Ore dressing stirring tank

A stirring tank and stirring shaft technology, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, dissolution, etc., can solve the problems of high density of ore pulp, affecting the full mixing reaction of ore pulp and beneficiation drugs, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

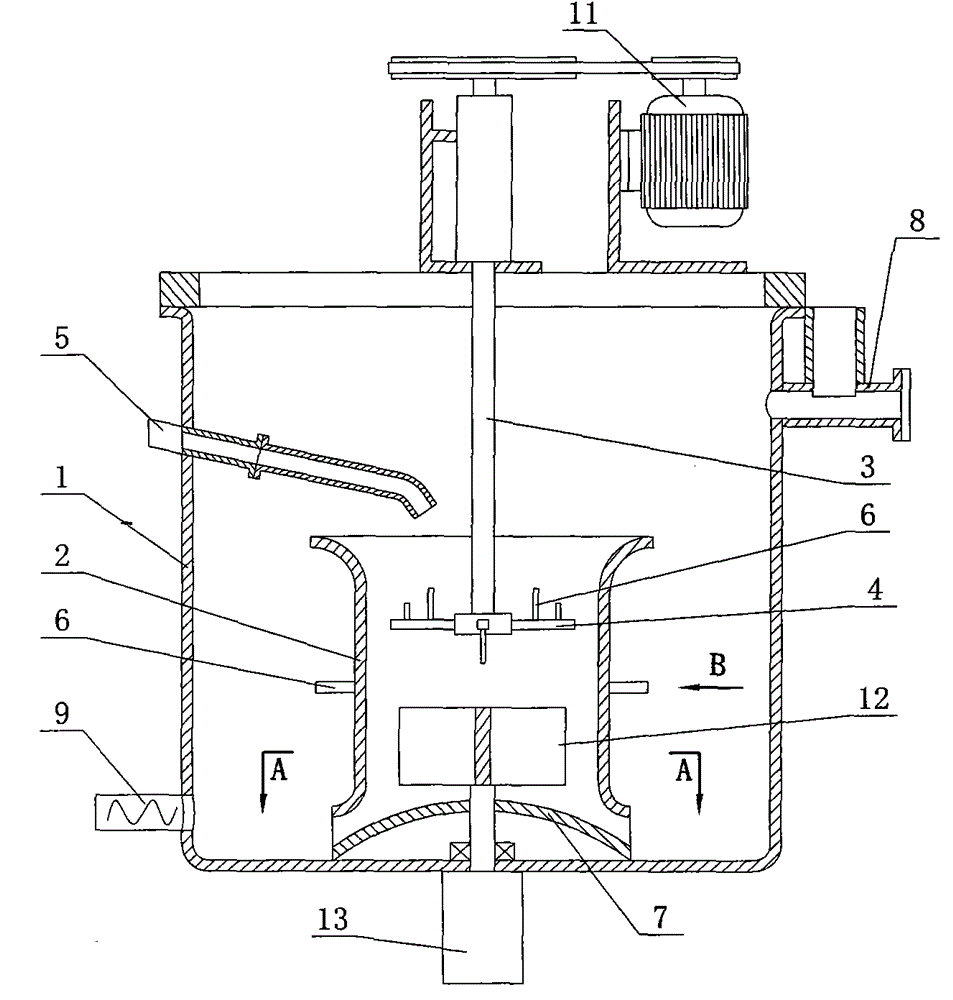

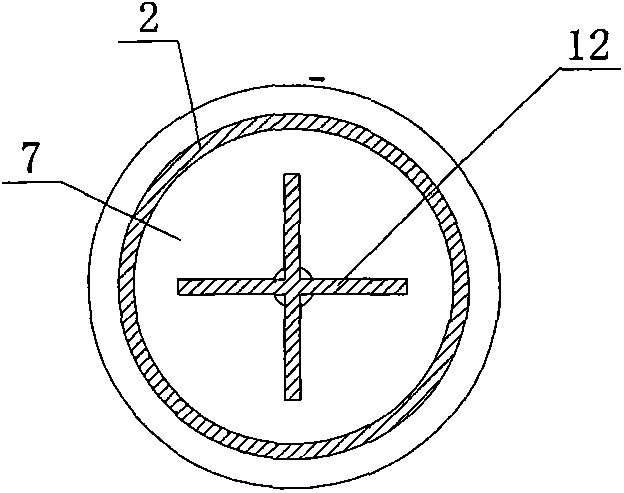

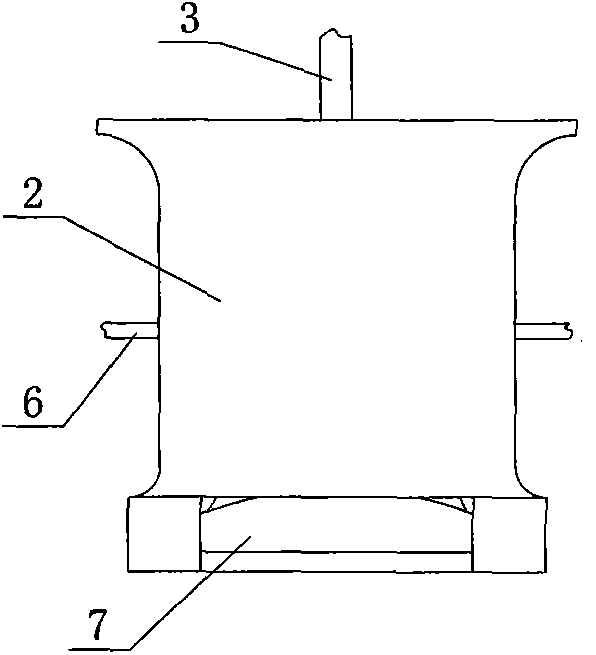

[0013] like figure 1 The mineral dressing stirring tank shown comprises a stirring tank body 1 with a bottom seal and an open top, and a dispersion cylinder 2 is connected in the stirring tank body 1, and the top opening of the dispersion cylinder 2 is provided with a discharge port at the bottom. The tank body 1 is rotatably connected with a stirring shaft 3 driven by a power unit and extending into the dispersion cylinder 2 at the bottom. The top of the shaft is rotatably connected to the support frame and connected to the power output shaft of the motor 11. The stirring shaft 3 is connected with a plurality of stirring columns 4 with a ring cloth and stretched out. Each stirring column 4 is equipped with a plurality of different lengths And vertically arranged sub-stirrer rods 6, a plurality of sub-stirrer rods 6 gradually become shorter from the inner side of the agitation column 4 to enhance the agitation effect. , the discharge port of the ore feeding pipe 5 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com