A grounding system for high-voltage switchgear and its processing method

A technology of high-voltage switchgear and grounding system, which is applied in the direction of grounding device, switchgear, electrical components, etc. Grade and quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

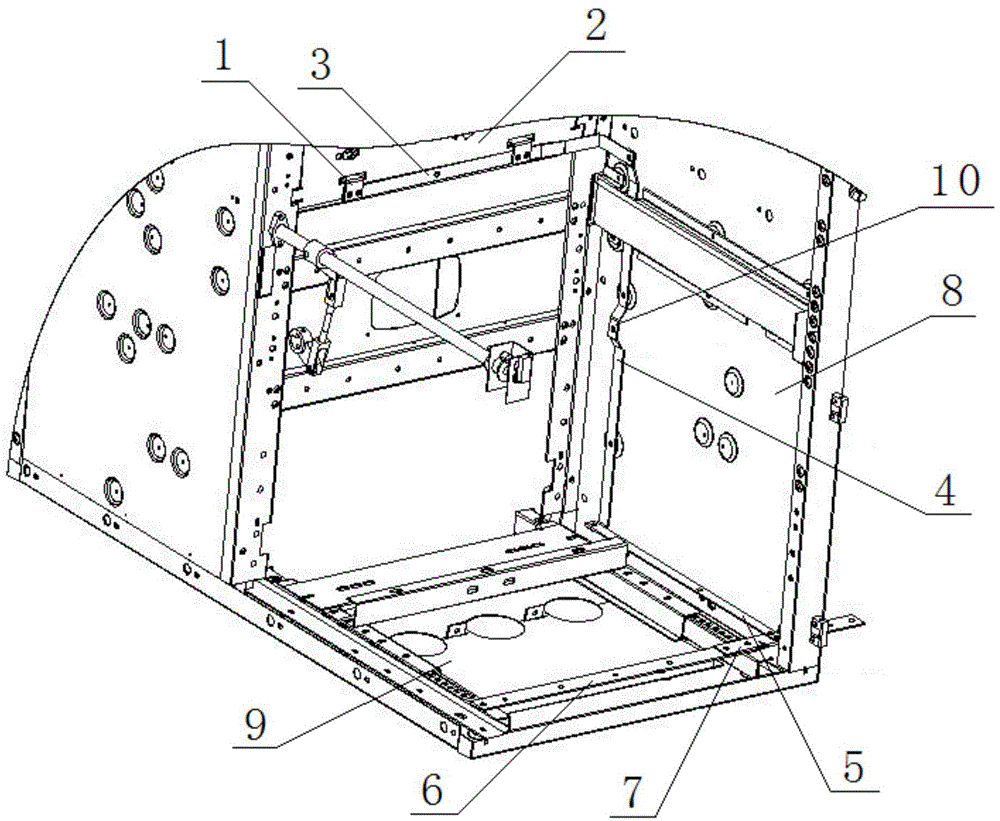

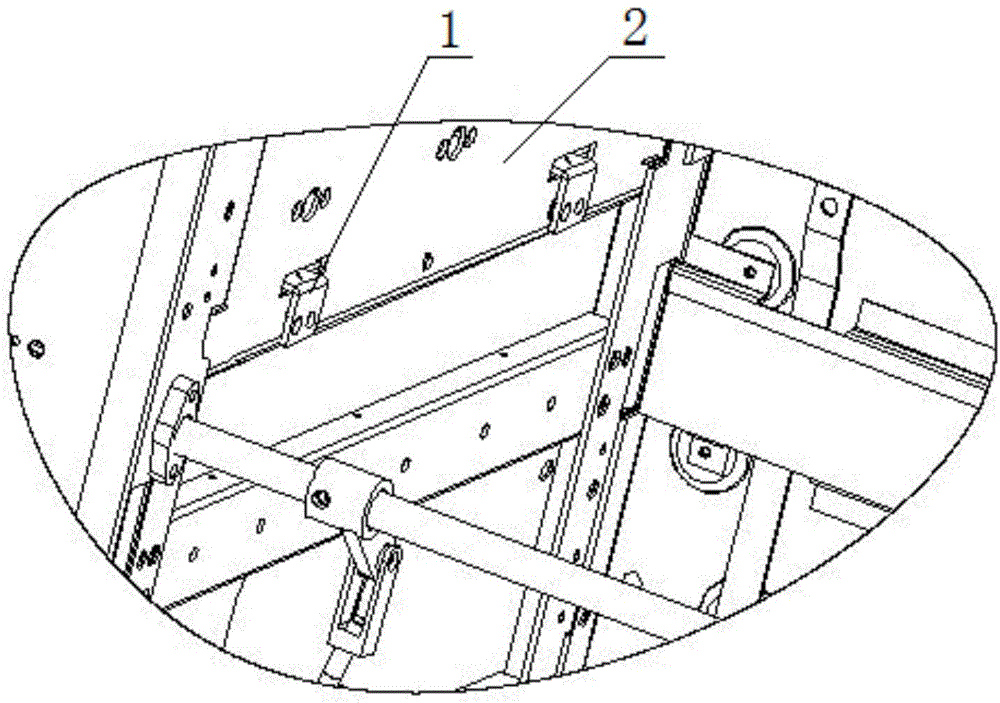

[0019] figure 1 It is a structural schematic diagram of the grounding system used in the high-voltage switchgear of the present invention, figure 2 Schematic diagram of a partially enlarged structure. Depend on Figure 1-Figure 2 Combining the structures shown, it can be seen that this grounding system for high-voltage switchgear includes handcart grounding bar 1, contact box mounting plate 2, left rear side plate 8 and bottom plate 9, contact box mounting plate 2 and left rear side plate 8 are adjacently arranged and vertically installed together, and the contact box mounting plate 2, the left rear side plate 8 and the bottom plate 9 are vertically installed in pairs; the relative positions of the handcart ground bar 1 and the contact box mounting plate 2 are set There are regular hexagonal holes for fixedly installing the first grounding bar 3, and the left rear side plate 8 is provided with two bosses for the fixed installation of the second grounding bar 4, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com