Full-automatic grinding machine and grinding method thereof

A fully automatic grinding machine, technology to be ground, applied in the direction of grinding machine tool parts, grinding feed movement, grinding/polishing equipment, etc., can solve the problems of low efficiency, accuracy and detection stability, and achieve automation The effect of high degree, high efficiency and fast grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

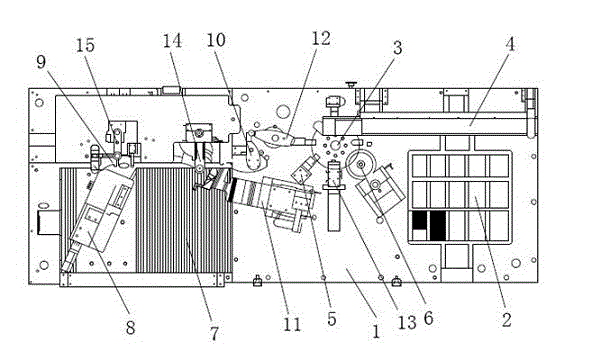

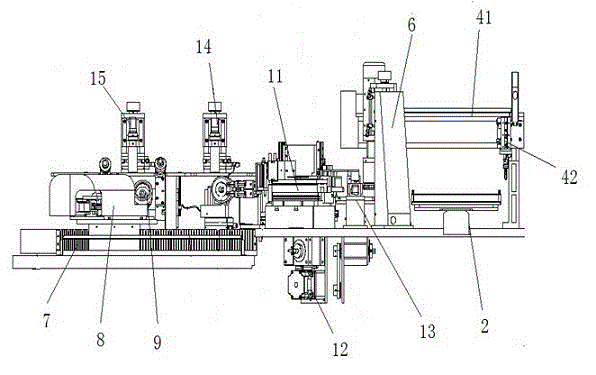

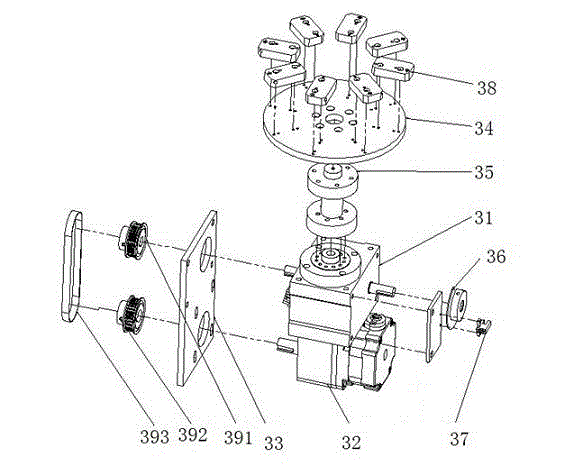

[0031] Please refer to figure 1 , the figure shows a fully automatic grinding machine, including a machine platform 1, and also includes a drill disc 2 installed on one side of the machine platform 1, which operates in two-way transportation and intermittently rotates in the circumferential direction The rotary table device 3, the drill pin grabbing device 4 for clamping drill pins back and forth between the drill pin disc 2 and the rotary table device 3, the drill pin cleaning device 5 for cleaning the drill pins transported to the rotary table device 3, with The drill bit appearance inspection device 6 for detecting the drill pins delivered to the turntable device 3, the mobile table 7 installed on the other side of the machine table 1, the mobile grinding and clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com