Tension roller adjustment device for traction machine of film stretching production line

A technology of adjusting device and production line, which is used in thin material handling, transportation and packaging, winding strips, etc., can solve the problem that the structure of the tension roller device is not reasonable enough, the tension roller cannot be adjusted to the film tension, and the load cell cannot accurately measure Film tension and other problems, to achieve the effect of accurate and reliable measurement value and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

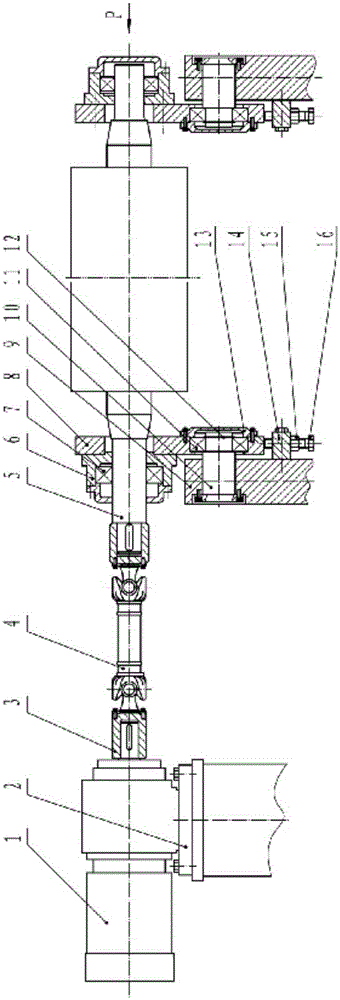

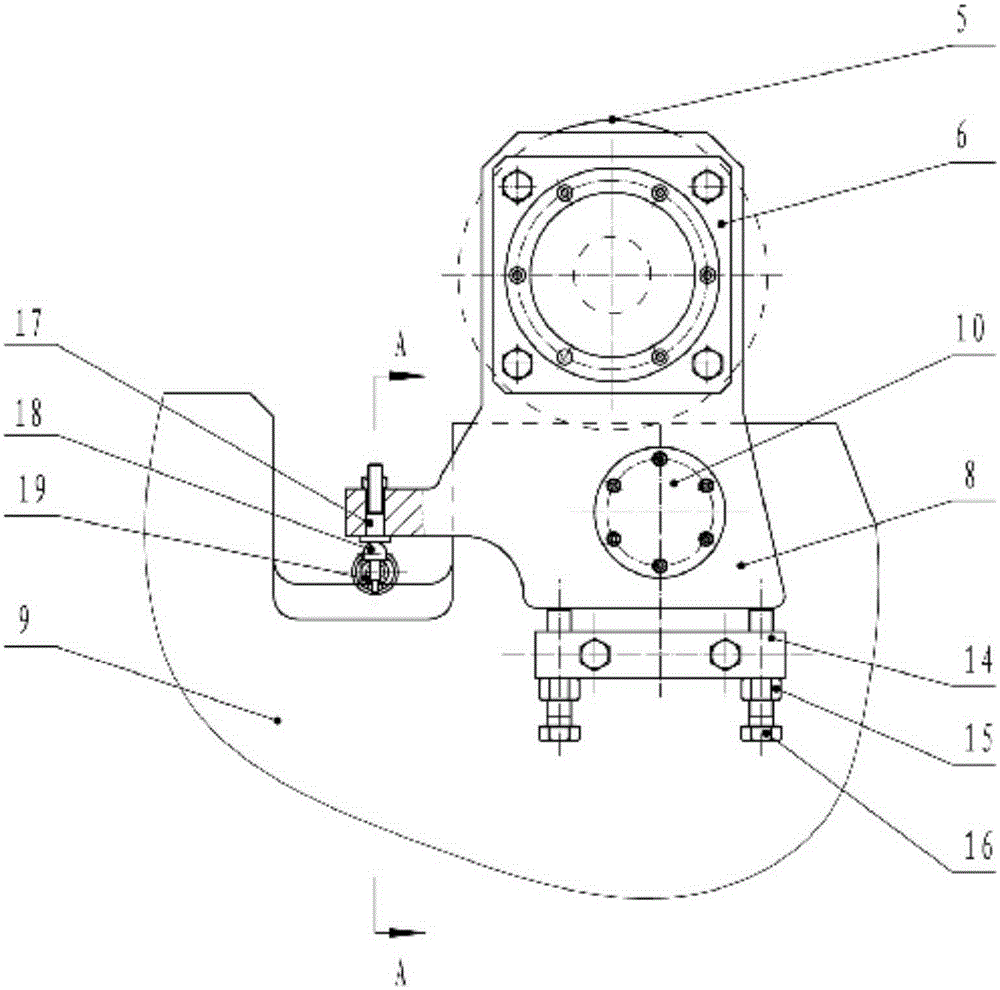

[0017] The overall structure schematic diagram of the embodiment of the tension roller adjustment device of the tractor in the film stretching production line is as follows figure 1 As shown, the motor 1 is fixed on the motor frame 2, and the two ends of the universal joint 4 are respectively connected to the output shaft of the motor 1 and the shaft end of the roller 5 shaft through the shaft sleeve 3 and the key and screw.

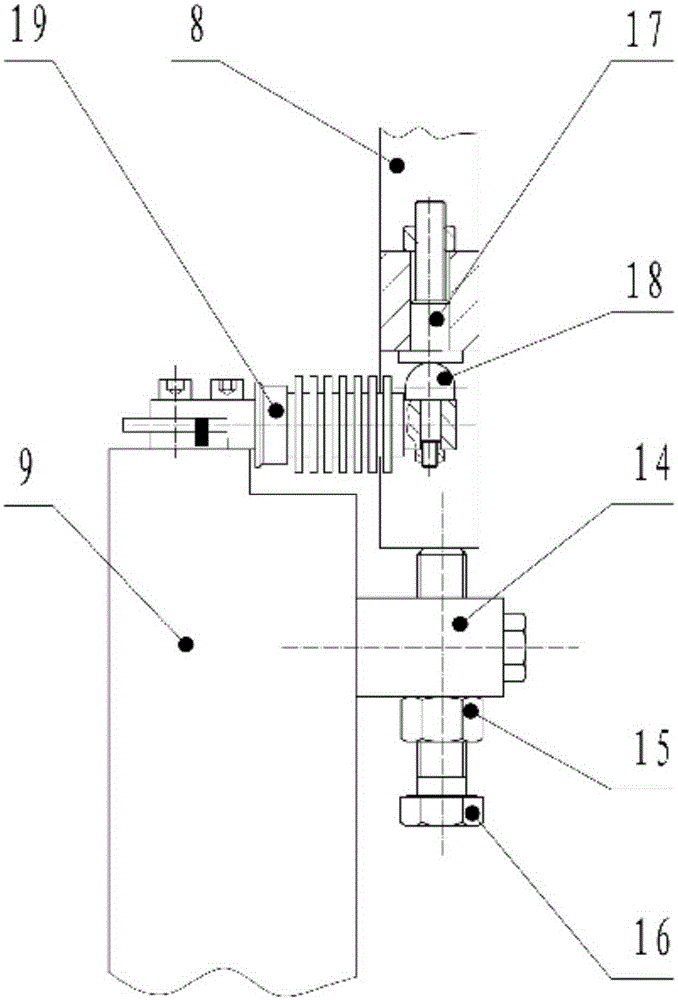

[0018] An identical swing arm 8 is respectively installed at the two ends of the roller 5, and the swing arm 8 has an upper hole and a lower hole. Bearing seat 6 is fixed on the outer side of the upper hole of swing arm 8 by bolt, and the outer ring of roller bearing 7 is fixed in the bearing seat 6, and the roller 5 shaft passes through the upper hole of swing arm 8 and is tightly inserted in the inner ring of roller bearing 7. The outer end of pin shaft 10 is fixedly installed on wallboard 9, and the center line of pin shaft 10 is parallel with roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com