Dry film hot melt adhesive for pipe joint anticorrosion

A hot-melt adhesive and dry film technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems that cannot meet the needs of dry film construction and anticorrosion, and achieve good bonding performance, Excellent product performance, improved fluidity and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

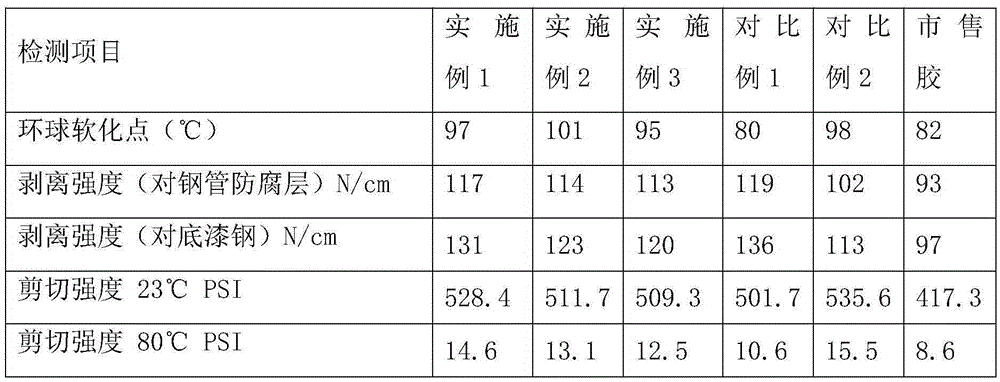

Examples

Embodiment 1

[0022] (1) First dry the raw materials of each component in the formula, and then weigh the mixture of 74% ethylene-acrylate-maleic anhydride terpolymer (EMH) and ethylene-vinyl acetate copolymer (EVA) (EMH and The mass ratio of EVA is 9:1, the VA content of EVA is 30%, the melt index (MI) of EVA is 150g / 10min), weighs 23% rosin resin and C 5 A mixture of petroleum resins is used as a composite tackifying resin (rosin resin and C 5 The mass ratio of petroleum resin is 1:3), 0.8% diphenylmethane diisocyanate, 0.5% antioxidant 1010, 1.3% light calcium carbonate and carbon black;

[0023] (2) Put the raw materials prepared in step (1) into the internal mixer, knead at a temperature of 180-190°C for 2 hours, then stir for 10 minutes and then vacuumize for 30 minutes;

[0024] (3) Apply the mixture prepared in step (2) to a pressure roller to obtain a hot melt adhesive.

Embodiment 2

[0026] (1) First dry the raw materials of each component in the formula, and then weigh the mixture of 70% ethylene-acrylate-maleic anhydride terpolymer (EMH) and ethylene-vinyl acetate copolymer (EVA) (EMH and The mass ratio of EVA is 9:1, the VA content of EVA is 30%, the melt index (MI) of EVA is 150g / 10min), weighs 26% rosin resin and C 5 A mixture of petroleum resins is used as a composite tackifying resin (rosin resin and C 5 The mass ratio of petroleum resin is 1:3), 1% diphenylmethane diisocyanate, 0.8% antioxidant 1010, 2.2% light calcium carbonate and carbon black;

[0027] (2) Put the raw materials prepared in step (1) into the internal mixer, knead at a temperature of 180-190°C for 2 hours, then stir for 10 minutes and then vacuumize for 30 minutes;

[0028] (3) Apply the mixture prepared in step (2) to a pressure roller to obtain a hot melt adhesive.

Embodiment 3

[0030] (1) First dry the raw materials of each component in the formula, and then weigh the mixture of 78% ethylene-acrylate-maleic anhydride terpolymer (EMH) and ethylene-vinyl acetate copolymer (EVA), (EMH The mass ratio with EVA is 9:1, the VA content of EVA is 30%, the melt index (MI) of EVA is 150g / 10min), weigh 18% rosin resin and C 5 A mixture of petroleum resins is used as a composite tackifying resin (rosin resin and C 5 The mass ratio of petroleum resin is 1:3), 0.6% diphenylmethane diisocyanate, 0.8% antioxidant 1010, 2.6% light calcium carbonate and carbon black;

[0031] (2) Put the raw materials prepared in step (1) into the internal mixer, knead at a temperature of 180-190°C for 2 hours, then stir for 10 minutes and then vacuumize for 30 minutes;

[0032] (3) Apply the mixture prepared in step (2) to a pressure roller to obtain a hot melt adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com