Auxiliary valve controlled self-cleaning main valve

An auxiliary valve, self-cleaning technology, applied in the direction of valve operation/release device, valve detail, valve device, etc., can solve problems such as adding operation control piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

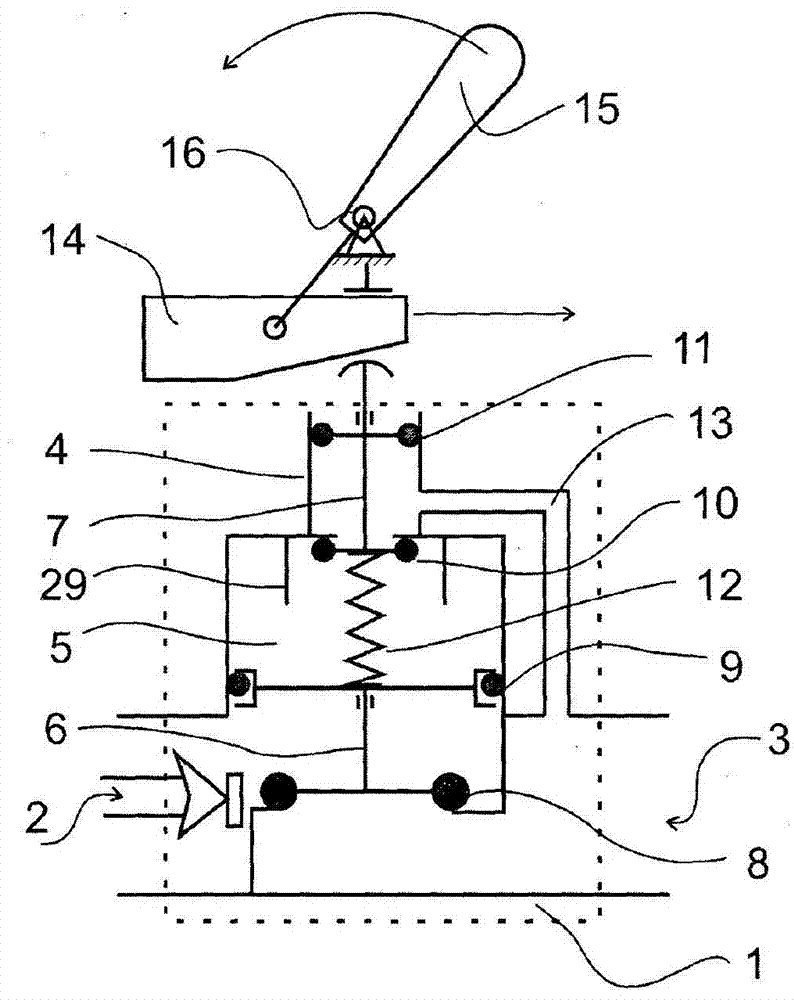

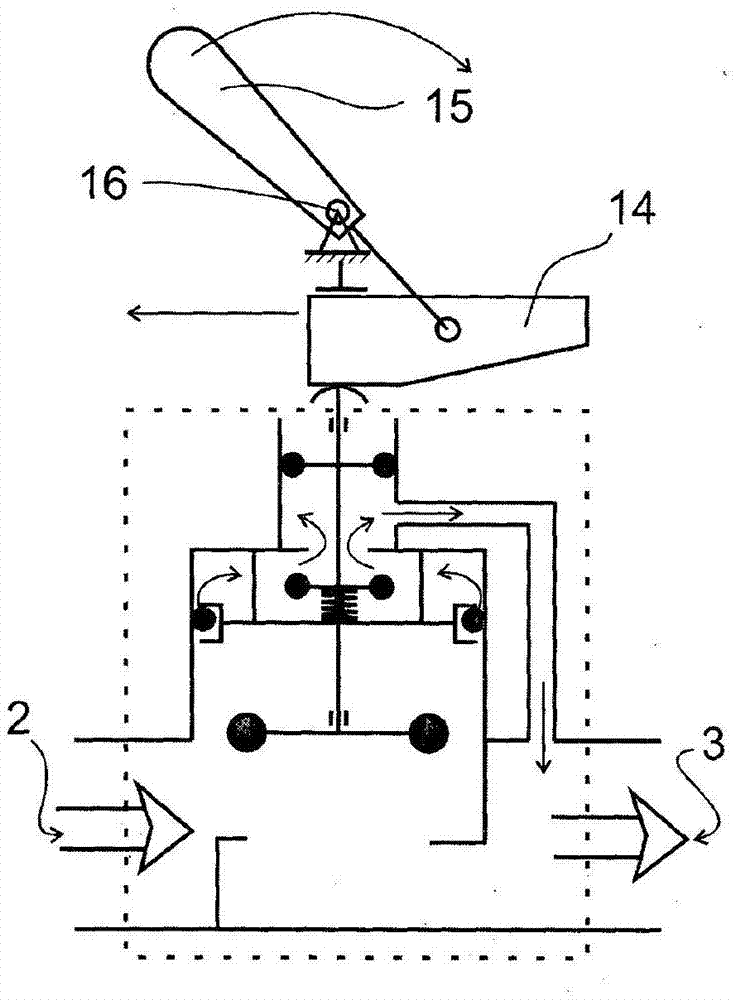

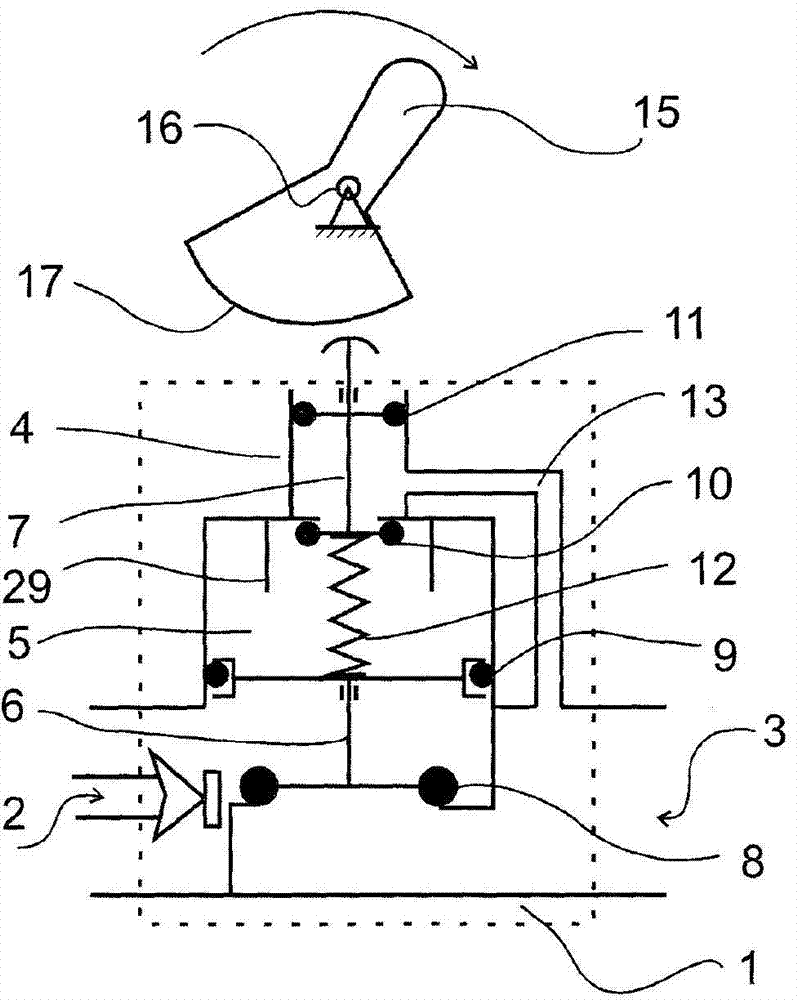

[0024] according to Figure 1a and Figure 1b In the first embodiment of the invention shown, the valve body 1 includes an inlet hole 2 and an outlet hole 3 interconnected with the flow-through holes. The portion enclosed by the dashed box illustrates the inventor's earlier patent, which is adapted for use with the present invention, as will be set forth in the following description.

[0025] The main flow passage of the valve body 1 can be closed or opened by the main closing element 8 depending on the position of the piston 6 . The main closing element is located on one (bottom) side of the piston 6 , while on its other (upper) side there is a brake O-ring 9 adjoining the control chamber 5 . As shown, the bumper 29 limits the upward movement of the piston 6 . These buffers can be separate elements or a single tube with a suitably sized orifice.

[0026] On one side of the control chamber 5 is provided an auxiliary valve 4 , which flows through holes so that the liquid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com