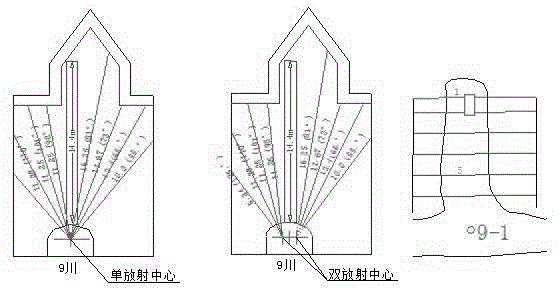

Double-emission-center cutting deep hole blasting technology

A technology of radiation center and deep hole, applied in blasting and other directions, can solve the problems of high cost of blasting chamber, difficulty in cutting chamber construction, large amount of mining and cutting engineering, etc., to achieve strong popularization and application value, reduce cutting cost, and simplify cutting The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Taking the seven ore belts in the Huashugou mining area of Jingtieshan Mine as an example, the test work of cutting deep holes and cutting small wells combined with trenching was carried out in the I-II ore bodies and V ore bodies in the Huashugou mining area. The success rate of cutting small well blasting reached 100%, and the cutting cost reached the expected index. The parameters of deep hole cutting are based on the physical and mechanical properties of ore rock, blasting technology theory and the integration requirements of mining and cutting. The design parameters of deep hole cutting are: hole diameter: Φ76mm mm, hole depth: 6-17m, hole bottom distance: 1.8-2.0m, Two rows of deep holes are arranged in the cutting well with a row spacing of 1.5m. The design parameters for cutting the small well are: small well section: 1.0*2.0m 2 , the height of the small well is determined according to the upper level, and the left and right sides of the center of the roadway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com