapor-liquid heat exchanger 2, and a diffuser tube 3, and the expansion tube 1 has an expansion tube inlet 12. Circulation inlet 13, expansion tube outlet 14, heat exchange tubes are arranged in the vapor-liquid heat exchanger 2 (not shown in the figure, which belongs to the existing mature structure), and the vapor-liquid heat exchanger 2 has an expansion steam inlet 15, Expansion steam outlet 16, heating steam inlet 17, condensed water outlet 18, expansion steam inlet 15, and expansion steam outlet 16 are r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap