Driving device of rope sawing machine

A driving device, wire saw machine technology, applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problem that the tensioning device is not suitable for application, and achieve the effect of light weight, easy realization, and high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

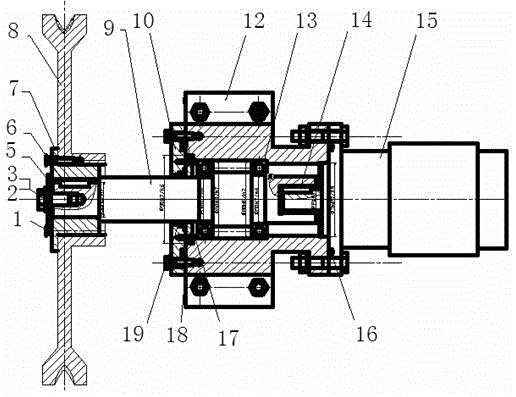

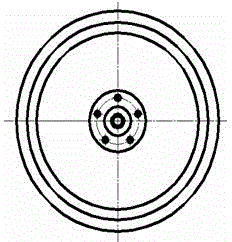

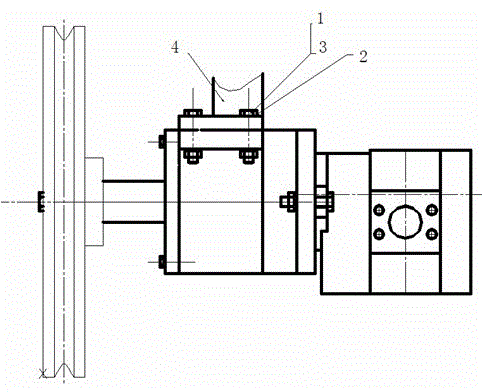

[0021] A driving device for a wire saw machine, such as Figure 1 to Figure 3 As shown, the device includes: a bearing seat 12 installed on the channel steel 20 of the fixed frame, a gear motor 15, a driving wheel 8 and a driving wheel shaft 9, and a bearing 13 is arranged in the bearing seat; Head nut 3, washer 2 are fixed on the channel steel 4. One end of the drive wheel shaft is installed with the bearing, and the other end is fixedly connected with the drive wheel through the drive wheel hole sleeve and the sleeve baffle plate; it is locked by the hexagon head bolt 1 and the washer 2, and the movement and torque are transmitted through the drive wheel flat key 6 . The gear motor is a hydraulic motor, and the driving wheel is driven by hydraulic pressure. Hydraulic motors are more suitable for underwater operations. It is not only light in weight and small in size, but also easy to realize underwater sealing and stepless speed regulation. The hydraulic motor performs st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com