Elastic wave foil type cylindrical surface air film flexible supporting structure

A flexible support and corrugated foil technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of wear of the rotor of the moving ring and the static ring, deformation of the sealing gas film, instability of the gas film, etc., to improve the support performance , Uniform structural stiffness, improve the effect of flexible support buffering and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

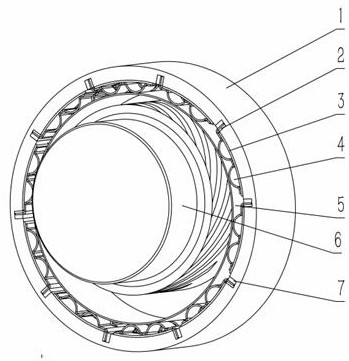

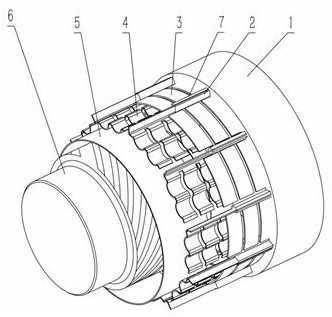

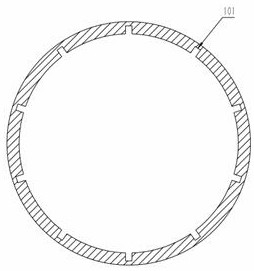

[0023] Embodiment 1: as Figure 1-8 As shown, an elastic wave foil type cylindrical air film flexible support structure includes an outer support sleeve 1, a flat plate 2, a corrugated foil 4, a static ring 5, a moving ring rotor 6, and a pressure block 7; There is a slot 601, the static ring 5 is eccentrically installed on the moving ring rotor 6, the outer support sleeve 1 and the static ring 5 are coaxially installed on the external structure, and the inner wall of the outer support sleeve 1 is provided with 8 card slots 101 , the corrugated foil 4 is provided with an arc plate 3, the arc plate 3 is located on the inner peripheral wall of the outer support sleeve 1, the flat plate 2 is installed on the inner side of the card slot 101, and the corrugated foil 4 is installed close to the flat plate 2 In the card slot 101, the pressing block 7 is pressed into the other side of the card slot 101, the corrugated foil 4 is in linear contact with the outer wall of the static ring ...

Embodiment 2

[0026] Embodiment 2: as Figure 1-8 As shown, an elastic wave foil type cylindrical air film flexible support structure includes an outer support sleeve 1, a flat plate 2, a corrugated foil 4, a static ring 5, a moving ring rotor 6, and a pressure block 7; There is a slot 601, the static ring 5 is eccentrically installed on the moving ring rotor 6, the outer support sleeve 1 and the static ring 5 are coaxially installed on the external structure, and the inner wall of the outer support sleeve 1 is provided with 12 card slots 101 , the corrugated foil 4 is provided with an arc plate 3, the arc plate 3 is located on the inner peripheral wall of the outer support sleeve 1, the flat plate 2 is installed on the inner side of the card slot 101, and the corrugated foil 4 is installed close to the flat plate 2 In the card slot 101, the pressing block 7 is pressed into the other side of the card slot 101, the corrugated foil 4 is in linear contact with the outer wall of the static ring...

Embodiment 3

[0029] Embodiment 3: as Figure 1-8 As shown, an elastic wave foil type cylindrical air film flexible support structure includes an outer support sleeve 1, a flat plate 2, a corrugated foil 4, a static ring 5, a moving ring rotor 6, and a pressure block 7; There are slots 601, the static ring 5 is eccentrically installed on the moving ring rotor 6, the outer support sleeve 1 and the static ring 5 are coaxially installed on the external structure, and the inner wall of the outer support sleeve 1 is provided with 16 card slots 101 , the corrugated foil 4 is provided with an arc plate 3, the arc plate 3 is located on the inner peripheral wall of the outer support sleeve 1, the flat plate 2 is installed on the inner side of the card slot 101, and the corrugated foil 4 is installed close to the flat plate 2 In the card slot 101, the pressing block 7 is pressed into the other side of the card slot 101, the corrugated foil 4 is in linear contact with the outer wall of the static ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com