Improved pidgeon-process magnesium refining process

A process and a technology for smelting magnesium, which is applied in an improved technical field of the smelting process of magnesium by the Pidgeon method, can solve the problem of low filling coefficient of the reduction tank, affecting the heating speed of the heat energy distribution, and the heat energy utilization rate of the reduction furnace and the high production cost. no lesser problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

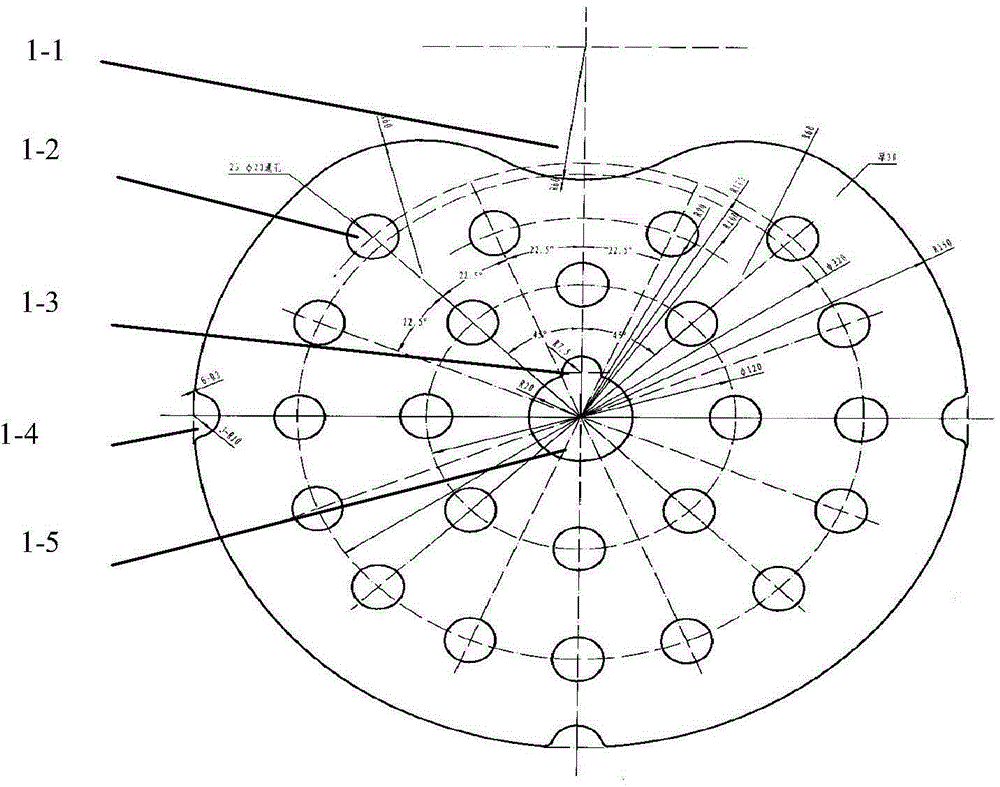

[0015] The improved Pidgeon method magnesium smelting process of the present invention is the same as the Pidgeon method magnesium smelting process of the prior art. The process includes calcining dolomite, adding ferrosilicon and fluorite, measuring ingredients, mixing and grinding, pressing into agglomerates, and The lump is put into a horizontal reduction tank for vacuum thermal reduction to generate crude magnesium, and then the rough magnesium is refined. The improvement point is to improve the shape of the lump, that is, to use a special pressing device to press the lump into a briquette-like disc-type lump. , the outer diameter of the briquette-shaped disc-shaped mass should be slightly smaller than the inner diameter of the vacuum tank, and evenly distributed round holes are reserved during pressing, which are called honeycomb holes 1-2, and the honeycomb holes 1-2 are formed in the disc-shaped mass. There is a central hole 1-5 in the center, and the rest are evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com