Glass layer frame and manufacturing method thereof

A glass shelf and glass substrate technology, which is used in household refrigeration devices, decorative arts, lighting and heating equipment, etc., can solve the problem of no lighting function, and achieve the effect of adjustable brightness, long life, and increased brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with accompanying drawings and examples of implementation.

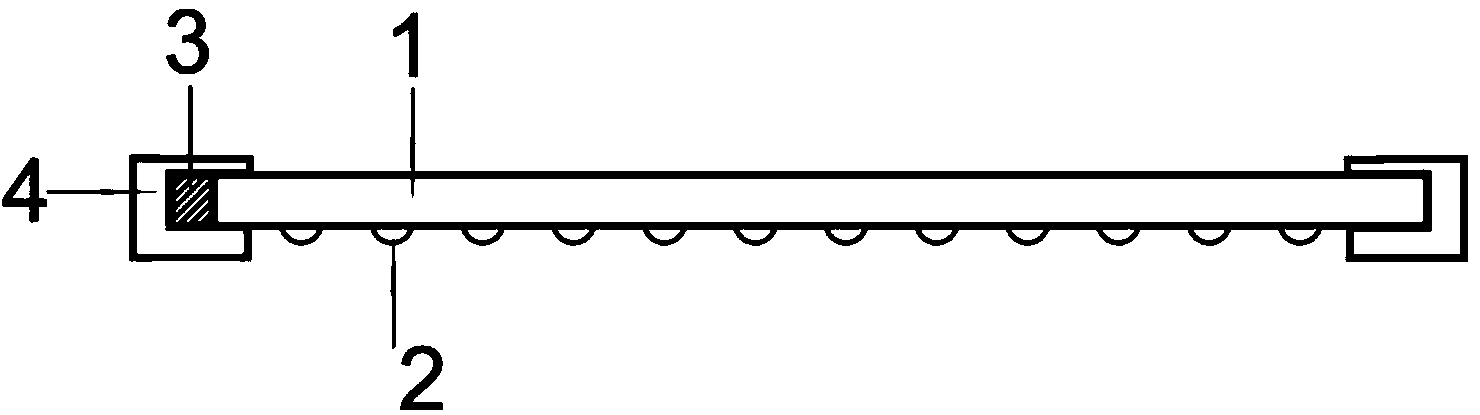

[0021] as attached figure 1 As shown, the glass substrate 1 is flat ordinary or ultra-clear float glass or embossed transparent glass with a thickness of 3-6mm; The concave-convex refraction pattern layer that is tempered after hot-melt embossing and other processes; the linear cold light source 3 for lighting and sterilization is the light source for refrigerator lighting and sterilization, and is arranged on the inner or outer side of the tempered glass plate; the injection molding frame support frame 4 is It is completed by injection molding around the entire periphery of the mold.

[0022] The light-guiding concave-convex layer 2 can also produce various patterns and light and shadow effects required by screen embossing, acid etching engraving, laser engraving, sandblasting engraving, hot-melt embossing, etc. according to the needs of custome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com