A glass fiber kiln electrode cooling water jacket

A technology for cooling water jackets and water jackets, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor cooling effect and short cooling water residence time, etc., achieve convenient insertion and positioning, good cooling effect, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

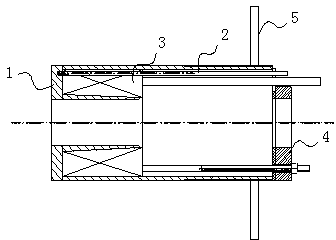

[0022] see figure 1 , the invention discloses a glass fiber kiln electrode cooling water jacket, comprising a water jacket seat 1, a thermocouple insert 2, a cooling water jacket 3, a rear fixing flange 4 and a mounting plate 5; the water jacket seat 1 is installed in the kiln On the furnace body of the furnace, a thermocouple intubation tube 2 and a cooling water jacket 3 are arranged inside, a backing plate and a rear fixing flange 4 are arranged at the end of the water jacket seat 1, and a mounting plate 5 is arranged outside the water jacket seat 1.

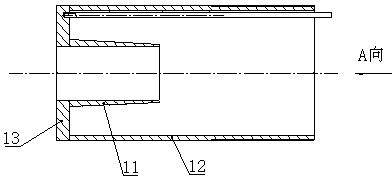

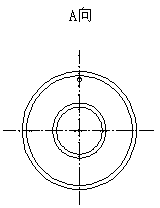

[0023] A water jacket seat 1, such as figure 2 , 3 As shown in , 4, it can be set outside the molybdenum electrode, which includes an inner sleeve 11, an outer sleeve 12 and an annular end plate 13. The outer sleeve 12 is a cylindrical pipe with external threads, and the external thread of the outer sleeve 12 is connected to a kiln. Connected mounting plate 5, the mounting plate 5 is an S-shaped metal plate body, the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com