Control rod guide tube and fuel assembly

A technology for controlling rod guide tubes and fuel rods, which is applied in the field of reactor components, can solve problems such as limiting the CHF performance of fuel assemblies, and achieve the effects of improving rod dropping performance, shortening rod dropping time, and optimizing CHF performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

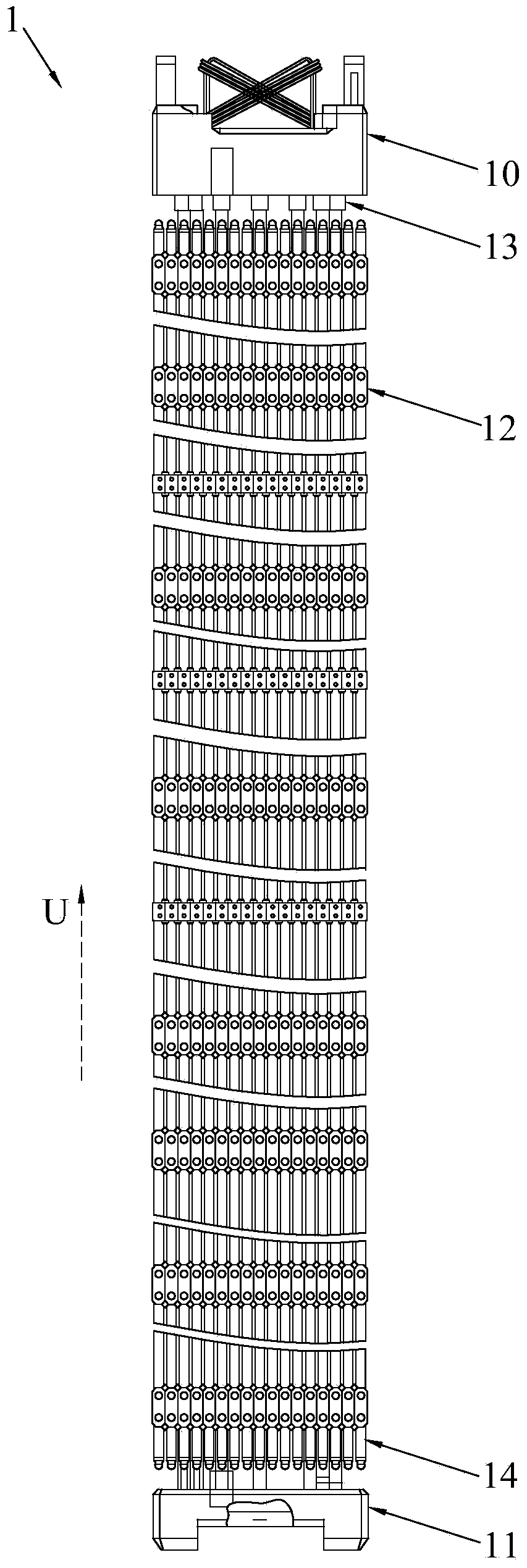

[0029] As shown in Figure 1, the fuel assembly 1 of the present invention includes an upper tube base 10, a lower tube base 11, a plurality of positioning grids 12, a control rod guide tube 13 and a fuel rod 14, and the control rod guide tube 13 and the fuel rod 14 Respectively inserted in a plurality of said positioning grids 12 parallel to each other, the uppermost said positioning grids 12 are matched and connected with said upper tube base 10, and the lowermost said positioning grids 12 are connected with said lower tube bases 11 matching connections. In practical applications, the plurality of spacer grids 12 may be an integrated structure. U in FIG. 1 is the flow direction of the coolant fluid in the fuel assembly 1 , that is, it flows from bottom to top.

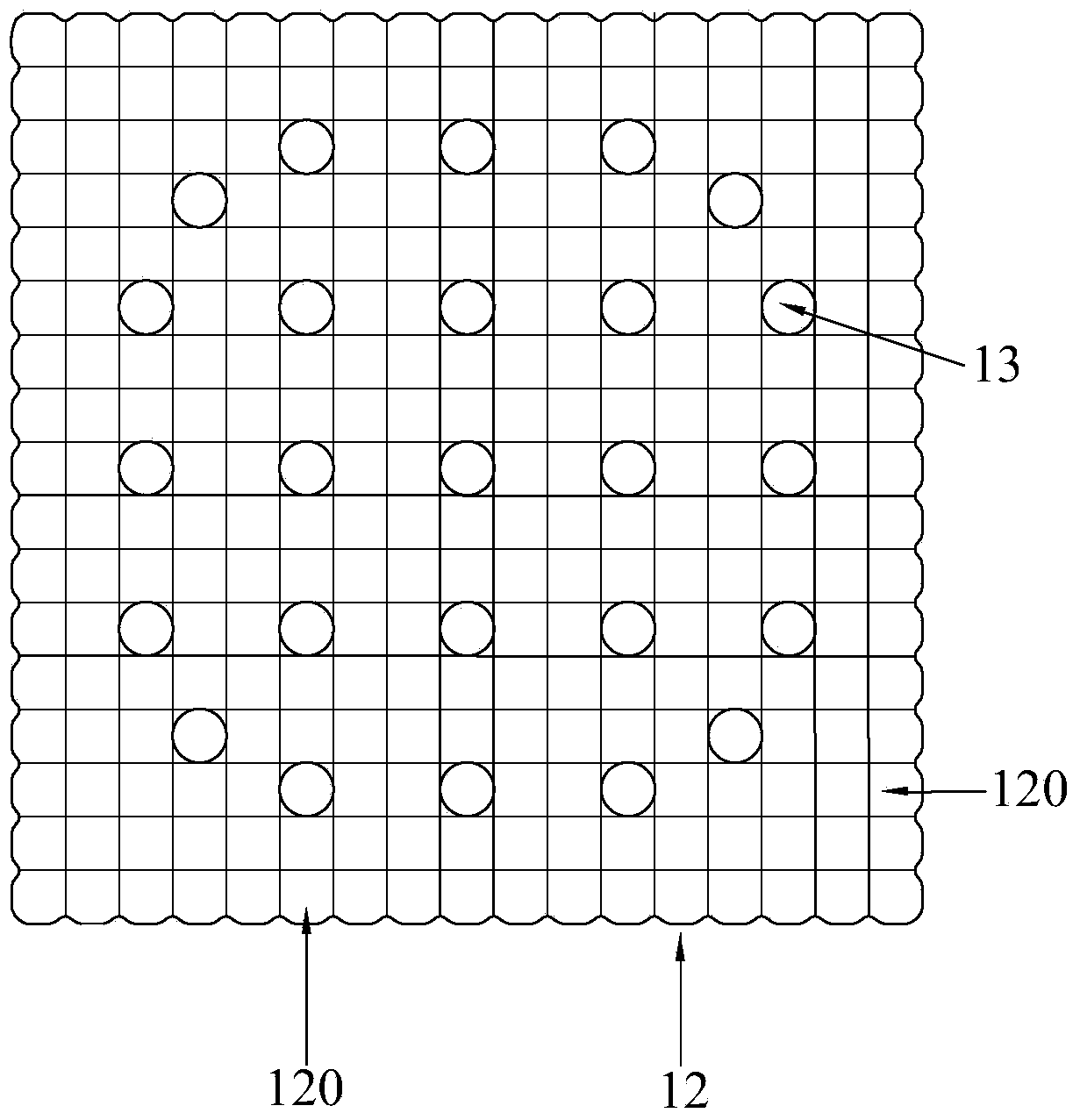

[0030] refer to figure 2 As shown, the middle of the positioning grid 12 forms a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com