A tooth row device and its working method

A technology of tooth row and tooth sheet, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of inability to process operations and unusable paper, and achieve small number, strong applicability, and reduce paper waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

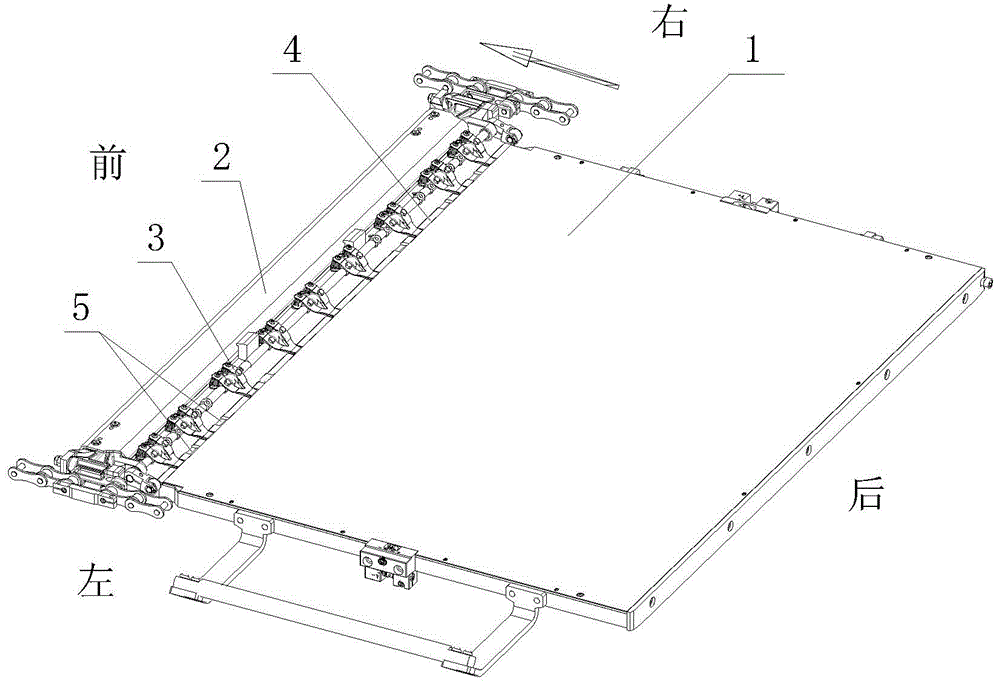

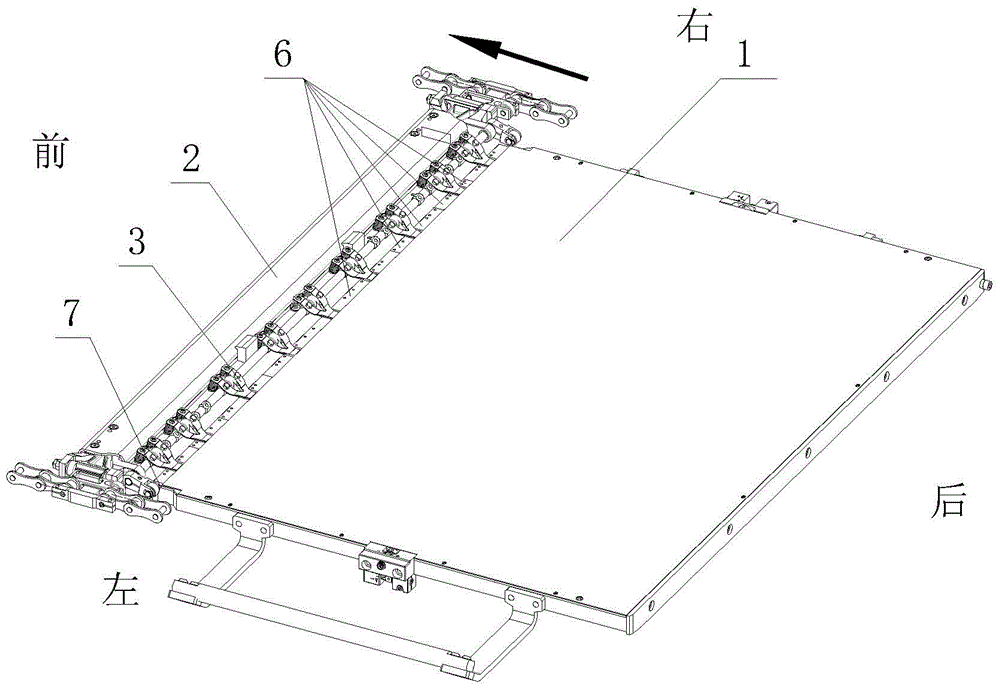

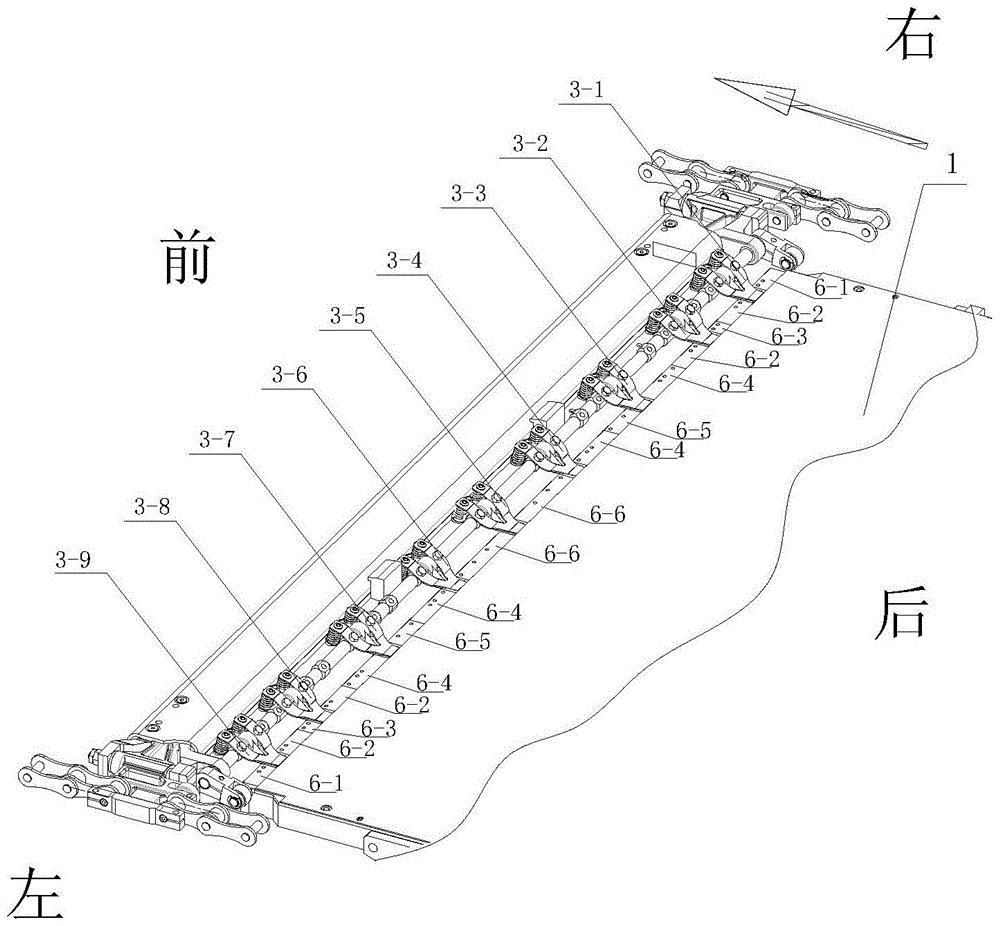

[0032] Embodiment: a kind of pad tooth row device (see figure 2 ), including the row of teeth 2 and the paper docking station 1, characterized in that a pad assembly 6 that fills the gap between the teeth of the row of teeth 2 is installed at the paper output end of the paper docking station 1.

[0033] The paper outlet side of the paper receiving table 1 is fixedly connected to the installation bar 7 ; the spacer assembly 6 is fixedly installed on the installation bar 7 .

[0034] When the tooth row 2 runs to the paper output end of the paper receiving station 1, the tooth pieces of the tooth row 2 are placed on the mounting bar 7, and the paper held by the tooth pieces is horizontally placed on the table of the paper receiving station 1.

[0035] When the tooth piece of the tooth row 2 is placed on the installation bar 7, the upper surface of the lower tooth piece is flush with the upper surface of the paper receiving table 1.

[0036] The upper surface of the spacer assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com