A collecting device for a sugarcane harvester

A technology of aggregating device and combine harvester, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increasing labor intensity, reducing work efficiency, reducing output, etc., and achieves improved production efficiency and compact structure. , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

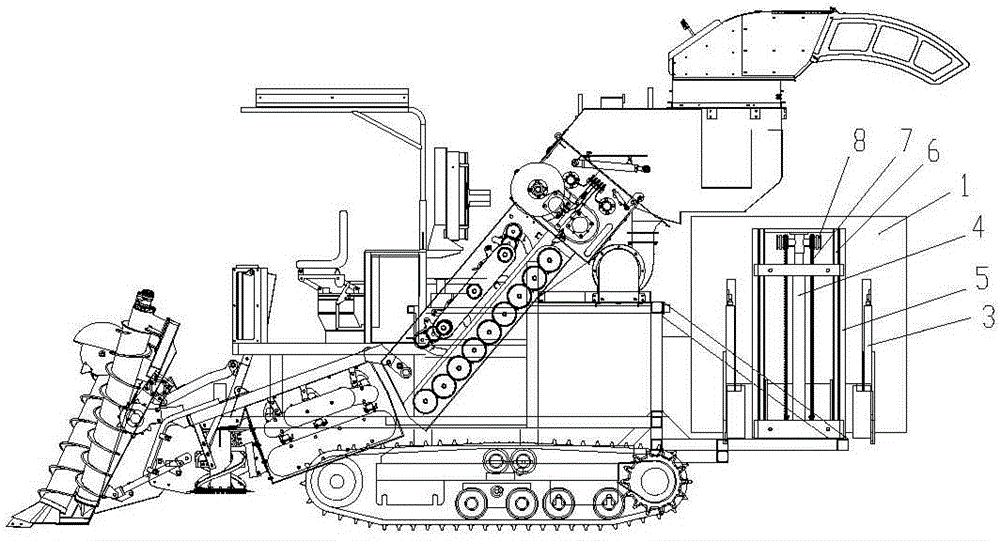

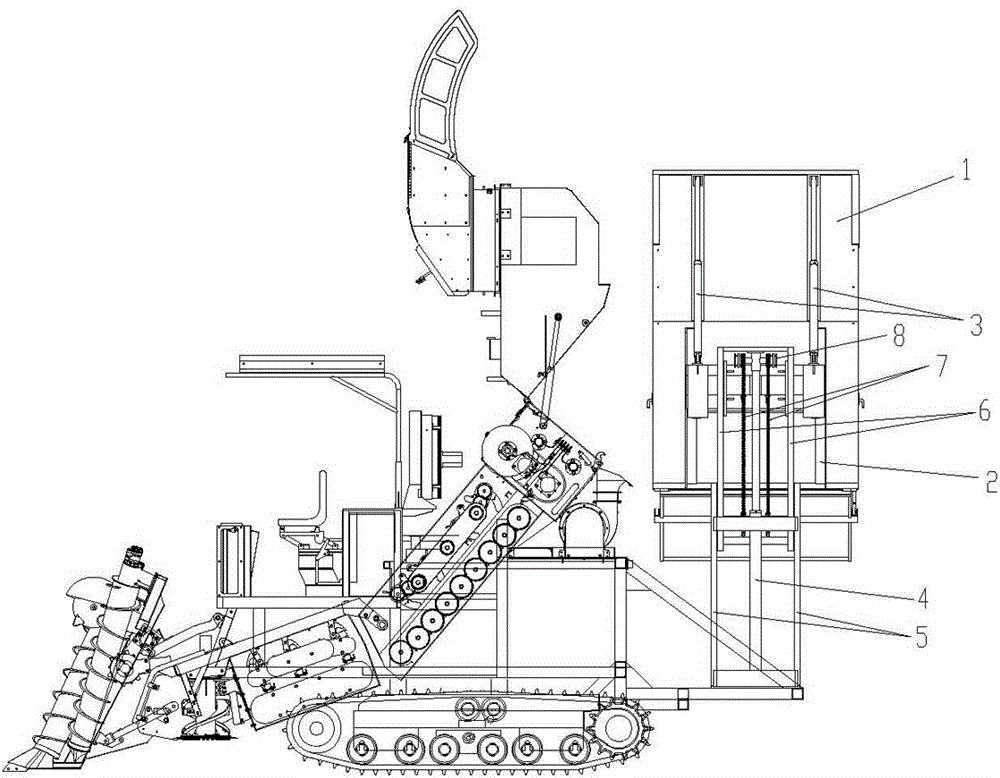

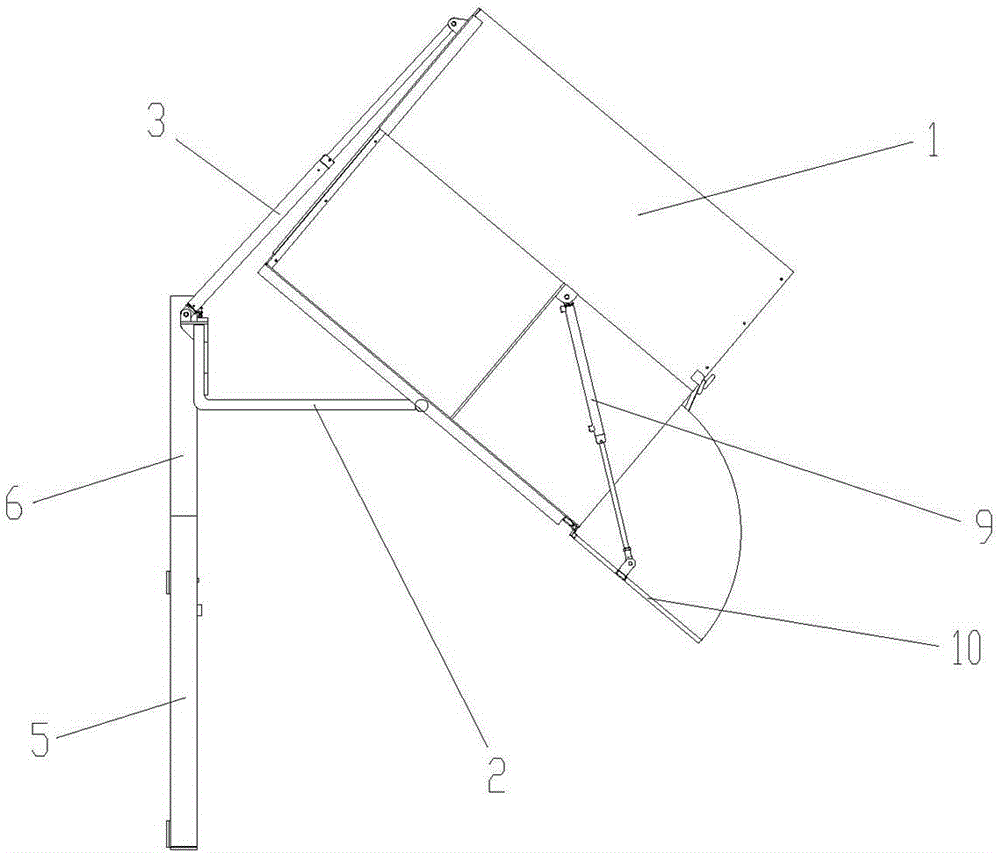

[0017] Such as figure 1 As shown in -4, a collection device of a sugarcane combine harvester includes a collection box 1, a collection box carrier frame 2, two collection box dumping cylinders 3, a lifting cylinder 4 and a portal frame. The portal frame includes Two slide rails 5, two slide bars 6 and two lifting chains 7, the portal frame is vertically installed on one side of the rack tail, and the two slide bars 6 are embedded slidingly connected in the two slide rails 5, The upper end connecting rods of the two slide bars 6 are provided with a sprocket frame 8, and one end of the hoisting chain 7 is connected with the collection box carrier frame 2, and the other end of the lifting chain 7 is connected with the upper ends of the two slide bars 6 through the sprocket frame 8. The rods are fixedly connected, the lower end of the lifting cylinder 4 is connected to the tail frame, the upper end of the lifting cylinder 4 is connected with the upper connecting rods of the two sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com