Transmission locking mechanism of automatic target

A transmission lock and motor technology, which is applied in the field of shooting training equipment, can solve problems such as power supply difficulties, target stuck, bulky, etc., and achieve the effects of clear transmission mechanism, reduction of cumulative transmission error, and uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

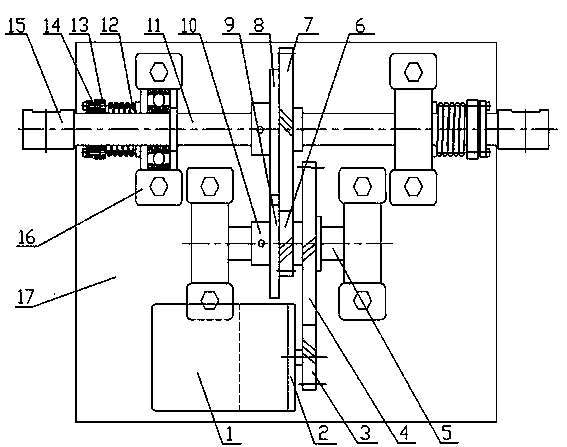

[0018] The structure of the transmission locking mechanism of the falling target involved in this embodiment is as follows: figure 1 As shown, the transmission locking mechanism for lifting and falling targets consists of motor 1, motor frame 2, gear I3, gear II4, intermediate shaft 5, incomplete gear III6, gear IV7, sheave I8, sheave II9, bushing 10, Main shaft 11, torsion spring 12, spring collar 13, expansion sleeve 14, target pole sleeve 15, bearing unit 16 and base 17 are formed.

[0019] The motor 1 is a DC brushless permanent magnet low-speed synchronous motor, which is small in size and high in torque, can be rotated frequently, has high motor efficiency, and has obvious power-saving effects.

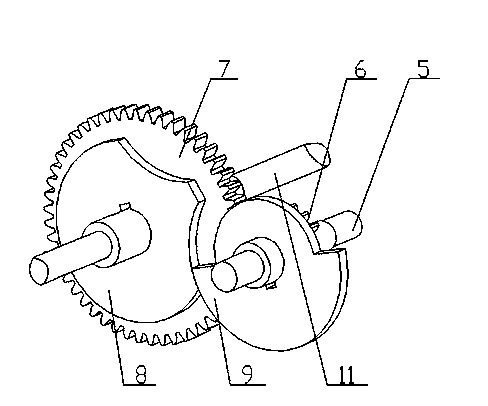

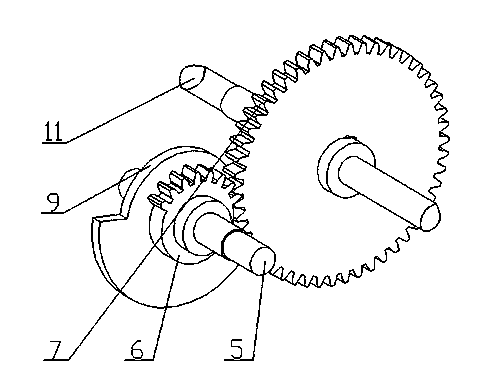

[0020] The incomplete gear III6, gear IV7, sheave I8 and sheave II9 form an incomplete gear-sheave combined mechanism, and its installation position is as follows: figure 2 with image 3 shown.

[0021] When designing the incomplete gear-groove combined mechanism, it needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com