Simulation load balancing method and device for aircraft engine crankcase strength tests

A technology for aircraft engine and strength test, applied in the field of aircraft engine, can solve the problems of small load range, difficult to meet high-strength test, etc., and achieve the effect of large load range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to the drawings and embodiments.

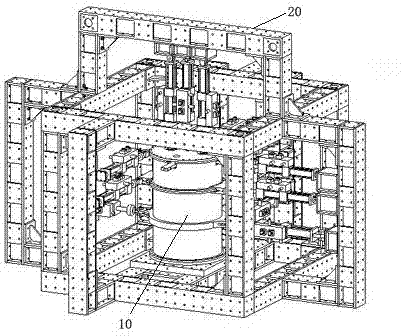

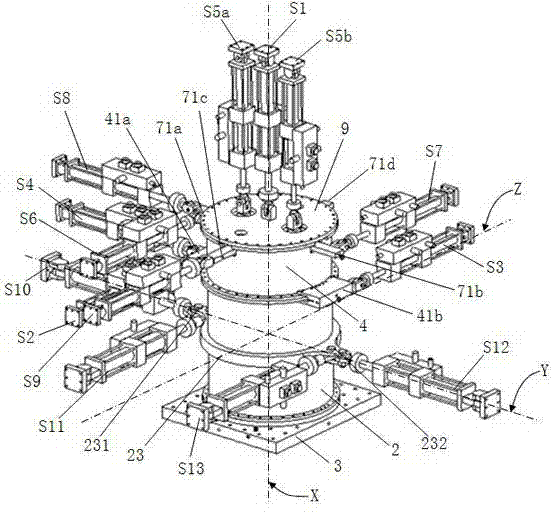

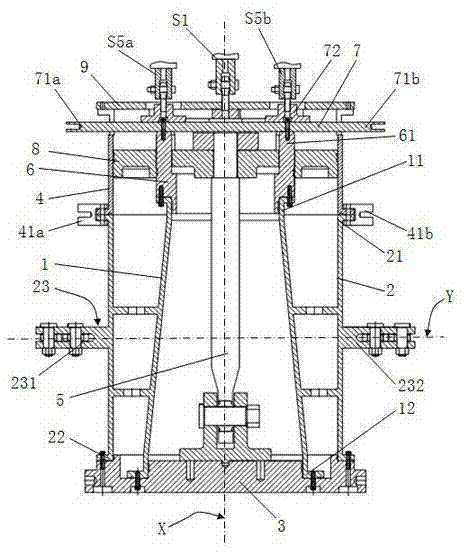

[0016] Such as Figure 1 to Figure 3 As shown, the simulated load balance method of the aircraft engine casing strength test described in the embodiment of the present invention, the casing 10 has an inner cavity body 1 and an outer cavity body 2, and the outer cavity body 2 has an outer cavity upper flange 21, an outer cavity body 2, and an outer cavity body 2. The cavity lower flange 22 and the middle flange 23, the inner cavity body 1 has the inner cavity upper flange 11 protruding from the outer cavity body 2 and the inner cavity lower flange 12, and the middle flange 23 has a symmetrical first loading boss 231 And the second loading boss 232, take the central axis of the casing as the X axis, the connecting line direction of the first loading boss and the second loading boss as the Y axis, and take the horizontal vertical line on the same horizontal plane as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com